As a manufacturer in the life sciences space, you deal with a lot of uncertainties that can impact how you choose to develop your automation.

During the product development phase, requirements often change, during the scaling-up phase, you must adapt to changing market conditions and may be required to alter your processes or throughput.

While these changes may be unavoidable, one thing remains certain, the life sciences market is very dynamic and requires reliable, high-speed, and adaptable automation that keeps up with product demand without compromising on quality.

The decision to invest in capital equipment is complex. Unclear strategic directions, shifting priorities, staffing challenges, and inconsistencies in operation all contribute to risk elements you must consider when building and designing your automation. You want to select equipment that your team is confident in and that allows you to build automation to help you meet your business demands and improve efficiencies.

If you are assembling medical devices or diagnostic products, our life science customers rely on our expertise to help them reduce their risks and develop the automation solution that is right for them. With life science manufacturing, solutions are needed to solve complex automation assembly challenges that are typically characterized by tight tolerances, no-touch zone, the need for low particulate generation, and superior quality control.

Your choice in conveyance shouldn’t be an afterthought

When working with some of the world’s largest manufacturers we’ve noticed a trend where the choice in conveyance isn’t top of mind and is often a detail looked at later in the development process. But it shouldn’t be.

Whether your top priority is being able to quickly design and deploy your automation or having the flexibility to increase throughput without investing in more capital equipment, your choice in conveyance plays a major role and shouldn’t be taken lightly. Your conveyance platform touches every piece of your automation and therefore naturally impacts all the major pieces of your strategy – your people, process, and infrastructure.

Now that we’ve convinced you that your conveyance platform shouldn’t be an afterthought, (or if we haven’t, we talk more about how conveyance can impact your growth strategy in our webinar “Is Conveyance Gating Your Growth.”) how can you determine what conveyance platform will help you best meet your business goals?

To answer this question, we turned to our team of application engineers.

With a combined 45 years of experience interfacing with customers and creating inventive solutions to their unique needs, they’ve pretty much seen and been asked everything.

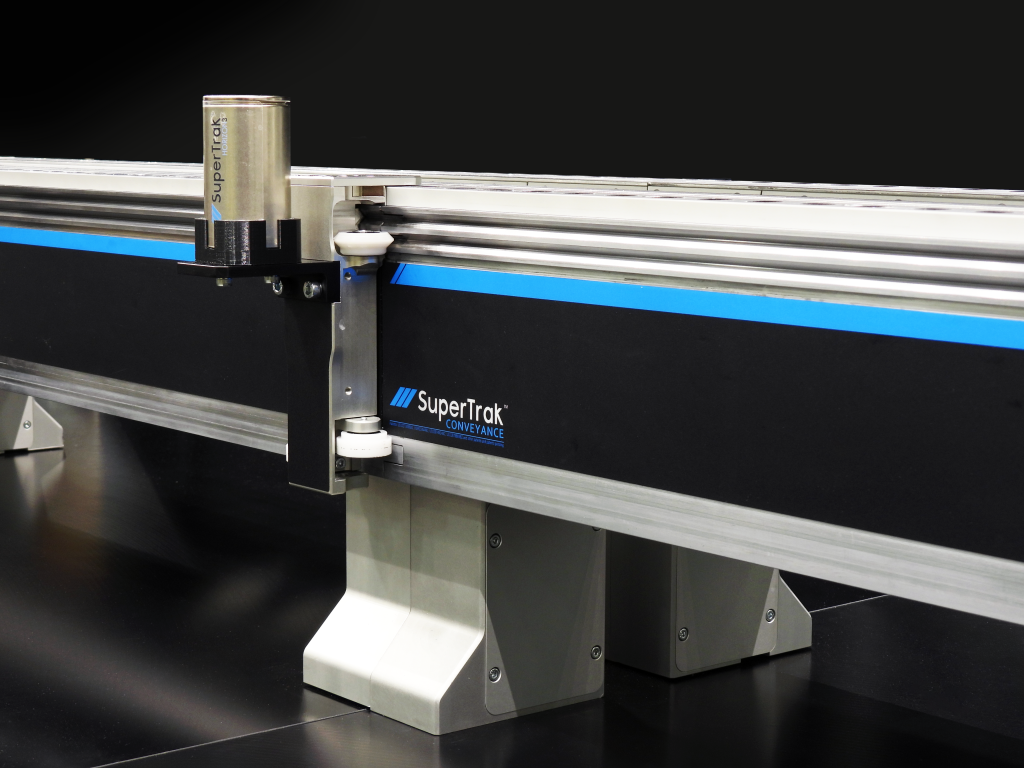

Looking specifically at the life science industry, we challenged them to tell us why the SuperTrak CONVEYANCE™ platform is the ideal foundation for many world-leading automation processes.

Here’s what they had to say:

Life science manufacturers can typically be defined as having the need to produce low–cost parts at a high volume. With this in mind, we’ve outlined 8 main areas of focus where the SuperTrak CONVEYANCE™ platform can help life science manufacturers meet their goals.

8 ways SuperTrak CONVEYANCE™ can help life science manufacturers.

1. Operational efficiencies

Not unlike other manufactures, life science manufacturers are concerned with OEE. OEE is the resulting product of Machine Availability X Machine Performance X Machine Yield. There are many ways that the SuperTrak CONVEYANCE™ platform can help. For example:

Machine Availability

- Low preventative maintenance requirements

- Low MTTR and high MTBF

Machine Performance

- Low pallet exchange times ensuring that process stations are sitting idle for the least amount of time possible between parts.

- High velocity and acceleration to reduce time to travel longer distances.

Machine Yield

- Smooth and precise movement and positioning ensure that the transport system does not contribute to bad part creation.

2. Improved production yields

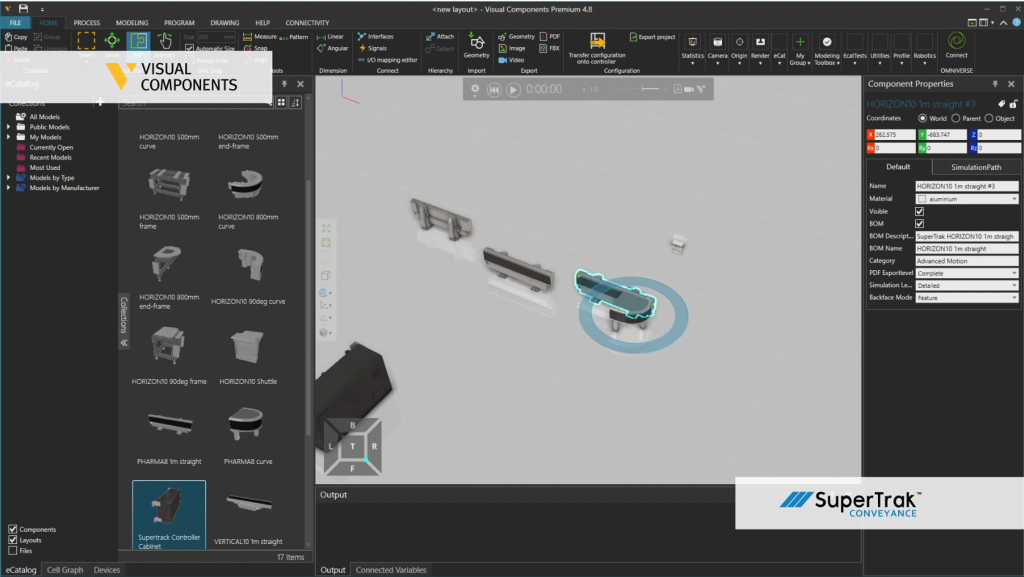

With the current global pandemic, many life science manufacturers are seeing increased demand for their products. The ability to scale effectively is essential for effective execution. SuperTrak enables scaling because of independent shuttle control, which allows the reconfigurability of targets, velocities, accelerations, and routing. This means that stations can be added or optimized to meet output capacity expectations.

3. Adaptable and expandable to meet changing needs

Having flexible automation that you can develop as you go is critically important, especially to life science manufacturers who need to comply with FDA regulations. During the development phase, we often seem more manual processes being used while IP’s are being developed or regulatory processes are completed. As validations are completed, there is now a need for semi-automated production, and manual stations are now integrated into an autonomous system to demonstrate cycle time capability. Once you are in the ramp stage with lower volume production all manual stations can be converted to a fully automated system. Finally, as the market demands higher volumes, you can utilize asynchronous transportation to duplicate systems and for high-speed, high-volume production.

4. Long life with low maintenance

When producing high–volume products, having maximum availability of your automation is key. Minimal moving parts on the SuperTrak CONVEYANCE™ platform requires a simple preventative maintenance schedule and reduced downtime and minimal moving parts. For example, the only moving parts are the wheels (X4) on the pallets that have a typical lifespan of up to 50,000km.

5. Gentle product handling

Many life science products are fragile or poorly contained at some stage during production.

The SuperTrak CONVEYANCE™ platform includes precisely controlled servo positioning that eliminates the need for hard stops, and the built-in collision avoidance ensures no shuttle to shuttle contact which means that there are no large g-forces applied to the product. In addition, as each shuttle’s motion is fully configurable, it is possible to have reduced accelerations and/or velocities at processes that require even lower jerk.

6. Clean operation

The majority of life science applications require some level of cleanliness. The SuperTrak CONVEYANCE™ platform complies with the requirements of cleanrooms Class 1,000 (ISO-6).

7. Quiet operation

Life science products are often manufactured in cleanroom and lab environments where technicians are required to be at workstations in close proximity. It is important that the room is conducive to long to term noise exposure and allows for a level of communication and concentration amongst workers.

The SuperTrak CONVEYANCE™ system allows for quiet operation by:

- Having very few moving parts. Each shuttle has 4 plastic rollers/wheels that provide low friction and a dampened rolling sound as they ride on the steel rail system.

- The built-in collision avoidance ensures no shuttle to shuttle contact or banging noise.

- There are no mechanical stop mechanisms required to precisely stop and locate a shuttle at a process station

8. Reduced floor space

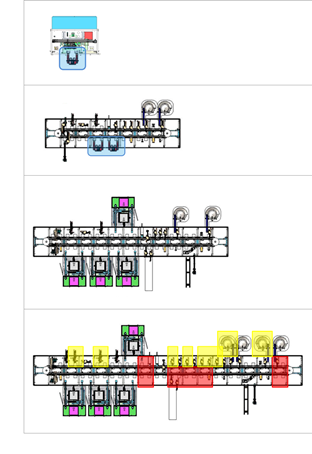

In manufacturing, floor space is at a premium. As market demand increases, adding space for accommodating more capital equipment may not be an option. With the SuperTrak CONVEYANCE™ platform, there are built-in mechanical as well as software features that enable a smaller system size.

Mechanical feature examples include:

- The inside portion of the conveyor loop is accessible and usable for the mounting of process stations. This means that some equipment may be mounted within the footprint of the conveyor itself rather than surrounding the conveyor. To facilitate mounting inside the track space, the track stands come complete with mounting features for tooling plates and the track structure includes integrated standard t-slots.

- Corner sections are fully usable for process stations. On many transport systems, the area where shuttles change direction is unusable, but on the SuperTrak CONVEYANCE™, this area provides smooth and precise motion reducing the need to extend the straight portion of the track.

Software feature examples include:

- Asynchronous shuttle motion allows for variable station process times and unique shuttle indexing distances which results in significant flexibility and the ability to maximize station utilization.

- For example, due to the size of the product being manufactured, it may be desirable to have 2 parts on a shuttle. In this case, due to differing process times, it may be beneficial to work on both parts at one time at one process, and at another station, work on 1 part, index the shuttle, and then work on the second part. This reduces the need to double up the tooling in the second process.

- In some cases, the high-speed shuttle transfer and automatic shuttle queuing have allowed a reduction in the number of parallel stations, resulting in less space consumed.

- Flexible shuttle positioning and routing can facilitate running multiple part types on the same system while maximizing station re-use as opposed to the station or full machine duplication.

Still have questions about SuperTrak CONVEYANCE™ and how it can help you discover efficiencies in your processes? Check out all of our top FAQs here.