SuperTrak GEN3™

Specs, Components & Configurations

Built for the needs of today’s manufacturers.

The SuperTrak GEN3™ platform provides machine builders with a number of features to enable high performance automation with less risk.

Powered by linear servo motor technology, SuperTrak GEN3™ allows independent shuttle control with fast and precise motion, providing automation designers with an incredible amount of flexibility to increase productivity and minimize space.

Speed – up to 4 m/s

Increased speeds, lowered settling times, and rapid acceleration improve cycle times and overall productivity. Products get in and out of stations as quickly as possible spending more time in process and less time in motion.

Precision – +/- 0.01 mm repeatability

Increased precision means that stopper cylinders, locate tooling, and other add-ons may not be required; this results in decreased cycle times with less parts and less engineering. Ultimately your automation is more productive and requires less space on the factory floor.

Independent Shuttle Control

Independently control each shuttles velocity and acceleration, position, and destination, allowing for easier control of asynchronous motion.

SuperTrak GEN3™ Data Sheet

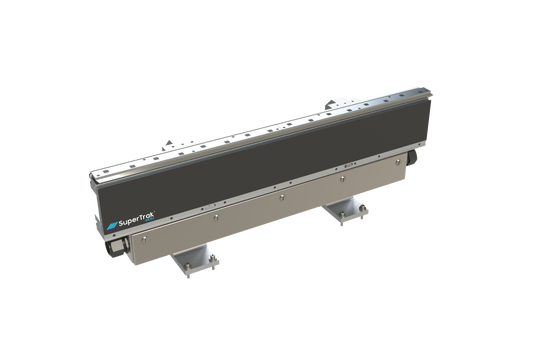

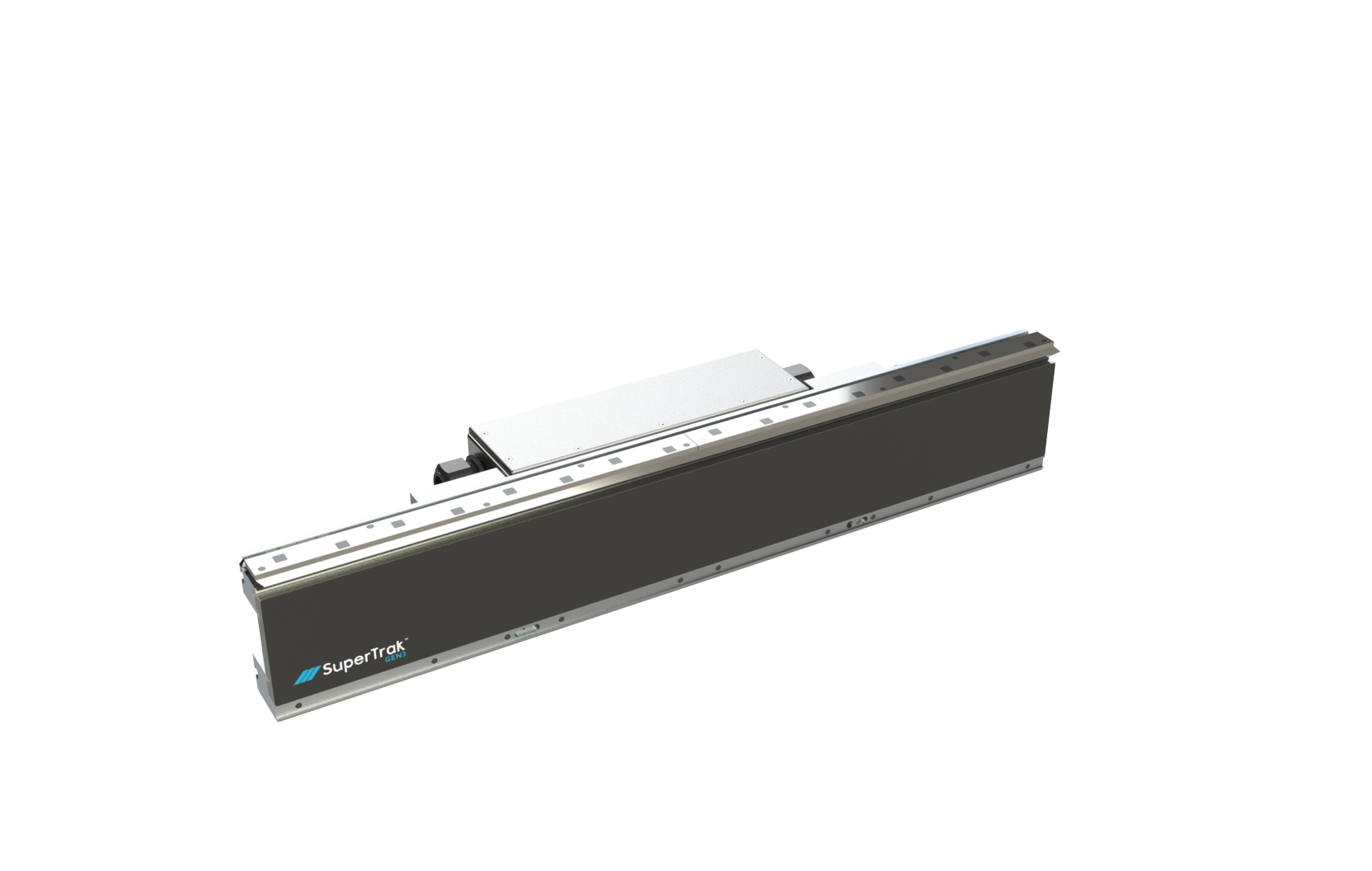

Straight Section

1000mm

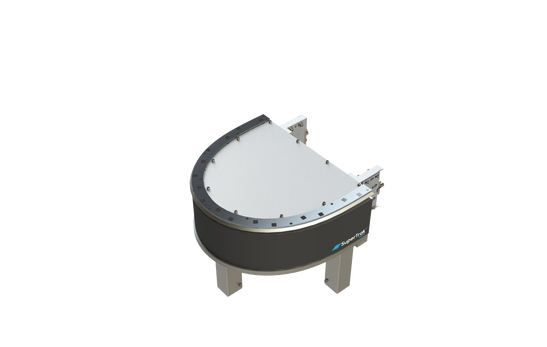

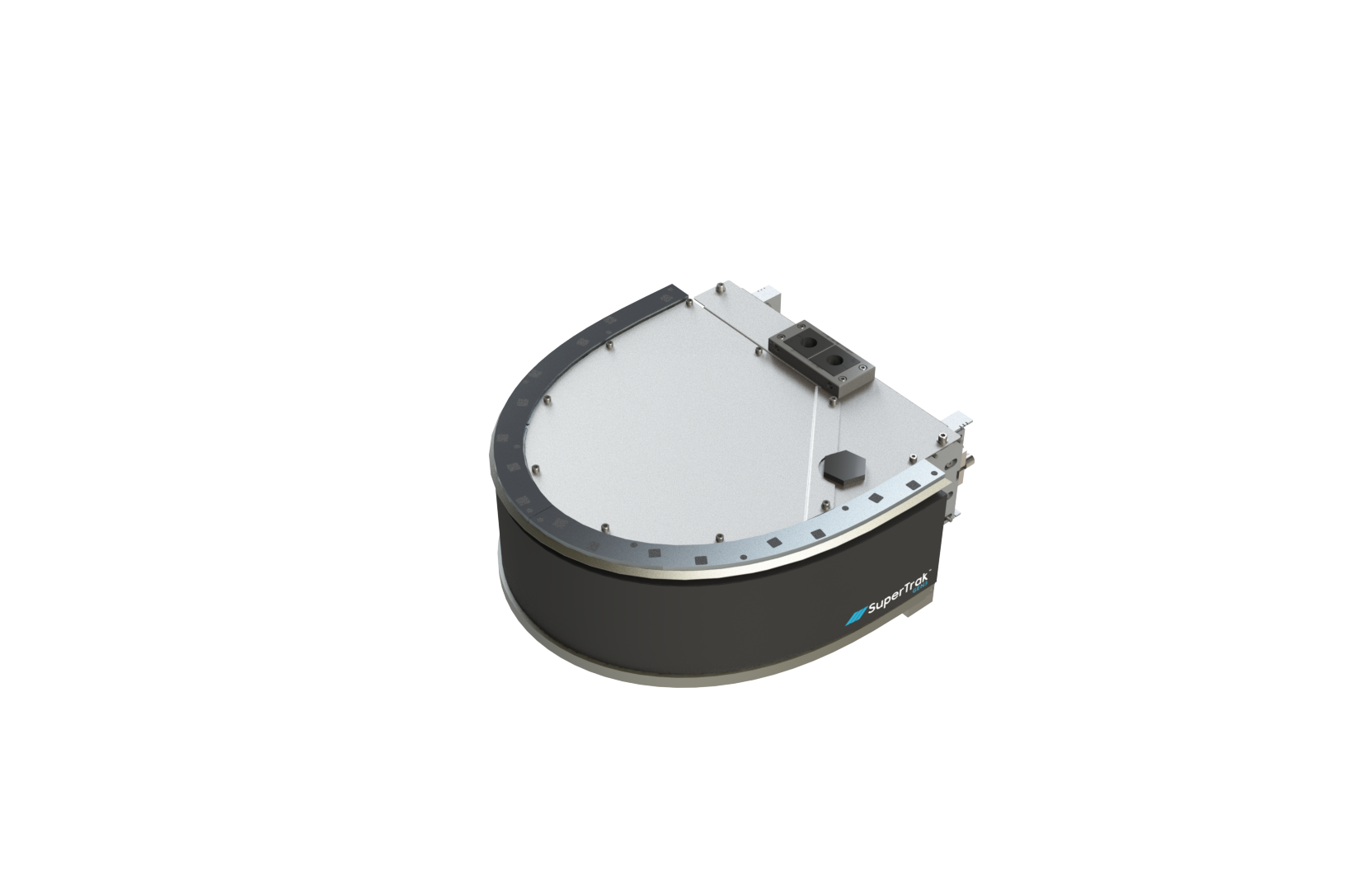

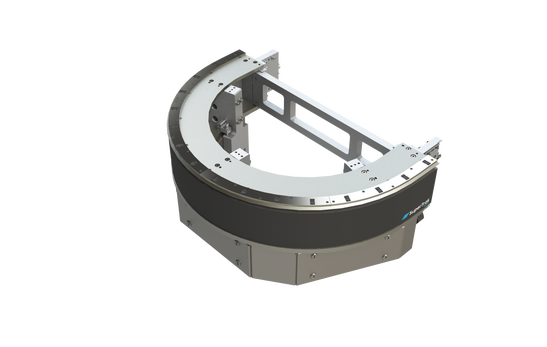

180° Section

500mm Diameter

800mm Diameter

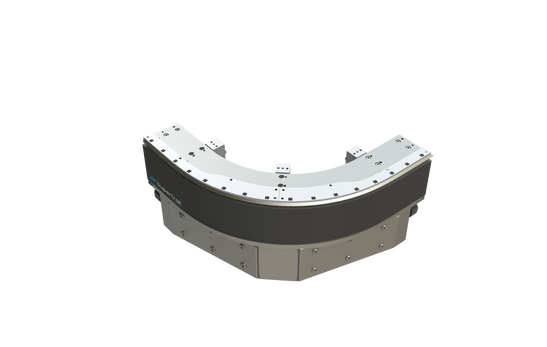

90° Section

600mm Radius

Product Fixture Width

152 up to 600mm

Maximum Speed

4 m/s

Acceleration

1G with 10 kg payload*

4G with 1 kg payload*

Payload

10+ kg per shuttle

Process on Curve

Full control

Shuttle Options

Standard shuttle configuration with 2 or 3 magnet array options

Communication

*Higher payloads and other protocols possible. Speak to a member of the SuperTrak Team for more info.

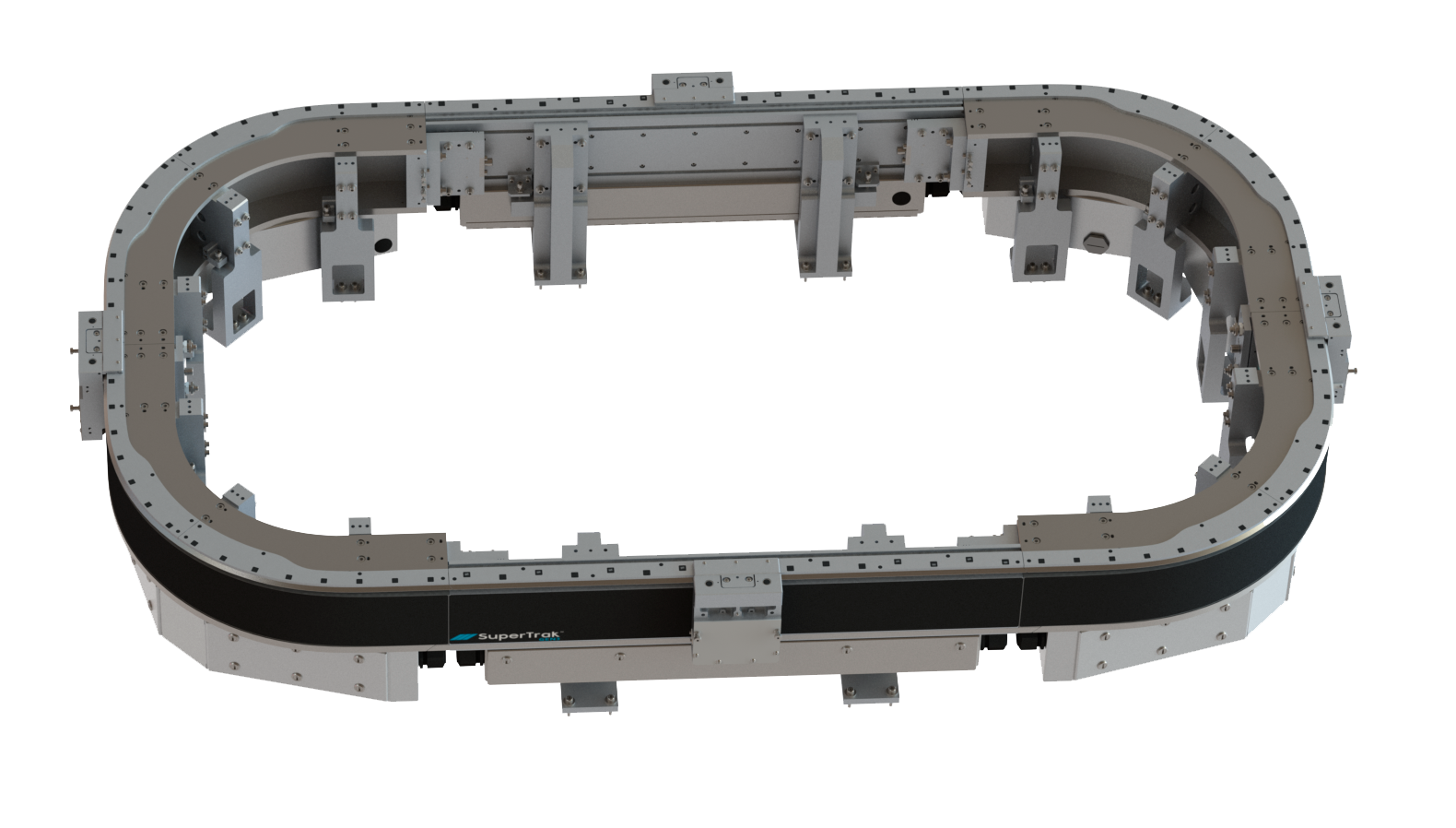

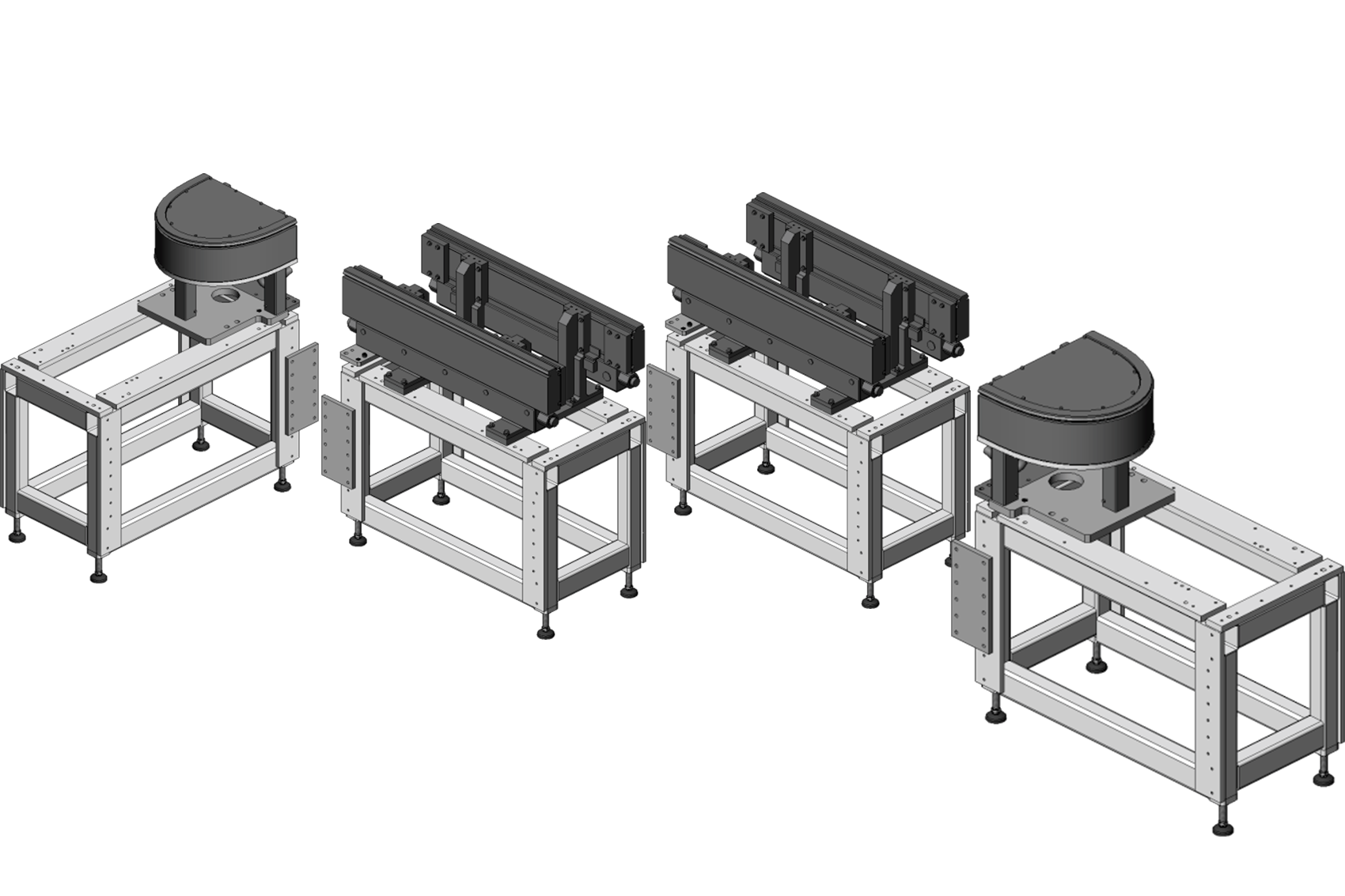

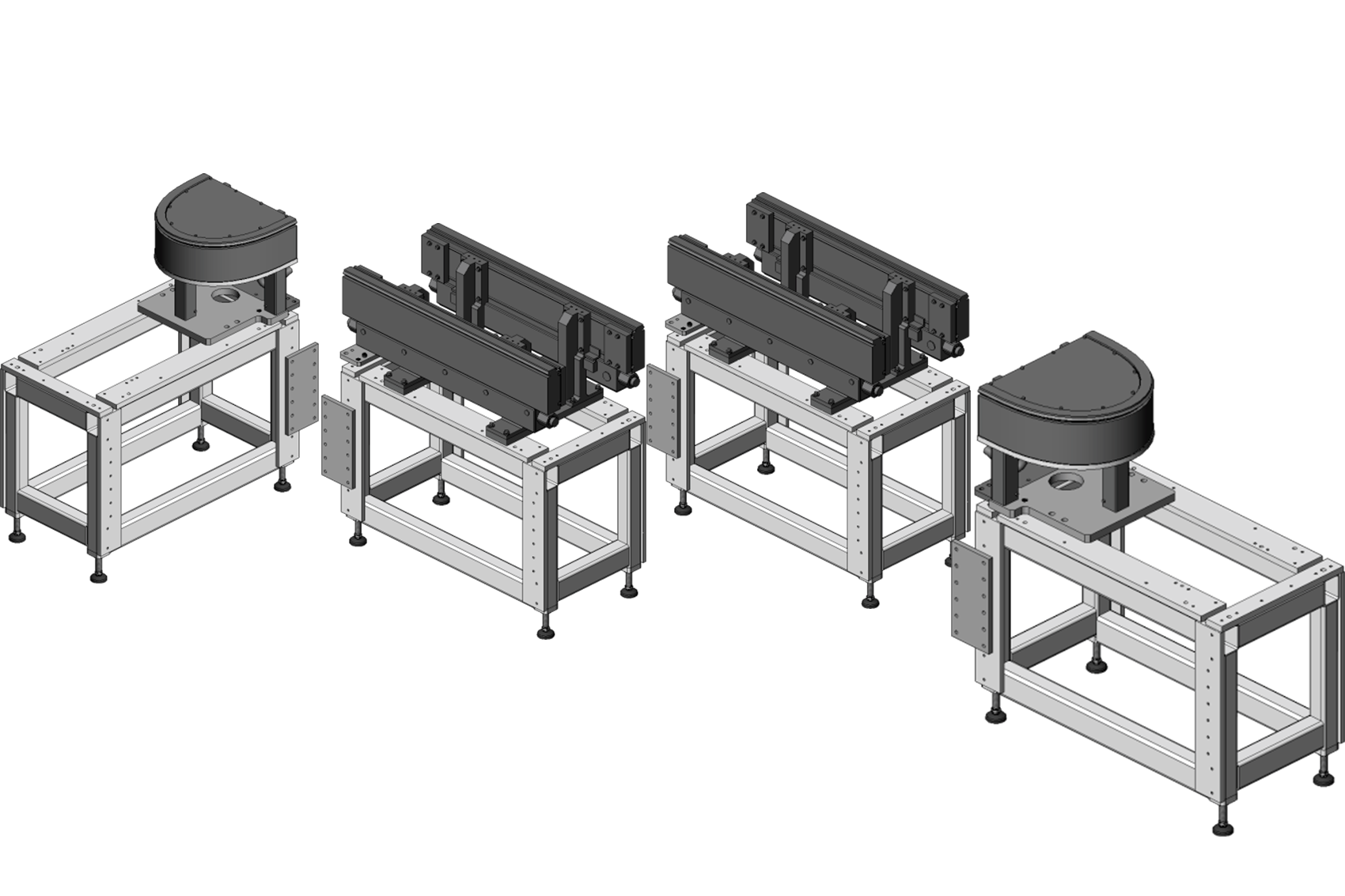

SuperTrak GEN3™ Components

Maximizing the functionality of your factory automation in the minimum amount of space is essential for today’s manufacturers and their industrial automation processes. The different configurations provide the flexibility for tooling to be mounted on the inside, outside, overtop, or underneath.

90° Section

180° Section (500mm Diameter)

Low Profile 180° Section (500mm Diameter)

180° Section (800mm Diameter)

Straight Section

Low Profile Straight Section

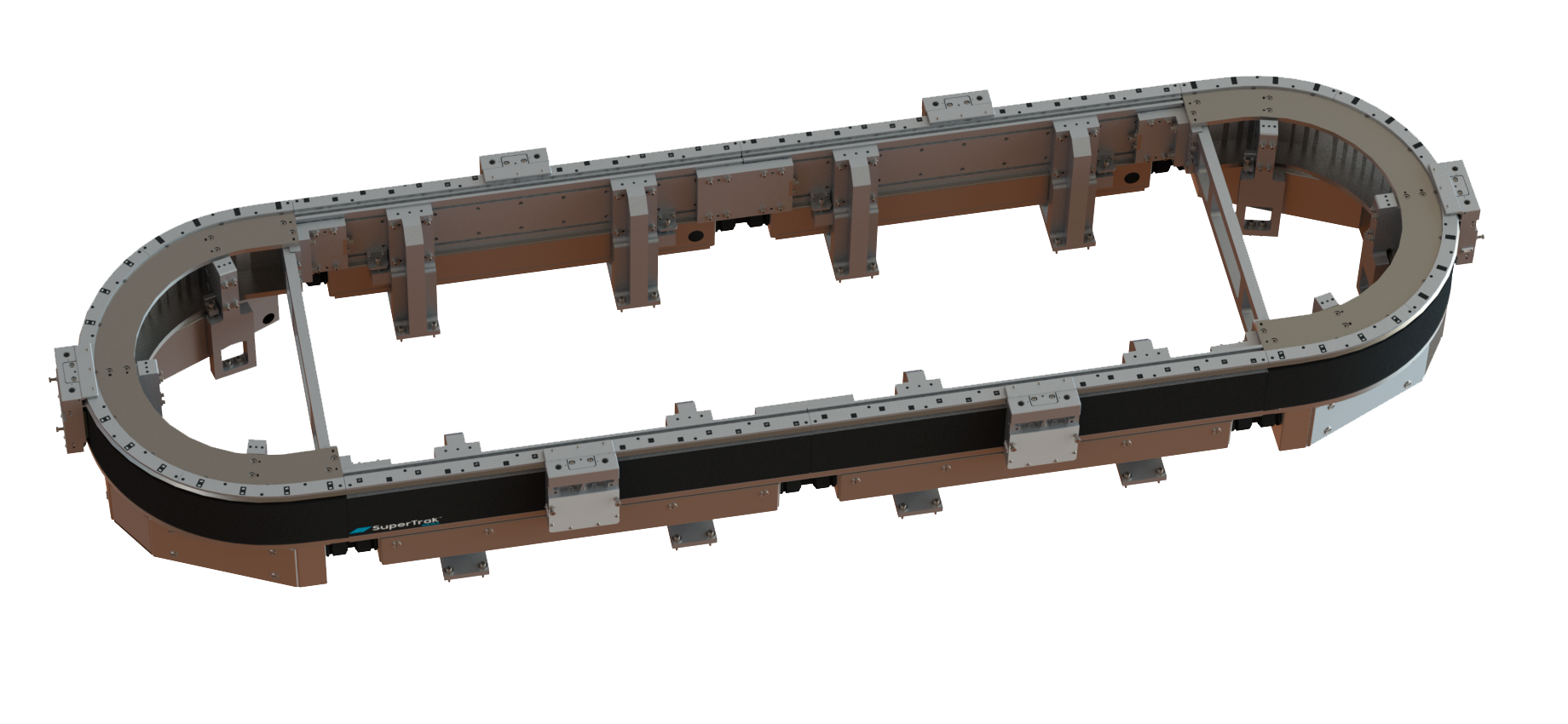

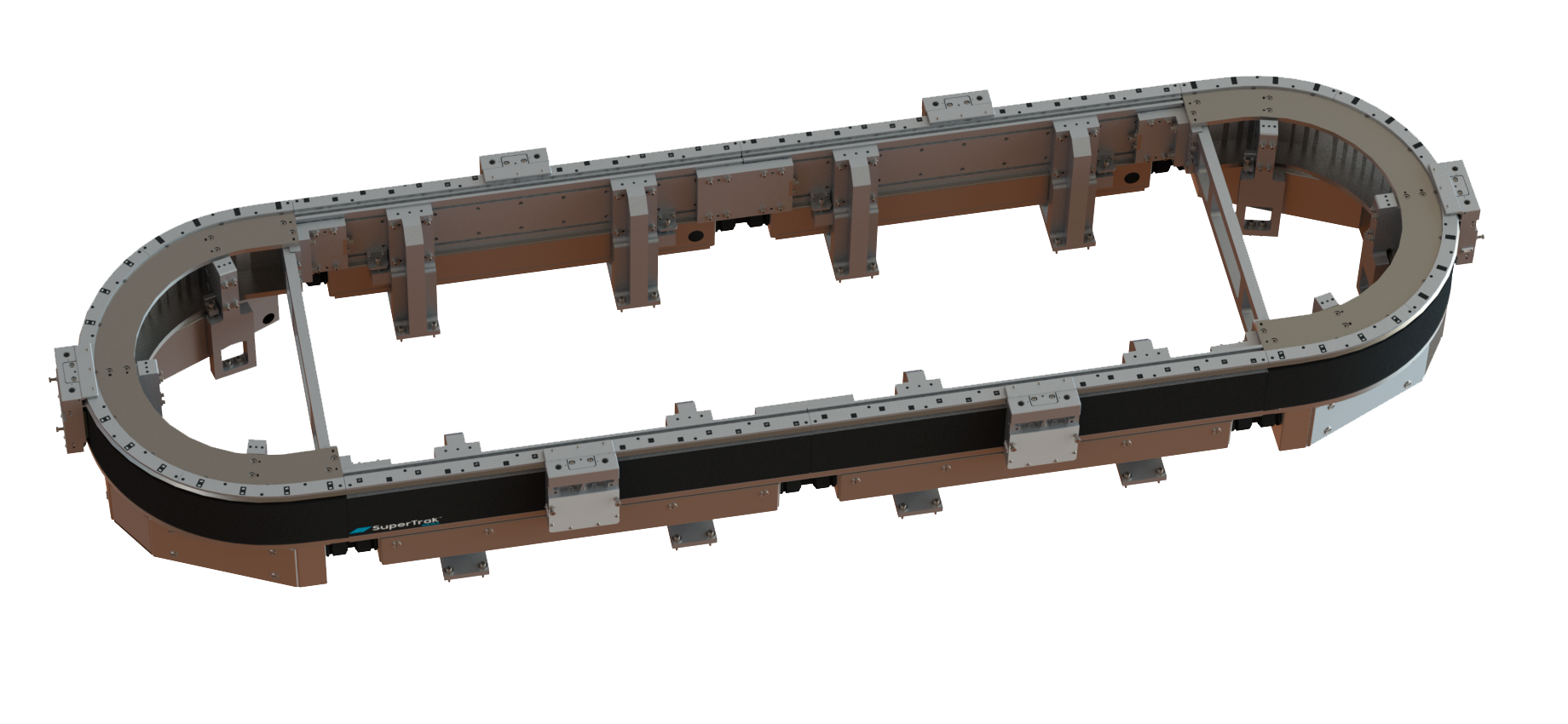

SuperTrak GEN3™ – 90° Configuration

The new 90° configuration offers the same floor saving space as a servo or indexing dial. The 90° curved sections allow for even more configuration options such as a squared circle or rectangle. When using this configuration, the system can grow in both length and width. Two 90° sections back to back allow for a system that is 1200mm wide. Manufacturers can fit even more tooling on the inside to minimize system footprint.

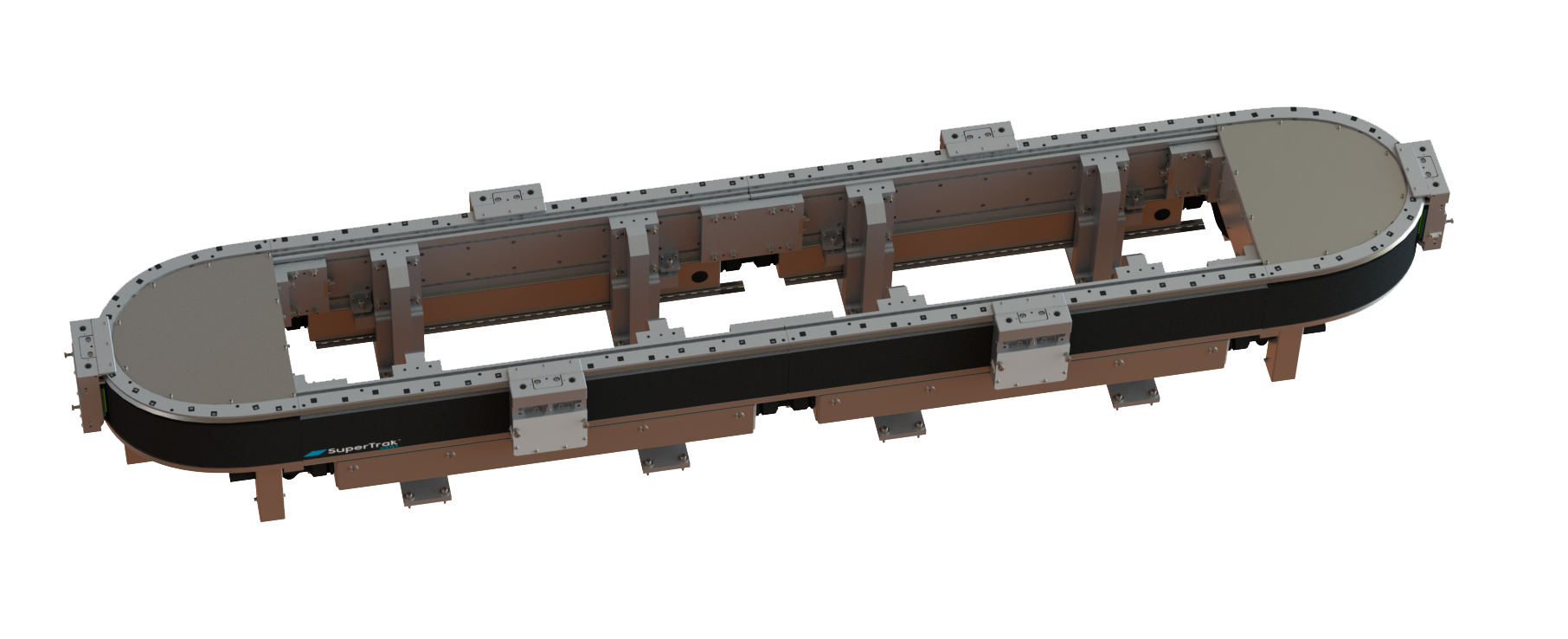

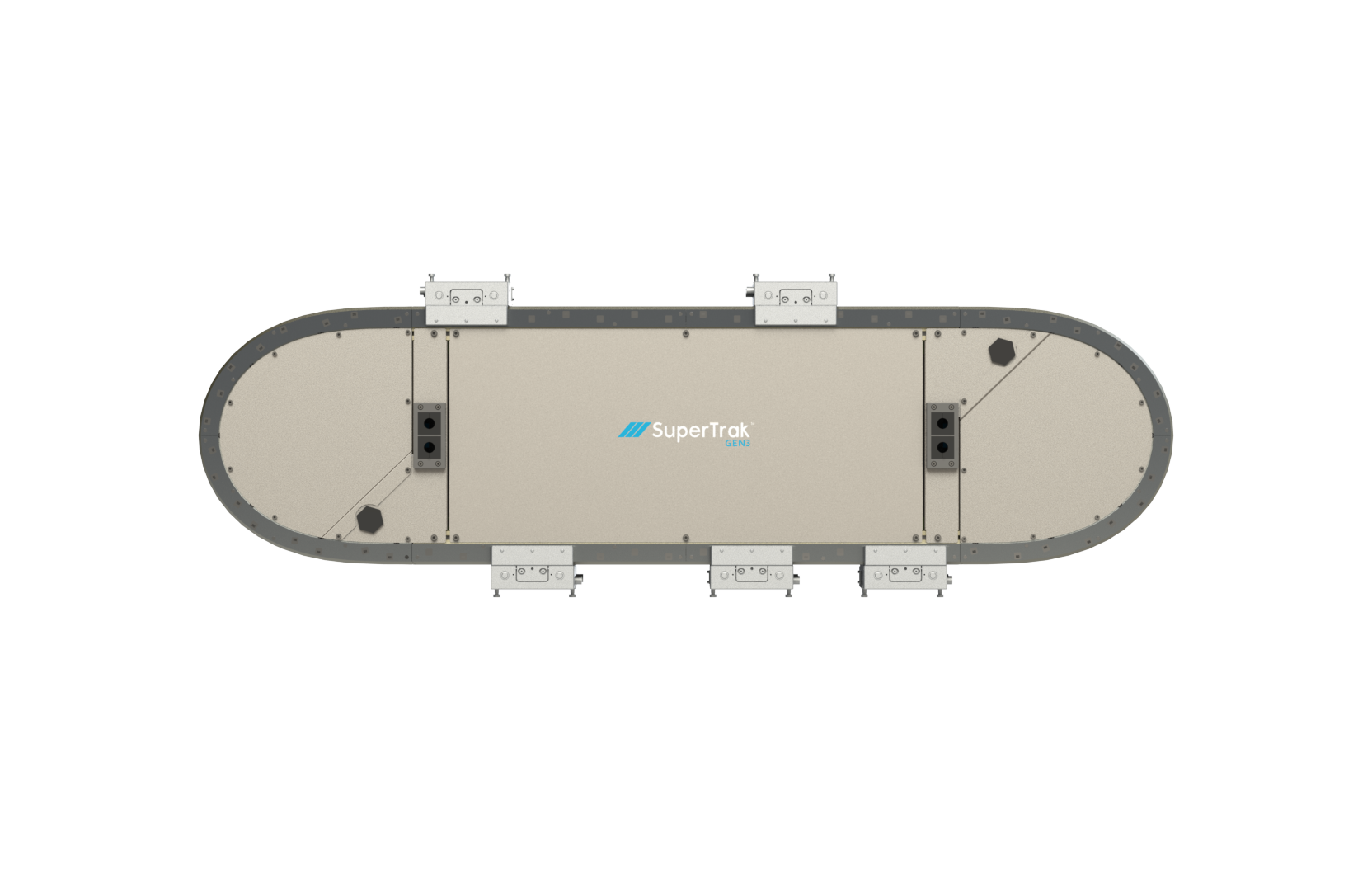

SuperTrak GEN3™ – 800mm Configuration

Additional space on the inside of the conveyance platform allows manufacturers many options to mount tooling on the inside. This helps minimize the amount of space your factory automation requires on the factory floor.

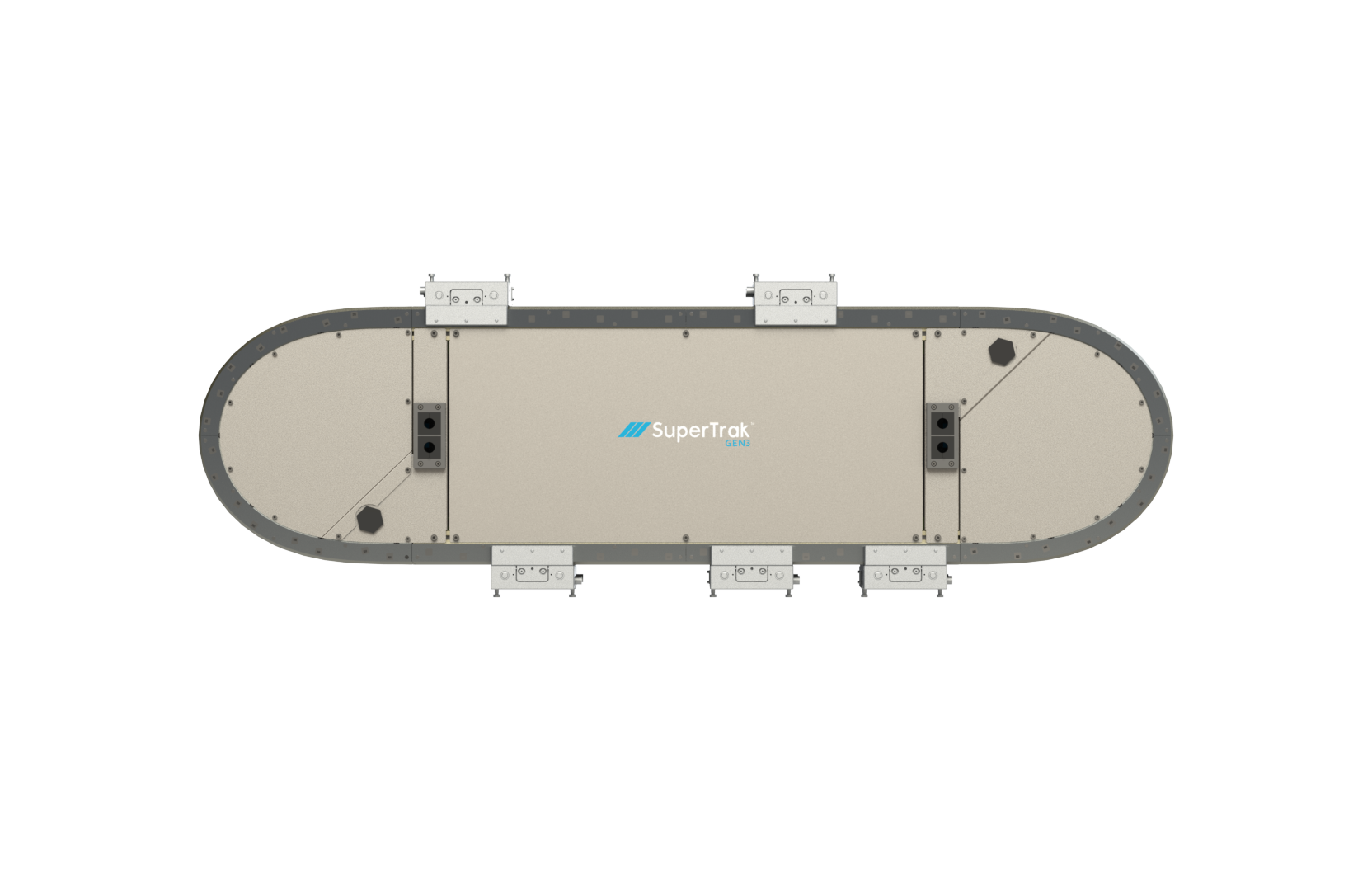

SuperTrak GEN3™ – 500mm Configuration

Offers manufacturers options to mount tooling on the outside of the conveyance platform.

Flexible Configurations

Being able to easily scale your business is essential for the success of today’s manufacturers. The flexible nature of the SuperTrak CONVEYANCE™ platform allows manufacturers to expand your systems by easily adding additional modular sections as your business grows and as products change. Easily reconfigure the functionality of the conveyance platform as business requirements change.

Your team of engineers and designers can quickly scale system programming for additional stations and processes utilizing target routing within our TrakMaster™ software. All of this high-performance capability is achieved with less effort because of the amount of integrated functionality that’s packed into the platform. Scalability is essential for the success of your business.

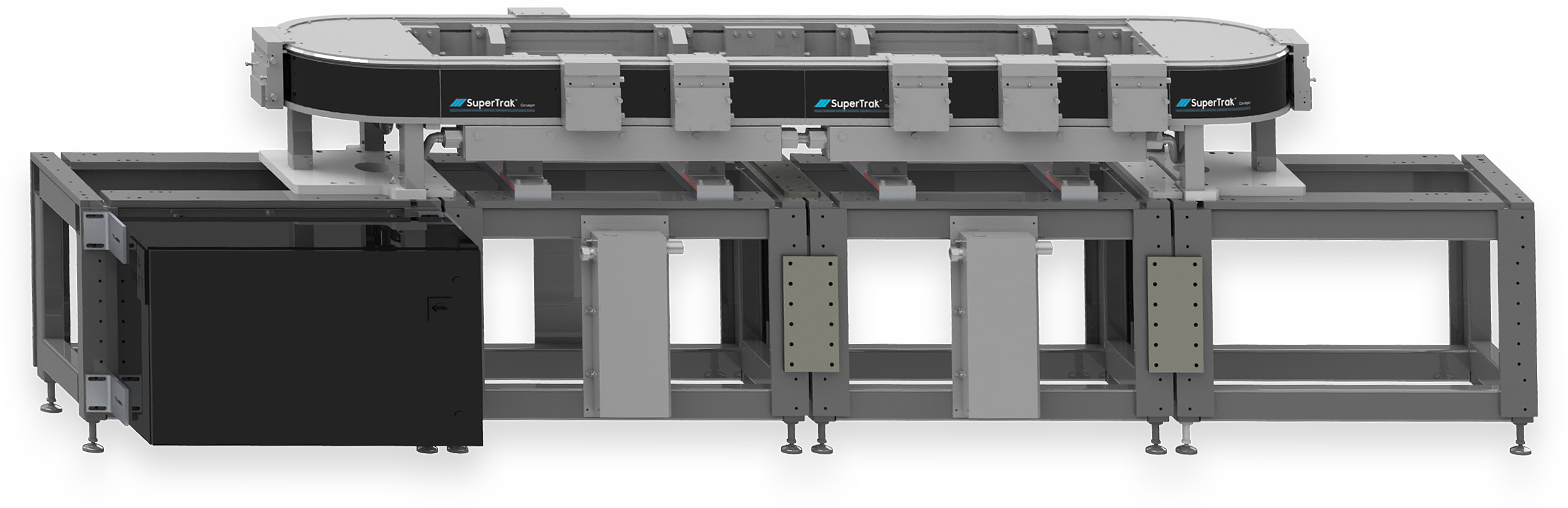

SuperTrak GEN3™ – Horizontal

Best suited for applications where Smart Conveyance is an effective solution.

With a 10+kg weight capacity for each shuttle, the platform’s independent shuttle control, speed, and precision delivers high performance capability with less engineering by utilizing the amount of integrated functionality packed in the platform.

Popular across industries including, medical device manufacturing, pharmaceutical, automotive and consumer products.

SuperTrak GEN3™ – Vertical (Over/Under)

Best suited for manufacturing processes with a one-directional part flow. The over/under configuration has a slightly lower weight capacity of 4kg per shuttle on curves but maintains the 10kg capacity on straights. Utilized in applications where floor space is at a premium, the over/under configuration has seen much success in automotive battery assembly and packaging applications.

Download SuperTrak GEN3™ Design Package

Start designing your system with SuperTrak GEN3™ to discover the benefits of Smart Conveyance.

By thinking of your conveyance early in the design phase, you can fundamentally change the way you build your system, reducing complexities and creating high-performance automation with less risk.

Resources

SuperTrak GEN3™ Brochure

The SuperTrak GEN3™ conveyance platform enables the development of world leading automation for the most demanding applications.

Engineers Guide to Smart Conveyance

Automation can be complex. Smart Conveyance doesn’t have to be. Download the Engineers Guide to see how Smart Conveyance can bring significant benefits to automation design and performance.

Case Study: Creating Highly Flexible Automation

The Larisys Group learned about SuperTrak CONVEYANCE™ several years ago and saw the technology as disruptive because of its speed, precision, compact design, and its ability to be easily reconfigurable.