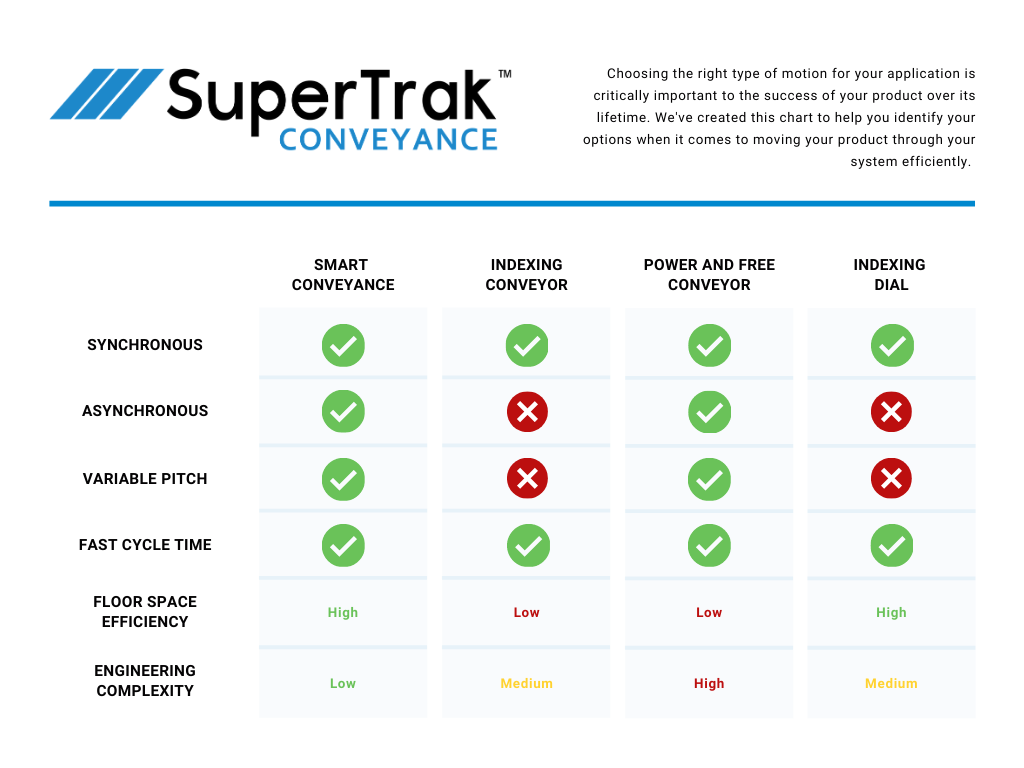

When deciding what type of conveyance system will best suit your needs, you must have a clear understanding of what types of conveyance are available.

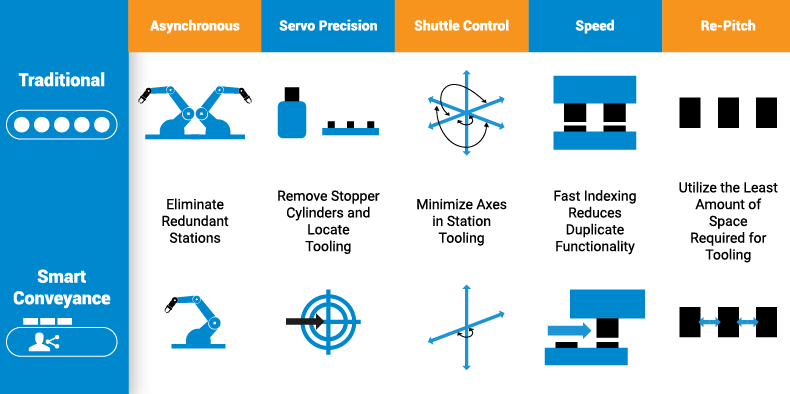

Conveyance is motion – it is how you get a part from point A to point B. Most traditional forms of conveyance are passive, meaning, they simply move parts from station to station. With Smart Conveyance, your motion is active. This means it impacts the process itself. For example, independent shuttle control enables asynchronous motion, allowing you to utilize the conveyance as an axis of motion in the process.

Your conveyance platform is the foundation for your automation cell. This platform impacts your system performance and has a significant influence on your station design.

To gain a better understanding of the differences between traditional and Smart Conveyance, let us review how each impacts motion, footprint, process, OEE, and data.

Traditional Conveyance

Many forms of traditional conveyance such as – indexing conveyors or indexing dials are commonly synchronous, meaning each station operates at the same time in the same way. There is no flexibility; every step in the process has only one option and process time is dependent on your longest station. With traditional conveyance, you are moving a product or piece from station to station, and for simple processes, this format may be all that’s needed.

Motion:

As mentioned above, traditional conveyors have limited motion capabilities; each shuttle moves together at the same time, in the same way, repeatedly. Every step in the process has only one option. These kinds of systems can be effective for manufacturing operations that require lower volumes or simple operations.

Footprint:

Traditional conveyors such as indexing conveyors and power–and–free conveyors can be limiting when there is a defined amount of floor space available. However, an indexing dial or rotary table may be beneficial when you have limited space on your factory floor because they can be compact. A rotary table can fit many part nests and place your tooling around the outer edge. Taking up a smaller footprint in comparison to linear systems.

Process:

A cell with two stations could potentially benefit from the motion available in Smart Conveyance in order to simplify tooling requirements. However, this benefit would be outweighed by the premium cost of typical Smart Conveyance platforms.

If you need your process stations to move parts at different speeds, many traditional conveyance only provide synchronous motion – meaning each part can only move as fast as your slowest station. This usually isn’t ideal when you are looking to decrease cycle times and increase throughput.

OEE:

OEE (overall equipment effectiveness) measures how well a system is performing when it’s in production. OEE is measured by multiplying throughput, product quality, and system availability. Since traditional conveyance usually has more moving parts, regular maintenance is required which can lead to an increase in downtime, causing a reduction in throughput, and thus negatively impacting OEE.

Data:

The data that you are able to derive from most traditional types of conveyance is limited and doesn’t play a large role in enhancing the performance of your automation.

Smart Conveyance

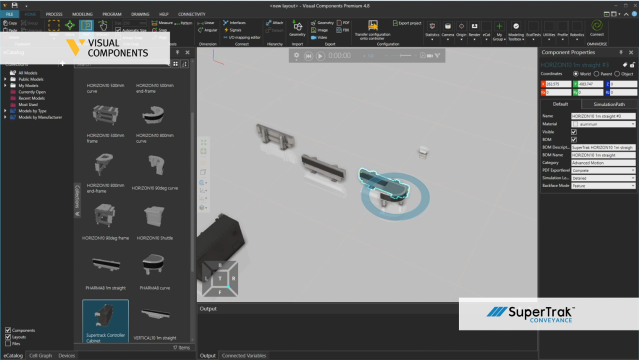

Smart Conveyance combines the elements of automation conveyance with the capabilities of advanced digital technologies to enable diagnostics, performance optimization, and an intelligent user interface.

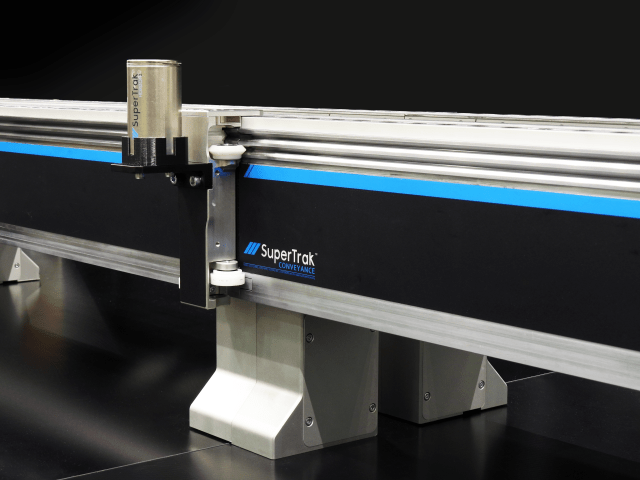

A Smart Conveyance platform like SuperTrak GEN3™ offers three major advantages over a traditional conveyor system – higher speeds, more precision, and independent shuttle control.

Motion:

Smart Conveyance offers active motion; it impacts the process itself. An example of this would be the ability to independently change the velocity and acceleration of a shuttle. Smart conveyance platforms like SuperTrak™ use 4G acceleration and allow parts to spend more time in process for increased throughput.

Footprint:

Smart Conveyance helps manufacturers remain competitive by being able to produce more in a smaller amount of space. Due to the amount of integrated functionality in the track, redundant stations, tooling, and stopper cylinders can often be removed, shrinking the overall size of your automation.

Process:

Conveyance is the process (station) connector. It defines the system flow and directly affects the simplicity/complexity of process changes.

With Smart Conveyance, typically a system with six or more stations is an ideal fit. It provides significant value as the complexity of the system increases because there are many advantages of independent shuttle control to enable asynchronous motion, allowing the flexibility to move between 1up and multi-up.

OEE:

Motion and your choice of conveyance platform have a huge impact on your Overall Equipment Effectiveness (OEE). Your platform affects the availability of your technology, the quality you’re able to achieve, and the level of manufacturing efficiency that meets your business goals.

You want your machinery to be available when you need it. Downtime and unplanned maintenance can cause costly delays in production, impacting your production efficiency and bottom line.

With SuperTrak CONVEYANCE™ and TrakMaster™ software, diagnostic tools provide insight into system status and operation so that availability is maximized as is recovery from any unexpected downtime events.

Smart conveyance is fast and precise, so parts spend less time in motion and more time in process. The utilization of smart conveyance features and functionality also allows the optimization of station designs and cycle times to achieve higher performance levels. When you increase your performance, you increase manufacturing efficiency.

Data:

Smart conveyance can also act as a data conduit because it connects all the processes in a system. Tracking and understanding the history of your product can be the difference between continued waste of defective products and quality, market-ready products. Smart conveyance provides access to system performance metrics, providing insight into cycle times, shuttle exchange times, and general station operation. In this way, it allows a clear understanding and focus for system optimization, empowering you to achieve greater efficiency in manufacturing.

The SuperTrak CONVEYANCE™ platform uses TrakMaster™ software as its user interface to enable better machine interaction. TrakMaster™ diagnostics include:

- Fault description and troubleshooting guide

- Power and thermal monitoring

- Oscilloscope for signal tracking

Once you have a clear understanding of your goals and a type of motion that is right for your needs, it’s time to select a conveyance platform. The importance of thinking about your conveyance early in the design phase of your automation cannot be overstated. Your conveyance touches almost every aspect of your automation and impacts its design and performance more than any other singular piece in your automation cell.

To learn more about Smart Conveyance and to utilize it in your system, download our Engineers Guide to Smart Conveyance.