In manufacturing, we often talk about scaling up to meet market demand. But what happens when supply can’t keep up with demand?

Market and supply chain uncertainty can have a significant impact on your business. The forces that determine if you will be able to meet your throughput goals can be outside of your control. When you build a automation system that can scale up but can’t scale down, you affect your profitability and your ability to adapt.

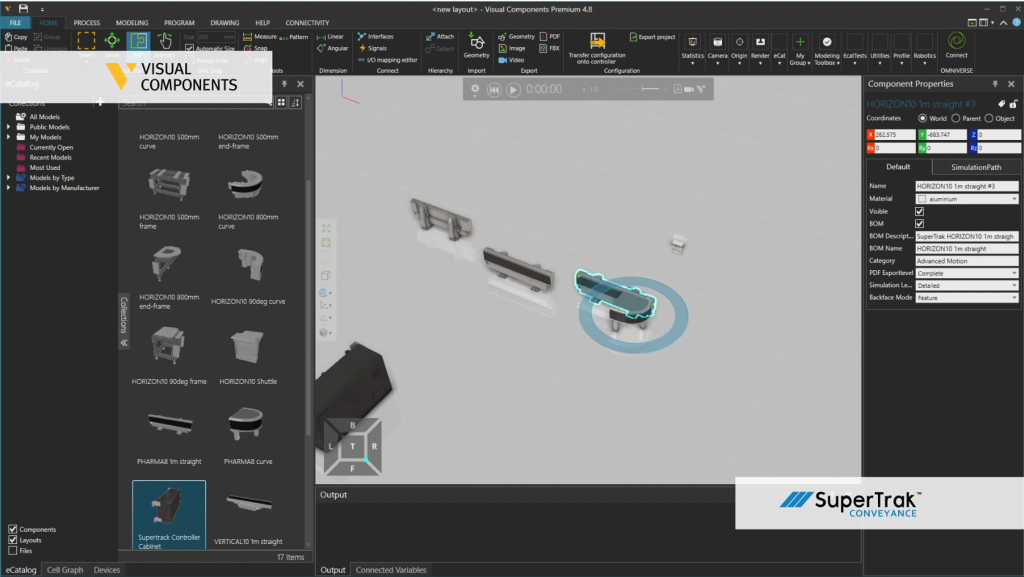

Smart conveyance and a modular foundation make your automation systems scalable and adaptable – whether you need to ramp up or scale down production.

Demand Is Up, Supply Is Down

The demand is there, and you’ve carefully planned your production to meet that demand but forces outside of your control are limiting your ability to fulfill that demand and reach your throughput goals. So how do you move forward?

The COVID-19 pandemic changed many things but “[c]onsumers will continue to want low prices (especially in a recession), and firms won’t be able to charge more just because they manufacture in higher-cost home markets.” (HBR, Sept-Oct 2020). The need to use your manufacturing capabilities efficiently will remain key for your success.

Industry Shortages

Regardless of the industry in which you operate – food and beverage, medical, or automotive – it’s likely that you’re experiencing a shortage in your supply chain. A survey from the Institute for Supply Management found that all industries were experiencing “record-long lead times, wide-scale shortages of critical basic materials, rising commodities prices, and difficulties in transporting products.” (Reuters, May 2021). This is a new challenge that we don’t often face in manufacturing.

We’ve seen production and demand increase steadily for years but now we’re being asked to move in the opposite direction. And we don’t know when those supply chain issues will be resolved.

Long Term Effects:

The effects we are experiencing in our supply chain aren’t guaranteed to end with the pandemic either. “Covid-19 will certainly have latent effects on organizational resilience throughout 2021, directly and indirectly shifting the way organizations do business,” Jim Yarbrough, global intelligence program manager at BSI [a London, UK based standards and supply chain intelligence firm] said in a statement.” (Supply Chain Quarterly – April 2021). Your business will continue to be tested and you will need to find ways to adapt to remain profitable post-pandemic.

Smart Conveyance and Organizational Resilience:

Your business’ resilience is going to separate you from your competition and your resilience is directly impacted by your ability to scale up and down quickly and efficiently. We often focus just on the ability to scale up but this supply chain shortage issue we’re all facing has shown us the gap in that thinking. We need to do more than just expand to meet increased demand. We need to be able to temporarily scale down our production to maintain profitability.

One way of doing that is to invest in systems that allow for easy redeployment. We explored redeployability in manufacturing system design a little while ago (you can read about it here: Redeployability: The Secret to Adapting in Manufacturing Automation) and these supply chain shortages that have affected us all have reinforced that idea. A system that is easily scaled up can be just as easily scaled down. No matter how long these supply chain issues continue, a modular system can expand and contract to reduce waste.

We’re likely to see more ripple effects like this supply shortage in a post-pandemic world. Ones we might not be able to predict and plan for. However, we have the technology to ride whatever waves come next. Using smart conveyance platforms is the single best way to futureproof your business. If you haven’t already, what’s stopping you from investing in a modular smart conveyance system?

See the difference a modular system can make to your business.