A high-performance magnetic conveyor for lean and compact manufacturing automation.

SuperTrak VERTICAL10™ systems can carry up to 10kg per shuttle on top of the track. They are designed to provide better access to the assembled product and enable unidirectional product flow.

The independent shuttle control of SuperTrak VERTICAL10™ allows machine builders to reduce the size of their assembly machine even more than with horizontal configurations thanks to the expanded product access for both tooling and operators.

SuperTrak VERTICAL10™ is the new standard for compact lean automation and is perfectly suited for cleanroom applications.

Machine builders and manufacturers can design, develop, and deploy complex assembly automation while reducing engineering complexities and risks—all without sacrificing performance. Reduce machine size and improve product reach using this asynchronous magnetic conveyor.

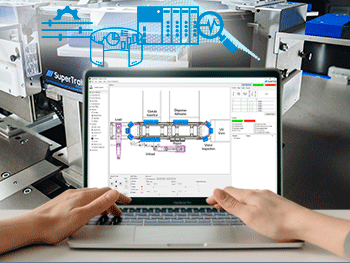

Specifications, Components and Configuration

Designed to serve compact, precise, and flexible assembly automation, SuperTrak VERTICAL10™ is an asynchronous conveyor available in various system lengths.

SuperTrak VERTICAL10™ makes operations more compact and reliable.

This magnetic conveyor has a proven ability to allow the design of more compact industrial automation while still benefiting from its reliability and flexibility.

Manufacturing automation can now be leaner thanks to SuperTrak VERTICAL10™.

Simplify design & integration.

Use the SuperTrak CONVEYANCE™ integrated functionality to reduce complexity and risks.

Reduce machine size.

Reduce floor space and improve productivity using SuperTrak CONVEYANCE™.

Deploy automation faster.

Simplify engineering and get to market faster using SuperTrak CONVEYANCE™ products.

Get in Touch

Fill out the form below to get in touch with a SuperTrak CONVEYANCE™ expert.