Featured Posts

For certain applications implementing a foundational technology that allows for both asynchronous and synchronous zones on the same platform is beneficial.

For certain applications implementing a foundational technology that allows for both asynchronous and synchronous zones on the same platform is beneficial.

For certain applications implementing a foundational technology that allows for both asynchronous and synchronous zones on the same platform is beneficial.

Implementing new technology is easier than you think. Here's why you should prioritize selecting the right conveyance technology partner.

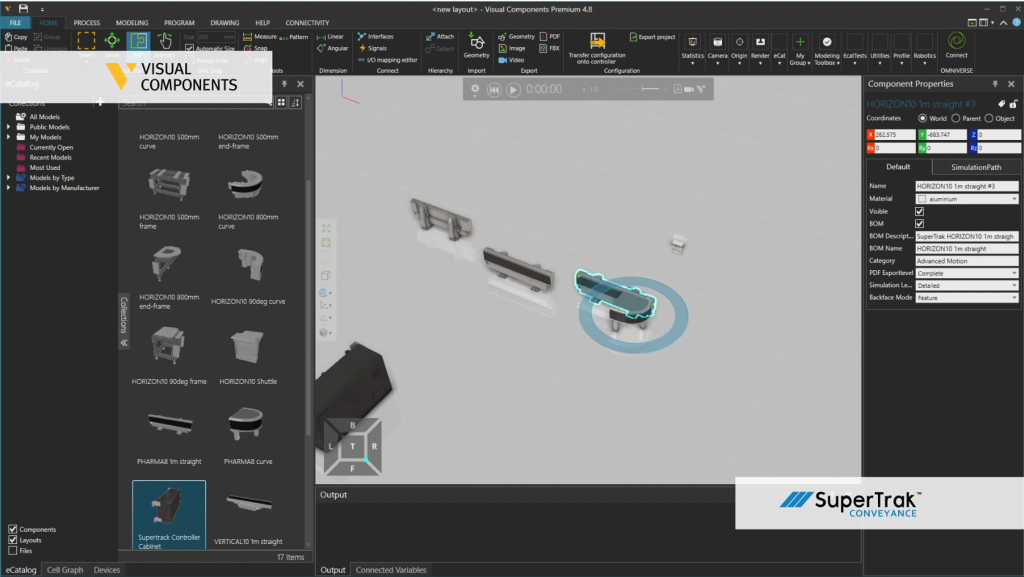

Simulations are beneficial for designing efficient conveyance with asynchronous automation. When done early in the design phase, these help ensure the system uses as little tooling, and as little factory footprint as possible.

How you can set yourself up for success by thinking of conveyance early in automation design.

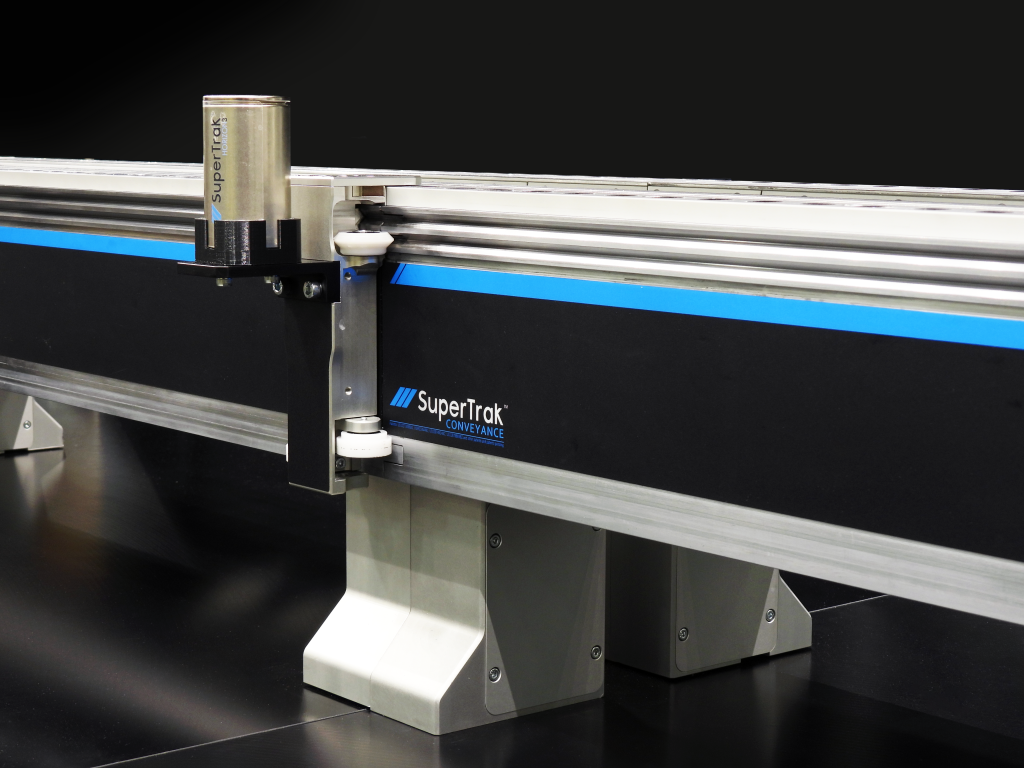

How Smart Conveyance enables manufacturing efficiencies in the development and performance of automation solutions using asynchronous motion.

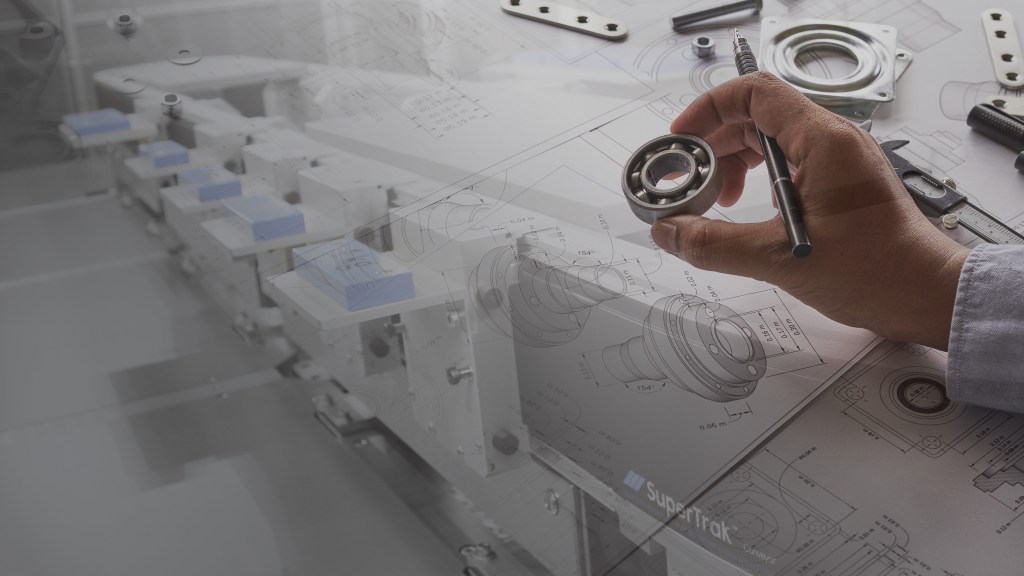

Companies are still feeling the impact of supply shortages that initially spiked throughout the pandemic. Here's how our lead time directly impacts your automation process.

If you’ve ever designed or deployed an automation system, you know that there are a lot of things that can go wrong. The good news is, there are ways to mitigate risks from both the perspective of the system designer as well as the business leader.