Reduce Engineering Complexity and Risks

Considering conveyance early in the design phase of your factory automation fundamentally changes the way you design your system. It can also lead to a faster path to production through simple system design and integration. Conveyance is the foundation of your factory automation and touches practically every component, helping engineers, system designers, integrators, and manufacturers accomplish high-performance automation with an improved ROI.

Smart Conveyance has several benefits including faster times to market, simplified tooling, reduced floorspace, and an overall reduction in engineering hours. Through the use of a streamlined system design and integration process, at SuperTrak CONVEYANCE™, we get automation systems up and running as much as 40% faster than those built on traditional conveyance.

The How:

System Simulations

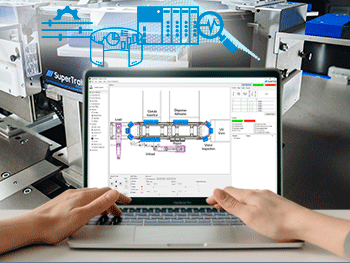

Creating a simulation of your system early in the design phase can help you to optimize processes, evaluate performance requirements, and understand energy consumption.

You can easily create simulations on your own or with help from our applications engineering team using the platform’s TrakMaster™ software. Simulations demonstrate precisely how an application will perform on the final system. Whether conceiving a new application or adapting to a last-minute change in requirements, this digital twin can evolve with your project and be loaded directly onto the SuperTrak CONVEYANCE™ platform anytime.

Accurate motion simulations early in the design phase remove engineering complexity and allow system designers to optimize design and performance for a better ROI

Straightforward Configuration

The straightforward configuration of the SuperTrak CONVEYANCE™ platform’s integrated functionality removes risks and reduces engineering hours associated with complex programming via its tested and proven capabilities. SuperTrak CONVEYANCE™ systems also have built-in PLC function blocks that provide intuitive interfaces for functions such as configuring shuttle motion, accessing data, and setting parameters.

Integrated Functionality

The platform’s integrated functionality removes the barriers inherent to asynchronous motion. SuperTrak’s controller software can be configured with TrakMaster™ software and/or live via the PLC. Setting motion configurations and targets using TrakMaster™ software synchronizes shuttle release, while the PLC enables faster implementation and easier diagnostics.

Targets

Configure the destination of each shuttle at each step of the process.

Position Triggers

Ability to trigger external devices to perform actions on the fly.

Pre-Arrival Notifications

Communicate timing so that tooling is ready to work as soon as the shuttle arrives.

Pre-Stops

Ensure all approaching shuttles are held back from the process target location if already occupied.

Interface I/O

Use pre-defined input/outputs or configure SuperTrak parameters to access them more easily.

Offsets

Allows for straightforwardly optimizing the system and can easily activate offsets from PLC

These features contribute to reduced engineering and integration hours, allowing automation systems to enter production faster and realize ROI sooner.

Reduce Engineering Complexity and Risks

Considering conveyance early in the design phase of your factory automation fundamentally changes the way you design your system. It can also lead to a faster path to production through simple system design and integration. Conveyance is the foundation of your factory automation and touches practically every component, helping engineers, system designers, integrators, and manufacturers accomplish high-performance automation with an improved ROI.

Smart Conveyance has several benefits including faster times to market, simplified tooling, reduced floorspace, and an overall reduction in engineering hours. Through the use of a streamlined system design and integration process, at SuperTrak CONVEYANCE™, we get automation systems up and running as much as 40% faster than those built on traditional conveyance.

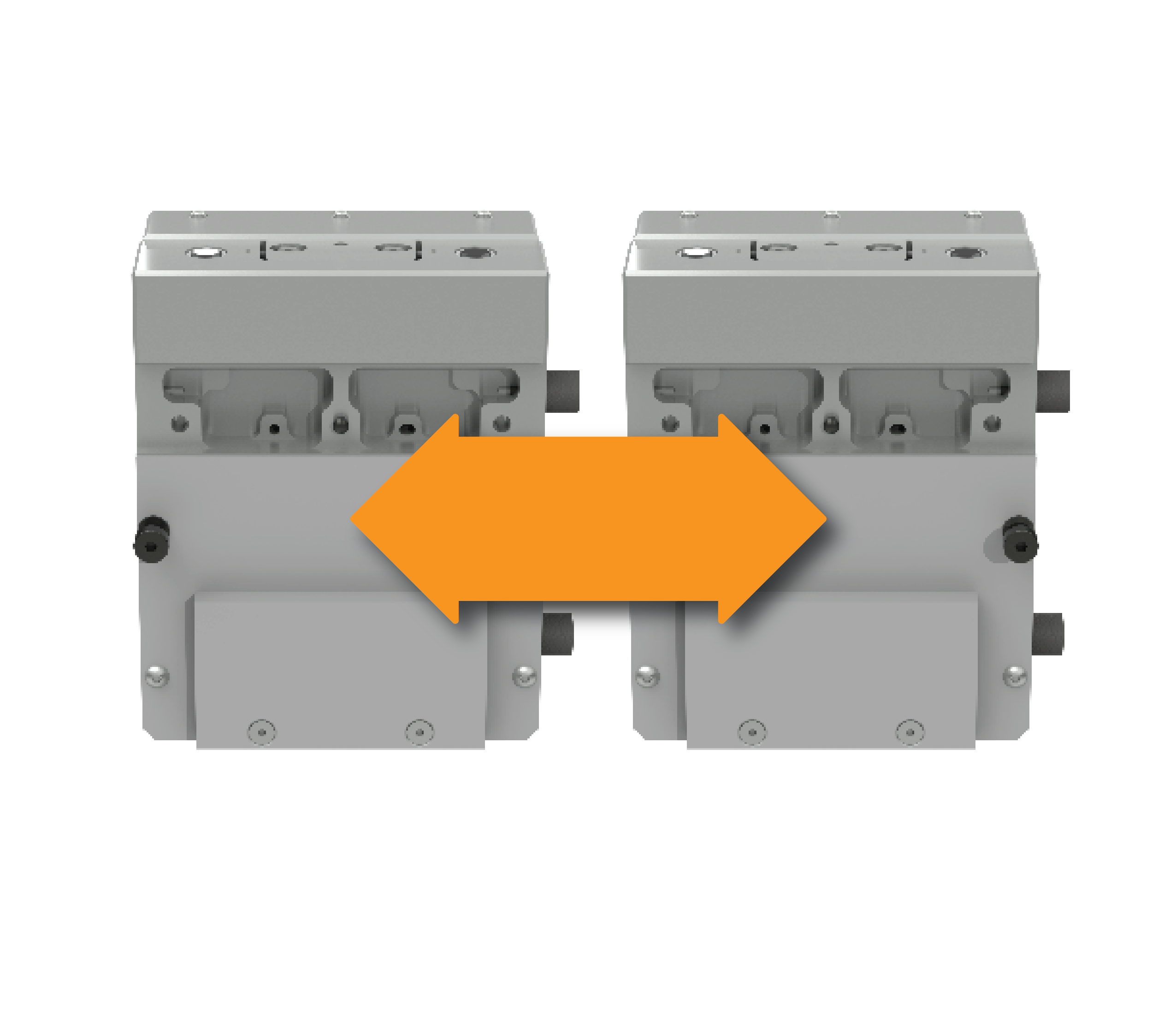

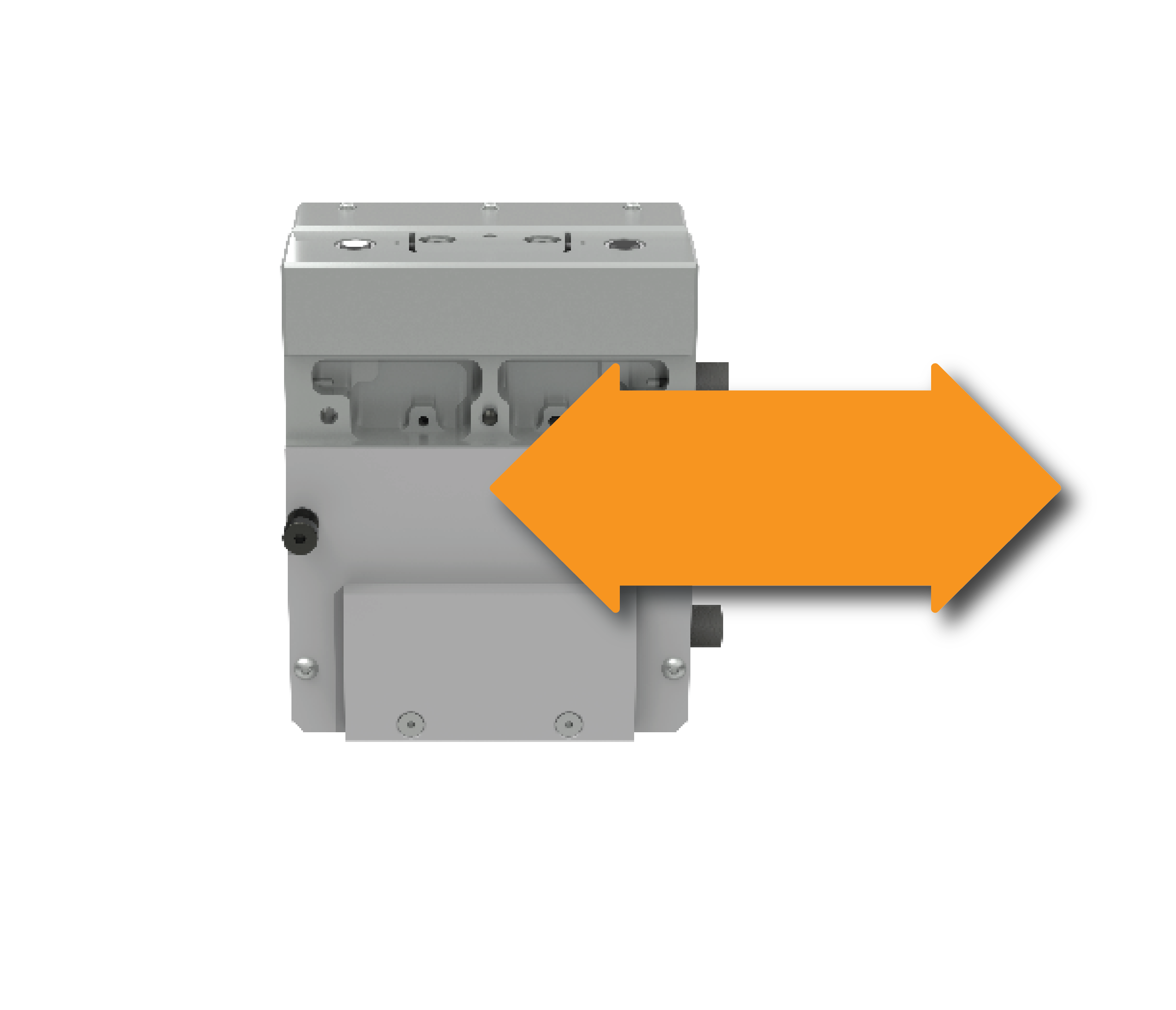

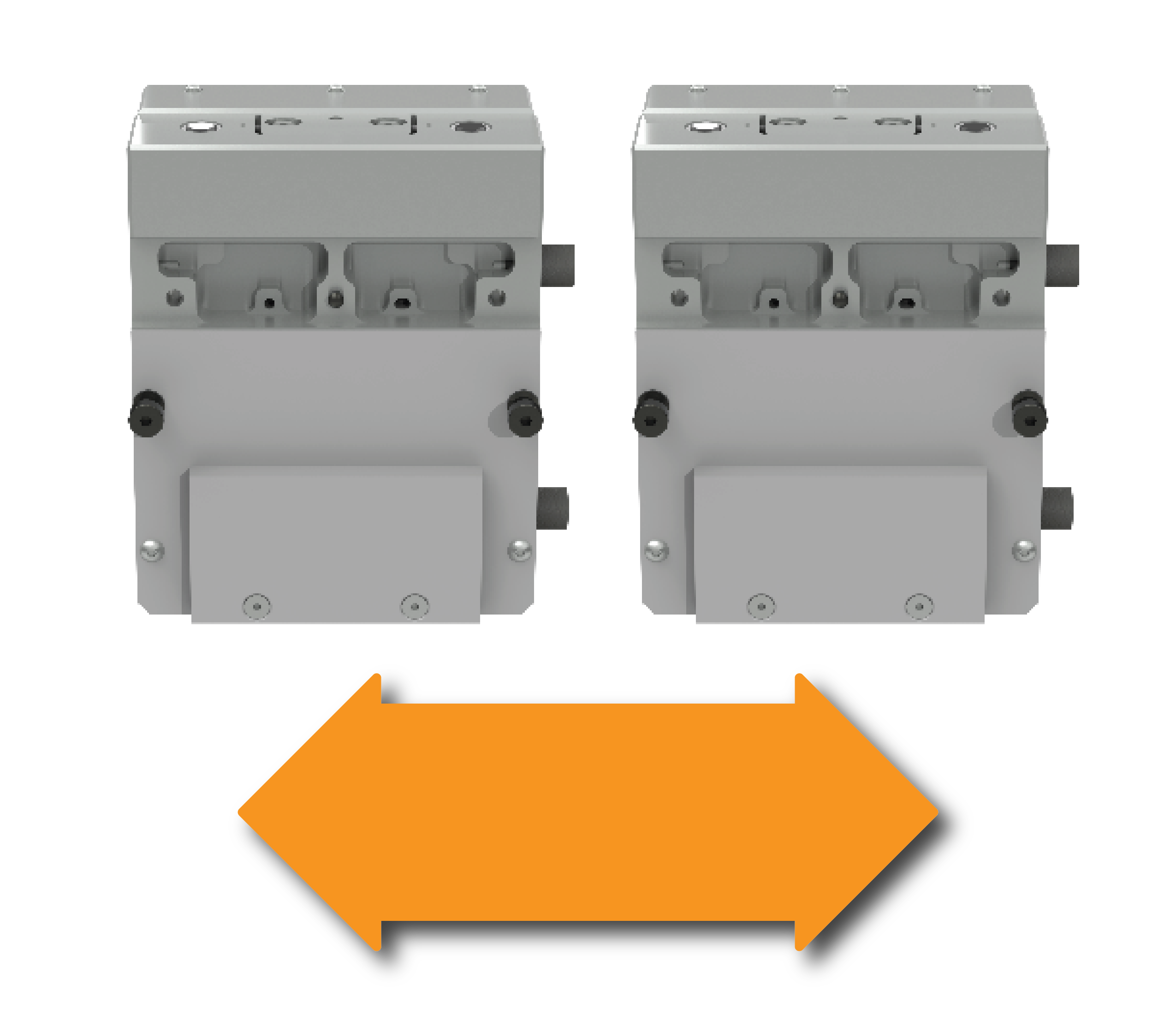

Multiple Configuration Options.

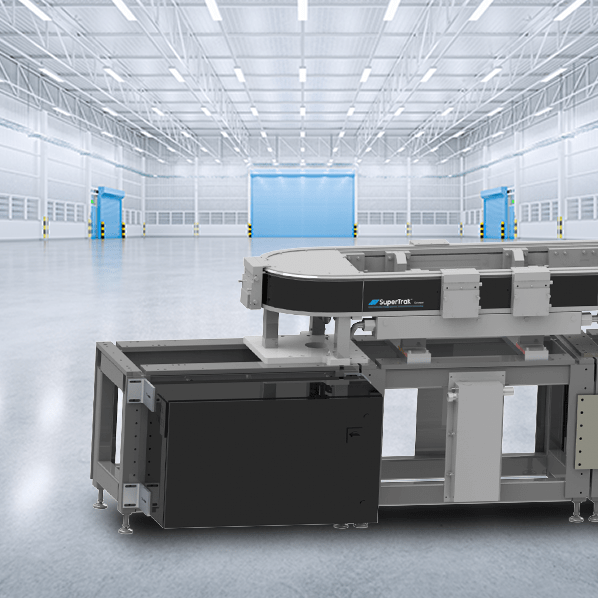

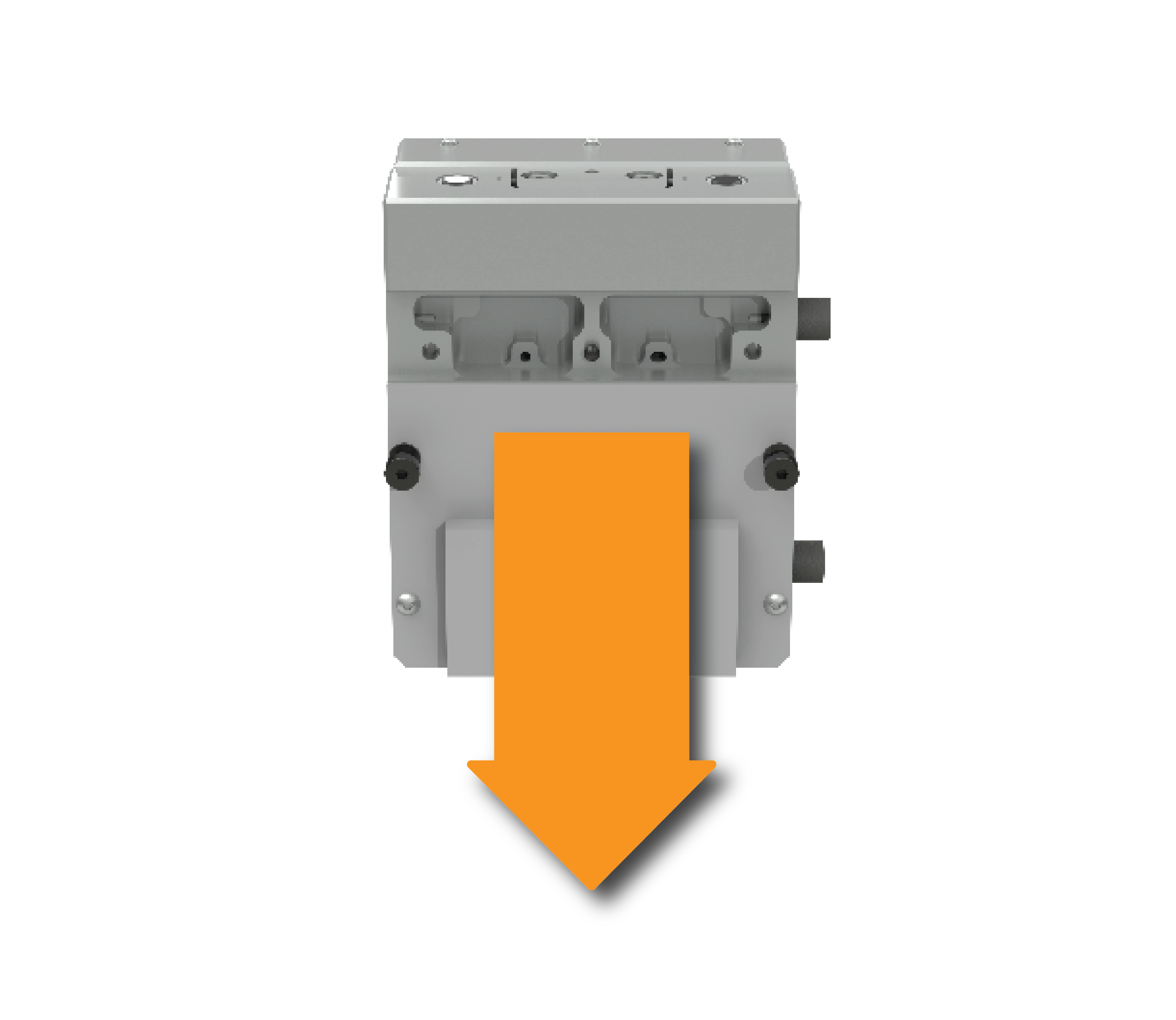

Reduced floorspace, cycle times, and buffer zones are just a few reasons SuperTrak CONVEYANCE™ is attractive to machine builders and automation integrators. With multiple SuperTrak CONVEYANCE™ configurations available and simulations to support the design phase, machine builders can configure a system that works within their parameters without opting for a fully custom conveyance solution.

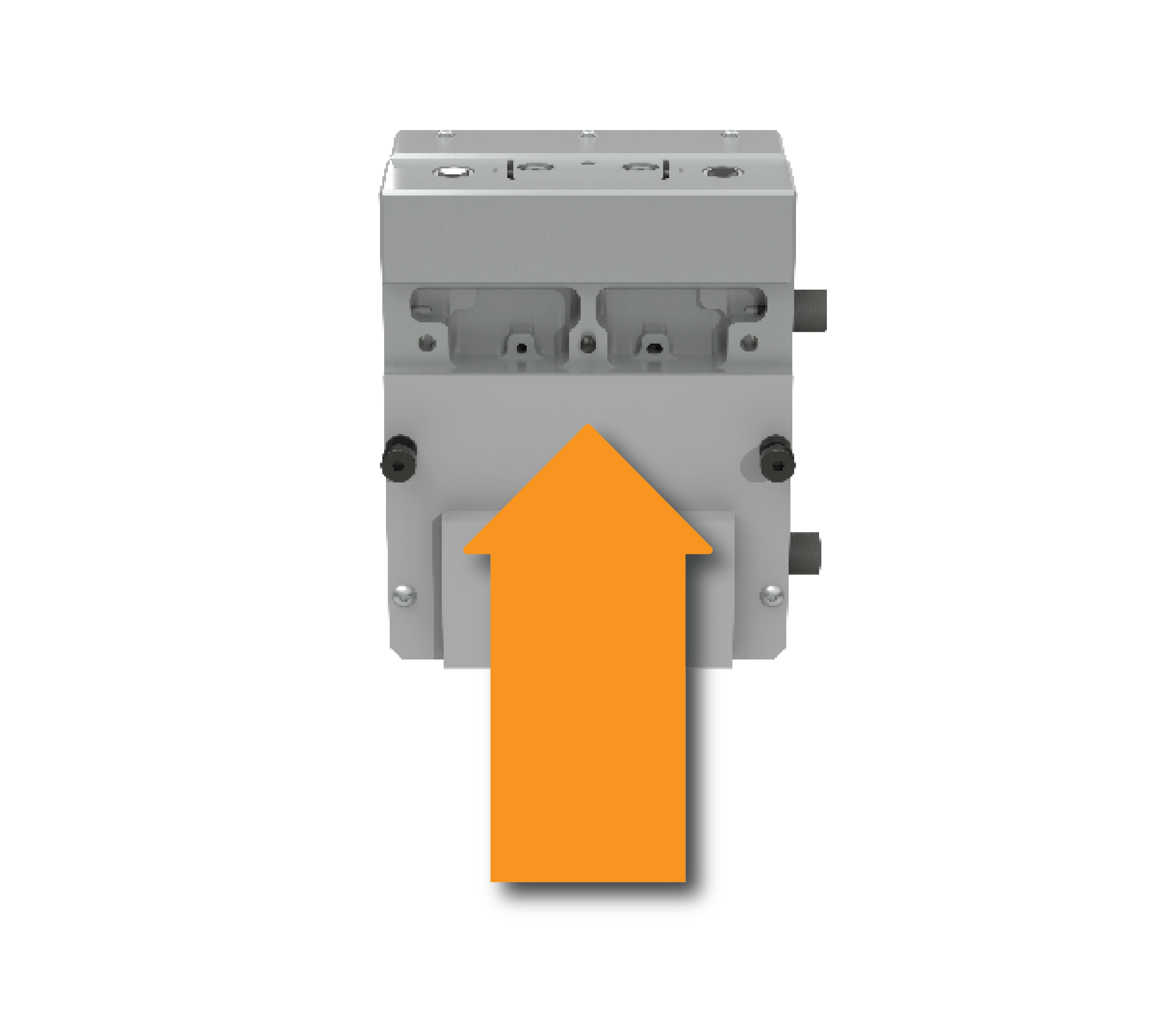

Seamless Installation

Before any SuperTrak CONVEYANCE™ platform leaves our facility, our team of experts thoroughly tests it using the exact configuration created with the machine builders throughout the design phase. Systems are shipped as one complete system, when possible, but when it isn’t, we provide detailed manuals, videos, and training to help support a seamless installation process.

Our primary focus is Smart Conveyance, and our team of engineers and machine builders understand the challenges associated with automation design and implementation. We are committed to supporting our customers every step of the way, whether through e-learning, guided videos, or hands-on in-person support.

Download SuperTrak HORIZON10™ Design Package

Start designing your system with SuperTrak CONVEYANCE™ to discover the benefits of Smart Conveyance.

By thinking of your conveyance early in the design phase, you can fundamentally change the way you build your system, reducing complexities and creating high-performance automation with less risk.