The independent shuttle control of SuperTrak HORIZON10™, combined with up to 40m/s² acceleration and +/-0.01mm repeatability, allows machine builders to reduce repetitive tooling and decrease the system’s overall footprint.

Specifications Data Sheet

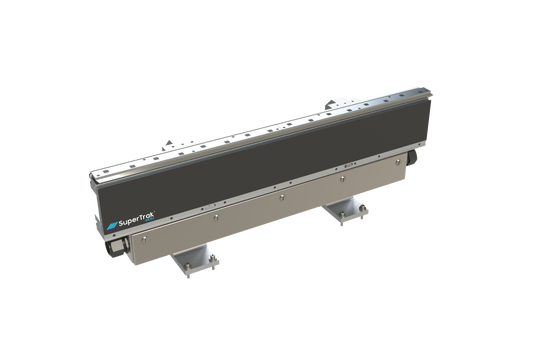

Straight Section

1000mm

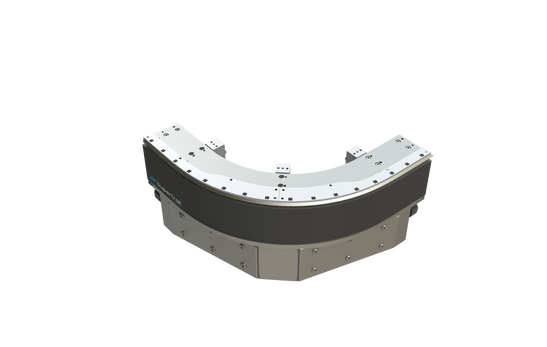

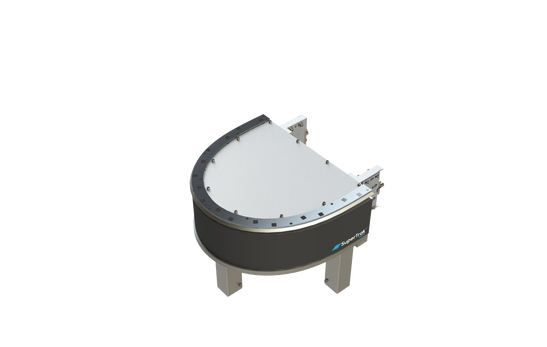

180° Section

500mm Width

800mm Width

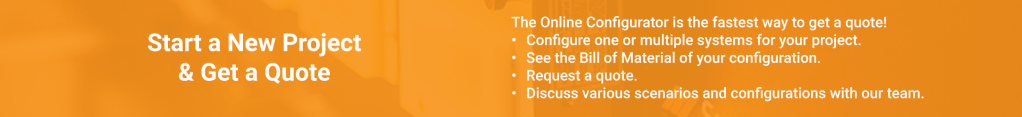

90° Section

1200mm Width (2x 600mm sections)

Product Fixture Width

152 up to 1000mm

Repeatability

+/- 0.01mm (straight section)

+/- 0.025mm (curved section)

Maximum Speed

4 m/s

Acceleration

1G with 10 kg payload

4G with 1 kg payload

Payload

10+ kg per shuttle*

_

Process on Curve

Full control

Shuttle Options

Standard shuttle configuration with 2 or 3 magnet array options

Straight Section

1000mm

180° Section

500mm Width

_

90° Section

N/A

Product Fixture Width

152 up to 1000mm

Repeatability

+/- 0.01mm (straight section)

Not stopping (curved section)

Maximum Speed

4 m/s

Acceleration

1G with 10 kg payload

4G with 1 kg payload

Payload

10+ kg per shuttle*

(max 4kg per shuttle on vertical curves)

Process on Curve

Not possible

Shuttle Options

Standard shuttle configuration with 2 or 3 magnet array options

*Higher payloads possible. Speak to a member of the SuperTrak Team for more info.

Communication

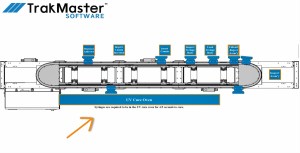

SuperTrak HORIZON10™ Components

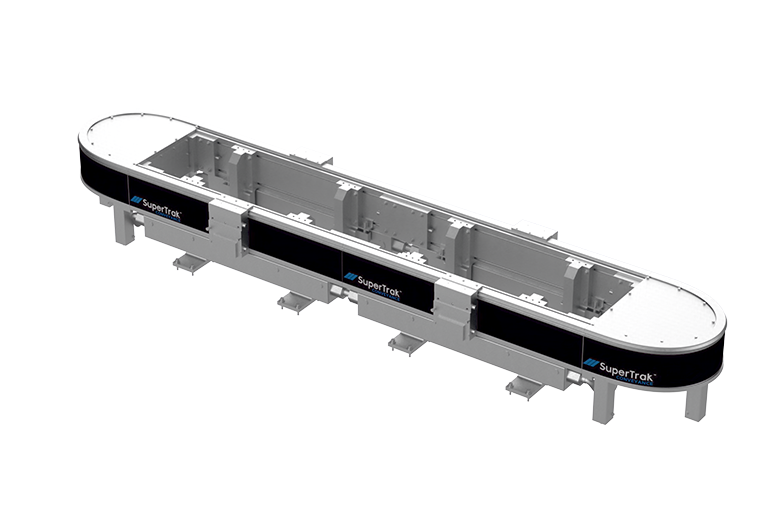

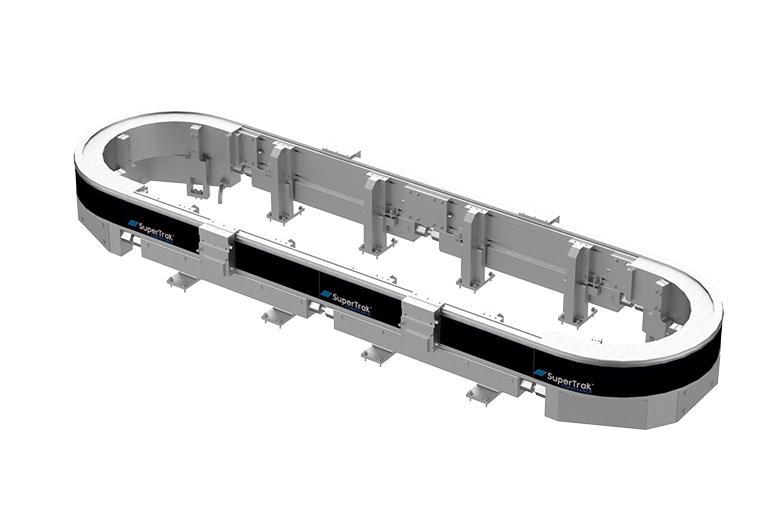

Designed to serve fast, accurate, and scalable assembly applications, SuperTrak HORIZON10™ is available in various system widths and lengths.

- 500mm wide loops reduce the footprint of the track to the maximum.

- 800mm wide loops provide space inside the track to place process stations while leaving better access to the product for operators, feeders, etc…

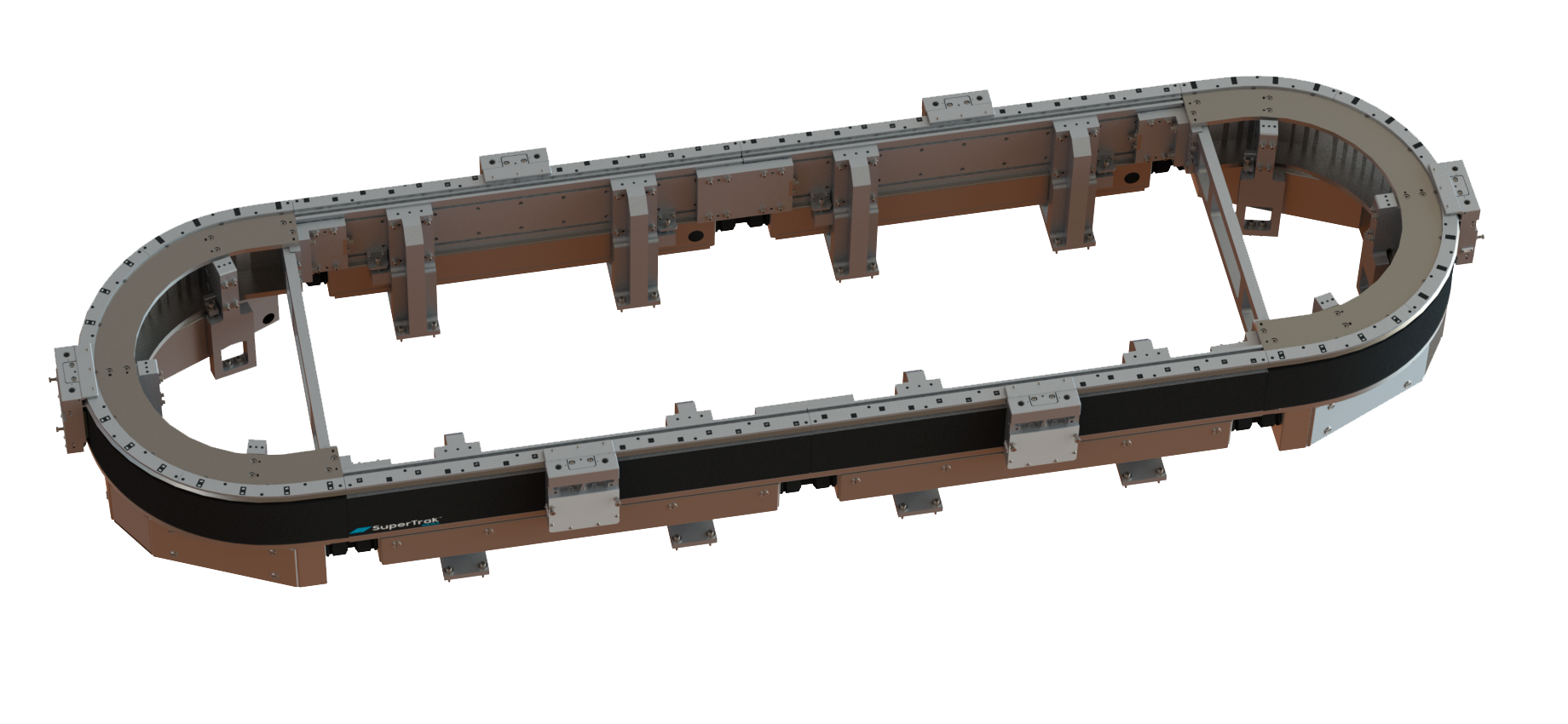

- 90° curved sections allow for extending the space available inside the track.

90° Section 1200mm Width (2x 600mm sections)

180° Section (500mm Diameter)

180° Section (800mm Diameter)

1000mm Straight Section

SuperTrak HORIZON10™ Configurations

500mm Configuration

The 500mm diameter 180-degree curve minimizes the space inside the machine, offering manufacturers options to mount tooling on the outside of the conveyance platform.

800mm Configuration

The 800mm diameter 180-degree curve offers additional space on the inside of the conveyance platform, allowing manufacturers several options to mount tooling on the inside of the machine. This helps minimize the amount of space your factory automation requires on the factory floor.

90° Configuration

The new 90° configuration offers the same floor saving space as a servo or indexing dial. The 90° curved sections allow for even more configuration options such as a squared circle or rectangle. When using this configuration, the system can grow in both length and width. Two 90° sections back to back allow for a system that is 1200mm wide. Manufacturers can fit even more tooling on the inside to minimize system footprint.

Speed – Precision – Independent shuttle control

Increased speeds, lowered settling times, and rapid acceleration improve cycle times and overall productivity.

Increased precision means that stop-and-locate tooling is not required; this results in decreased cycle times with fewer parts and less engineering.

Read More

Increase Productivity

Spend More Time in Process – Less Time in Motion and improve Manufacturing Efficiency and OEE.

Simplify design & integration.

Use the SuperTrak CONVEYANCE™ integrated functionality to reduce complexity and risks.