In addition to the compact size of SuperTrak HORIZON3™, machine builders can use its independent shuttle control combined with up to 10G acceleration and +/-0.01mm repeatability to reduce repetitive tooling and decrease the system’s overall footprint.

Specifications Data Sheet

Straight Section

1000mm

180° Section

300mm Width

(270mm flat rail to flat rail)

Product Fixture Width

50mm +

Maximum Speed

4 m/s

Acceleration

Up to 10G*

Repeatability

+/- 0.01mm (straight section)

+/- 0.025mm (curved section)

Payload

3 kg per shuttle

_

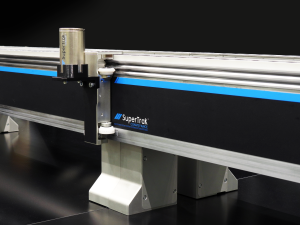

Standard Shuttle Identification

Integrated in track

Process on Curve

Full control

Communication

*More acceleration vs payload information available

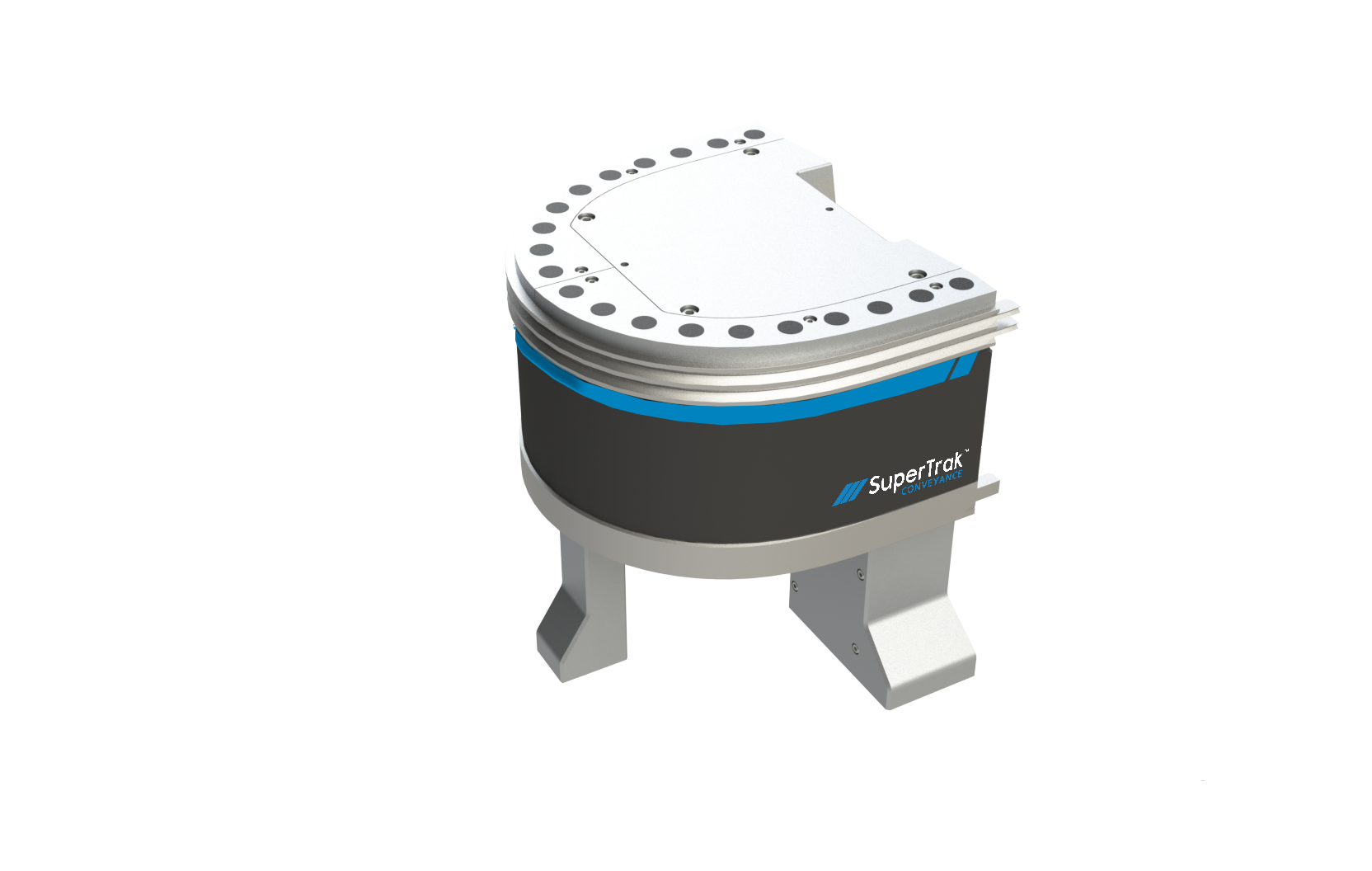

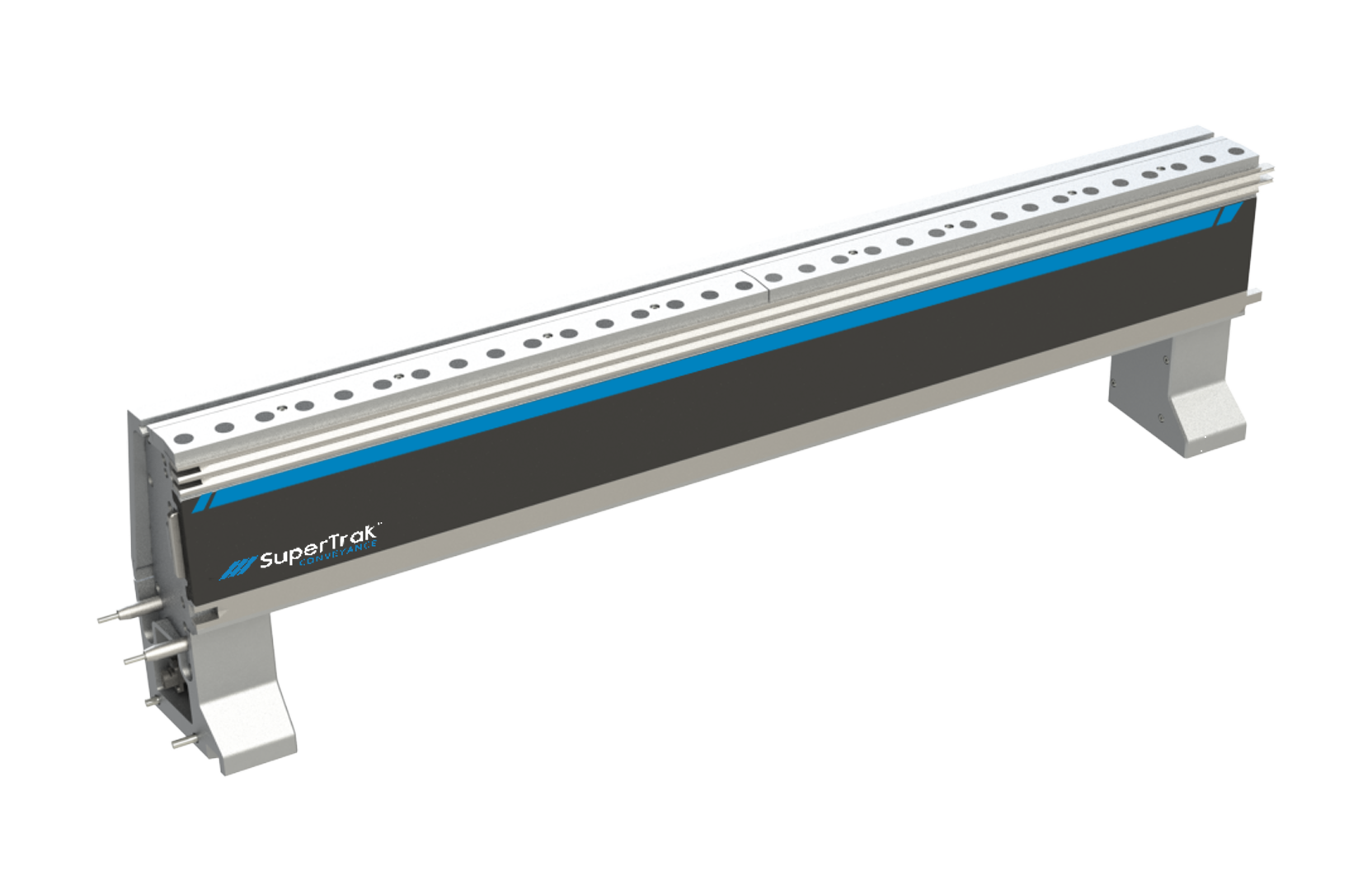

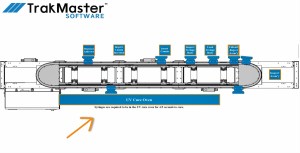

SuperTrak HORIZON3™ Components

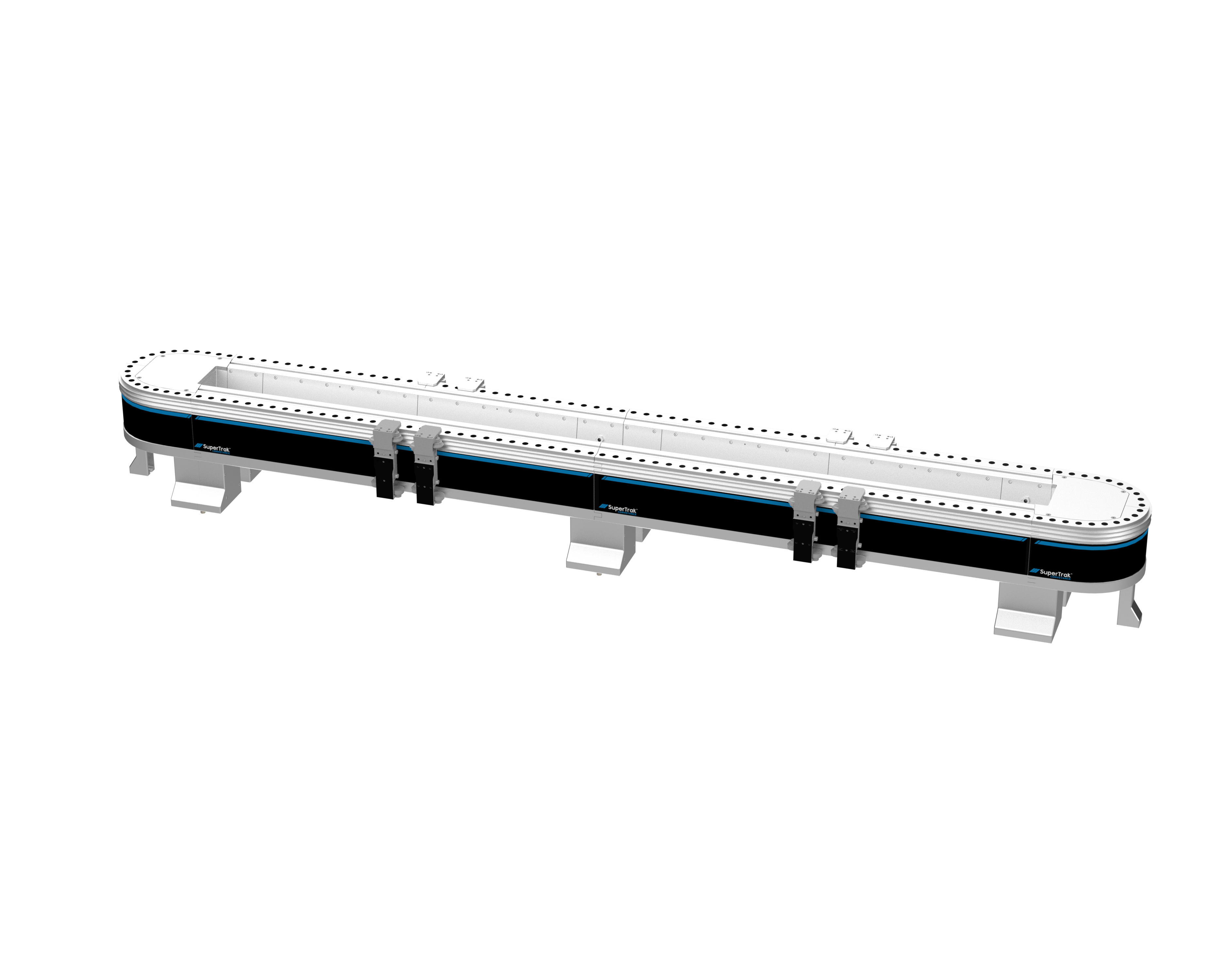

Designed to serve fast, accurate, and compact assembly and packaging applications, SuperTrak HORIZON3™ is available in various system lengths with 300mm wide loops to reduce the size of the track to the maximum.

180° Section (300mm Width) (270mm flat rail to flat rail)

1000mm Straight Section

SuperTrak HORIZON3™ Configurations

300mm Configuration

The 300mm diameter 180-degree curve minimizes the space inside the machine, offering manufacturers options to mount tooling on the outside of the conveyance platform.

Speed – Precision – Independent shuttle control

Increased speeds, lowered settling times, and rapid acceleration improve cycle times and overall productivity.

Increased precision means that stop-and-locate tooling is not required; this results in decreased cycle times with fewer parts and less engineering.

Learn More

Compact Precision for Modern Production Efficiency

Enhancing Lean Manufacturing with the SuperTrak HORIZON3™: Compact Precision for Modern Production Efficiency

Increase Productivity

Spend More Time in Process – Less Time in Motion and improve Manufacturing Efficiency and OEE.

Simplify design & integration.

Use the SuperTrak CONVEYANCE™ integrated functionality to reduce complexity and risks.