When designing a new assembly automation system, leveraging the asynchronous motion of individually controlled shuttles enables optimizing the use of each station (by reducing the number of stations and/or amount of tooling) leading to major cost and space savings on complex processes.

However, for certain applications such as high-speed infeed/outfeed, web feed, glue dispensing, or on-the-fly part insertion, you might want to implement a foundational technology that allows for both asynchronous and synchronous zones on the same platform. In such cases, system designers can leverage the benefits of their asynchronous system with some types of other equipment that inherently works continuously, like a regular conveyor belt or a star wheel.

Asynchronous conveyance offering synchronous zones, isn’t unheard of, but it is typically very hard to implement and doesn’t always serve every PLC. The ideal solution to this problem is an easy-to-implement Smart Conveyance asynchronous system that features sync zones and works with standard EtherCAT™, ProfiNet™ IRT, Ethernet/IP™ PLC master signals..

Enable Faster Cycle Times at Particular Stations While Benefiting from Asynchronous Motion on the Rest of the System

The SuperTrak GEN3™ Easy Sync feature enables the synchronization of shuttle motion to an external axis or input. It provides the opportunity to use cyclic synchronous tooling that is mechanically coupled to the master axis in user-designated regions of the track, called sync zones.

Sync zones enable synchronized motion at a constant velocity with a fixed pitch (to be used with star wheels or other fixed-pitch product transfer applications).

Sync zones also facilitate synchronized motion at a constant velocity with a variable pitch. In these cases, the external master system sends an index pulse signal or network output via fieldbus so that the next available shuttle synchronizes by the time it reaches the designated synchronous area.

To summarize, a system using SuperTrak GEN3™ as its foundation has the capability to synchronize efficiently with continuous-motion equipment in some regions while still benefitting from asynchronous motion everywhere else.

That Seems Complicated to Implement?

We Made it Simple For You!

As a team composed of engineers and machine builders ourselves, we understand that adding complexity into the programming of your system increases the risks, so the SuperTrak CONVEYANCE™ platform takes care of the motion for you.

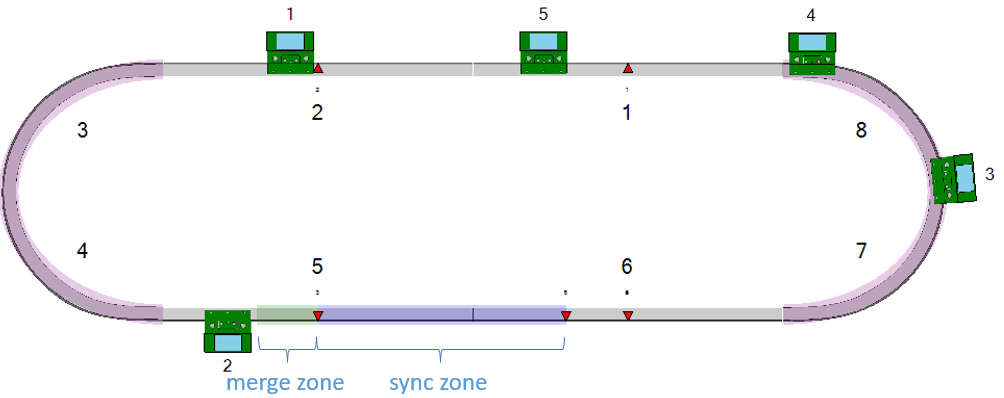

As explained earlier, Easy Sync enables synchronized motion in one or more specified sync zones on the system. Shuttles move asynchronously before and after every sync zone: This provides the opportunity for shuttles to properly merge and buffer prior to the sync zone and exit to a predetermined target position beyond the sync zone.

SuperTrak GEN3™ automatically handles transitions from asynchronous motion to sync zones using a merge zone that the platform’s TrakMaster™ software configures automatically based on shuttle motion parameters. It also automatically handles the departure from a sync zone to asynchronous motion. Shuttles can enter and exit synchronous areas on the fly!

We even made it easier to manage recovery: Upon restart, shuttles automatically move either to a valid sync zone alignment position or to an un-obstructing, asynchronous position.

With Easy Sync You Can Create Even Leaner Automation Systems

On certain processes, working continuously can simplify tooling on a station. Here is an example application where a canula is loaded on a syringe. With 12 parts per shuttle, we can reach 450ppm on a SuperTrak GEN3™ based system that remains relatively simple and short. However, to reach that throughput, the canula insertion process requires two parallel stations and a certain level of motion complexity.

With Easy Sync, these two stations can be replaced by one star wheel, simplifying the integration and reducing cost and size. Motion is synchronous in this region of the track, while the remainder of the track remains asynchronous to enable optimization of each process station and an overall simplification of the system.

How Do I Set up Easy Sync On My SuperTrak GEN3™ Platform?

Setting up a sync zone on an existing system only requires changing a few parameters using TrakMaster™ software.

• Create a Target: Just like setting stations and processes on SuperTrak GEN3™, a sync zone starts at a target set by the user. This is done in a few clicks in TrakMaster™: Enter the position of the new target on the track and give it a name.

• Create a Move Configuration: Shuttles need a move configuration to exit the sync zone. In most cases you just need to set a target to go to, although you can also choose a different shuttle velocity or acceleration if you need to.

• Create a Sync Zone: Set the target at which the sync zone starts, the sync zone length, the move configuration to exit, and the shuttle velocity to merge.

At this step, the TrakMaster™ software automatically creates the sync zone, its merge zone, and configures the track to operate shuttles with the appropriate motion. After configuring your master signal input and making sure shuttles are sent to the appropriate targets, you can run the track.

As an added benefit, as with all SuperTrak CONVEYANCE™ platforms, Easy Sync works with standard EtherCAT™, ProfiNet™ IRT, Ethernet/IP™ PLC master signals. We also provide training implementing and using Easy Sync through our SuperTrak Academy program.

Want to learn more about Easy Sync functionality? Contact our Applications Team for a demo!