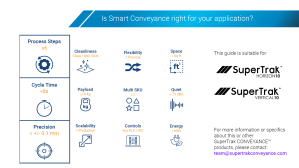

Smart conveyance enables numerous efficiencies in machine development to get to production faster….but is it right for your application? Our Go-No-Go Guide is a good place to start!

From simplifying tooling requirements, to quick system assemblies, to intuitive and easy integrations. Smart Conveyance provides significant value to machine builders and end-users because material costs and engineering hours can be reduced. This offers a solution that balances the overall cost of automation with market demands by allowing for reconfigurability and scalability.

Check out the on-demand webinar to learn more about how smart conveyance can fast track your machine development.

Like any technology, however, smart conveyance isn’t the be-all and end-all that will satisfy all requirements. Certain criteria must be identified accurately at the start of the project in order to realize value.

Let’s look at the major identifiers that highlight the true value of smart conveyance.

Major Identifier #1: Number of process stations

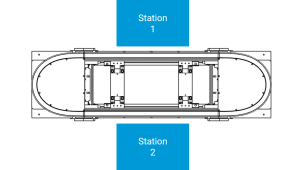

A simple system with two process stations is not the ideal fit for smart conveyance; let me explain why.

A cell with two stations could potentially benefit from the motion available in the smart conveyance in order to simplify tooling requirements, but this benefit would be outweighed by the premium cost of typical smart conveyance platforms.

Simple cell with two stations.

Typically a system with 6 or more stations is the ideal fit for smart conveyance. I’ll talk more about this in a bit.

Major identifier #2: Cycle Time

A slower cycle time of say 15 s, would also not be a suitable application for smart conveyance. One of the main value drivers for smart conveyance is its high-speed capabilities.

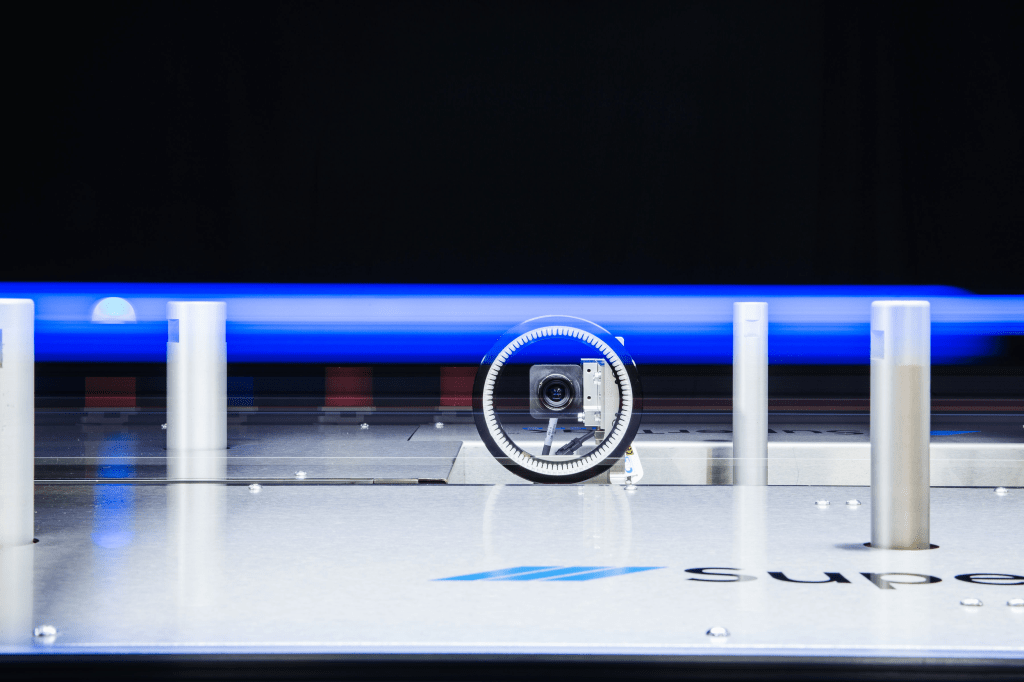

SuperTrak CONVEYANCE™ platforms as an example, index shuttles quickly so one piece of tooling can work on multiple parts rather than one piece of tooling for every part on a shuttle.

A slower cycle time also means that the high-speed capability is not completely utilized.

Major identifier #3: Precision

A precision requirement greater than +/- 0.1 mm means that the application may not require to locate tooling in order to do the work, so it limits the possibility for simplifying tooling requirements and therefore the value for a smart conveyance application.

A simple system with two process stations, a cycle time of 15 s, and a precision requirement greater than +/- 0.1 mm would not realize the value drivers associated with smart conveyance and in my experience would not pass a CapEx proposal.

If we look at a more complex example, however, the value of smart conveyance becomes evident.

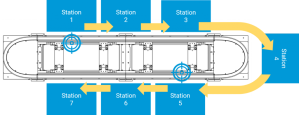

Here we have seven process stations, the cycle time is less than 8s, and the precision required at each station is less than 100 microns.

Now we have an opportunity!

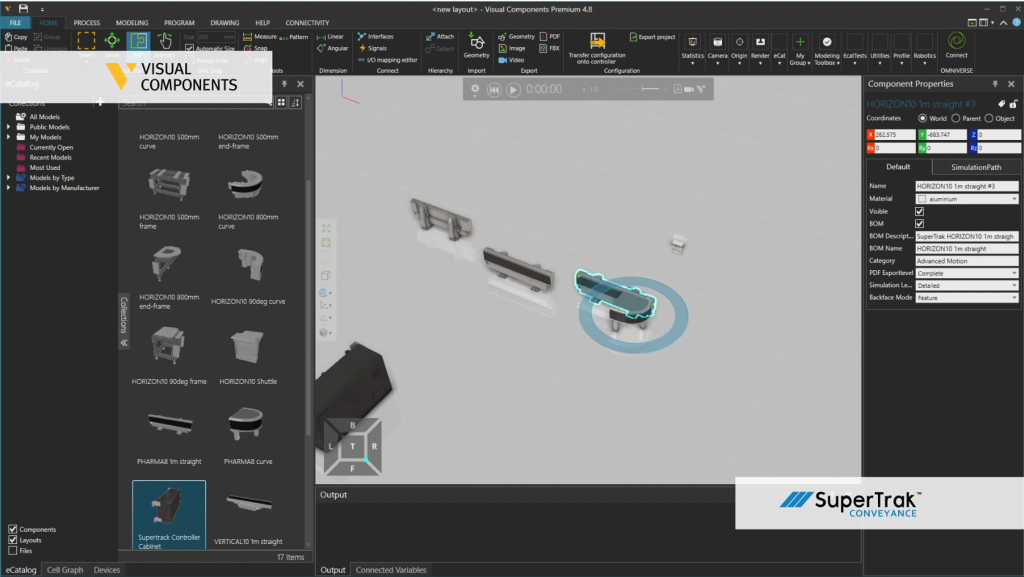

Automation cell with multiple stations.

Smart Conveyance provides significant value as the complexity of the system increases because there are a lot of efficiencies to be gained by taking advantage of the inherent functionality:

- Asynchronous – Implement multi-up capability on slow stations while maintaining single-up on faster stations, removing redundant tooling.

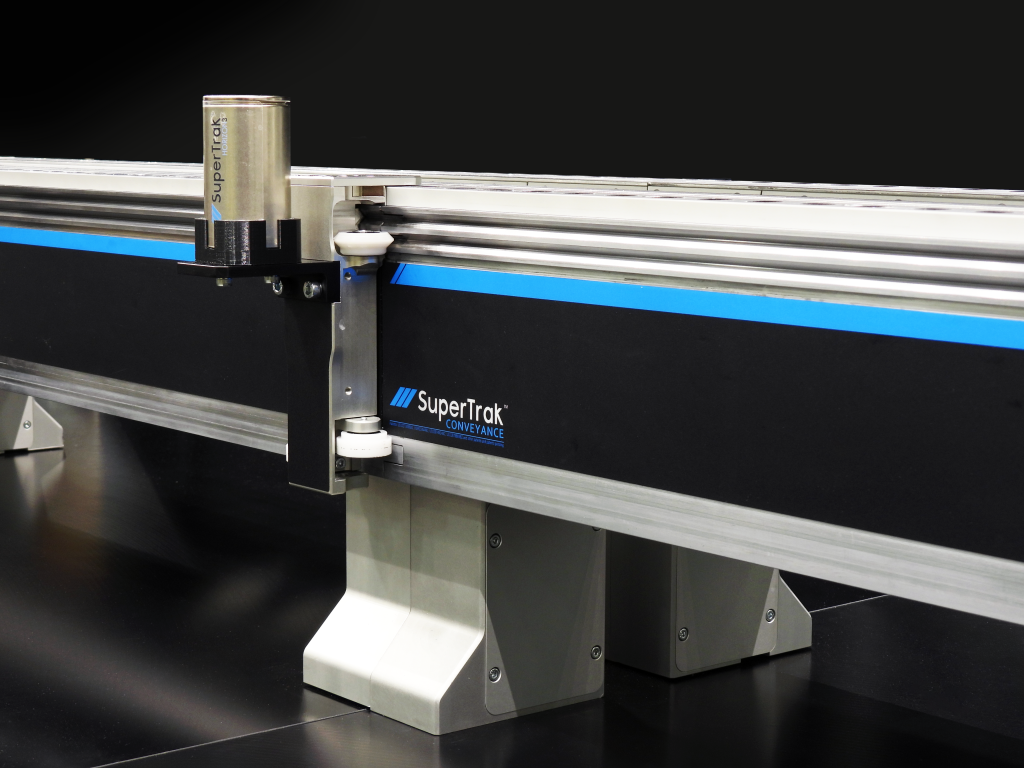

- Servo Precision – Take advantage of the system’s repeatability (+/-0.01 mm) to remove stopper cylinders and locate tooling.

- Independent Shuttle Control – Utilize the motion available in the conveyance instead of adding actuators, sensors, I/O, and programming to station tooling.

- High Speed – Index shuttles quickly so one piece of tooling can work on multiple parts rather than one piece of tooling for every part on a shuttle.

- Re-Pitch – maximize functionality in the minimum amount of space. Set shuttle pitch based on the tooling requirements and re-pitch as necessary.

The upfront cost of smart conveyance is definitely higher than other forms of conveyance platforms, but the value introduced by utilizing the functionality can lower the overall costs by simplifying tooling requirements, saving engineering time, and reducing integration complexity.

Let me explain how.

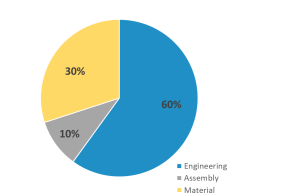

The cost to develop automation is generally broken down as follows:

As you can see, material costs are only 30% of the overall cost.

The engineering is the highest cost, yet reducing it is usually a second priority to the material cost.

With smart conveyance, the cost of your conveyance goes up, but the cost of tooling can come down. Combine that with less engineering time and you would most likely reach an overall cost that is fairly similar to a system with traditional conveyance – but the big differentiator is that the system that implements smart conveyance has better performance, the ability to reconfigure, and can be scaled if production requirements change. You can check out part 2 of my FastTrak webinar series, to learn more on how to FastTrak Automation ROI with Smart Conveyance.

download your official go/no-go guide here! As a rule of thumb, if your application has at least 2 major identifiers in combination with 2 minor identifiers, smart conveyance could offer you an enhanced ROI for your automation cell.

If you’re looking to improve the ROI of your automation cell and think smart conveyance might be right for you, contact us to create a custom simulation for your team.