A recent study stated the top 3 challenges manufacturers are currently facing are:

- Supply chain disruptions

- Labor shortages

- Increasing complexity of equipment

While Smart Conveyance addresses all three of these challenges, this blog will focus on supply chain disruptions and how this is impacting lead times for machine builders and manufacturers.

As a society, we crave instant gratification. We want our online order with next-day delivery options, we want engagement on social media within minutes of posting, and overall, we want real-time rewards. As manufacturers, to be successful, we need to meet these ever-challenging demands for immediacy, and as machine builders, we must provide automation solutions that offer flexibility to meet rapidly changing market demands in a timely manner.

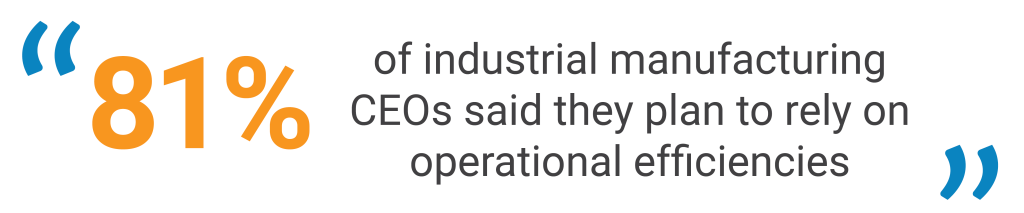

Consumers demand greater product variety and shorter delivery times. This means manufacturers need to implement production lines that are more flexible and closer to customer demand. Implementing this type of process produces a greater variety of products with shorter lead times, allows for smaller batch sizes, and enables more frequent changeovers. Increasingly, the automation and technology that manufacturers use to produce their goods will play a major role in how successfully they will be able to manage continued supply-chain challenges. A 2019 study by PWC found that 81% of industrial manufacturing CEOs said that they plan to rely on operational efficiencies to bolster growth via enhanced competitiveness.

While supply chain challenges are making the implementation of this technology more difficult, there is a bright side; longer lead times can actually improve the ROI of your automation system.

Let me explain…

Faster ROI Realization

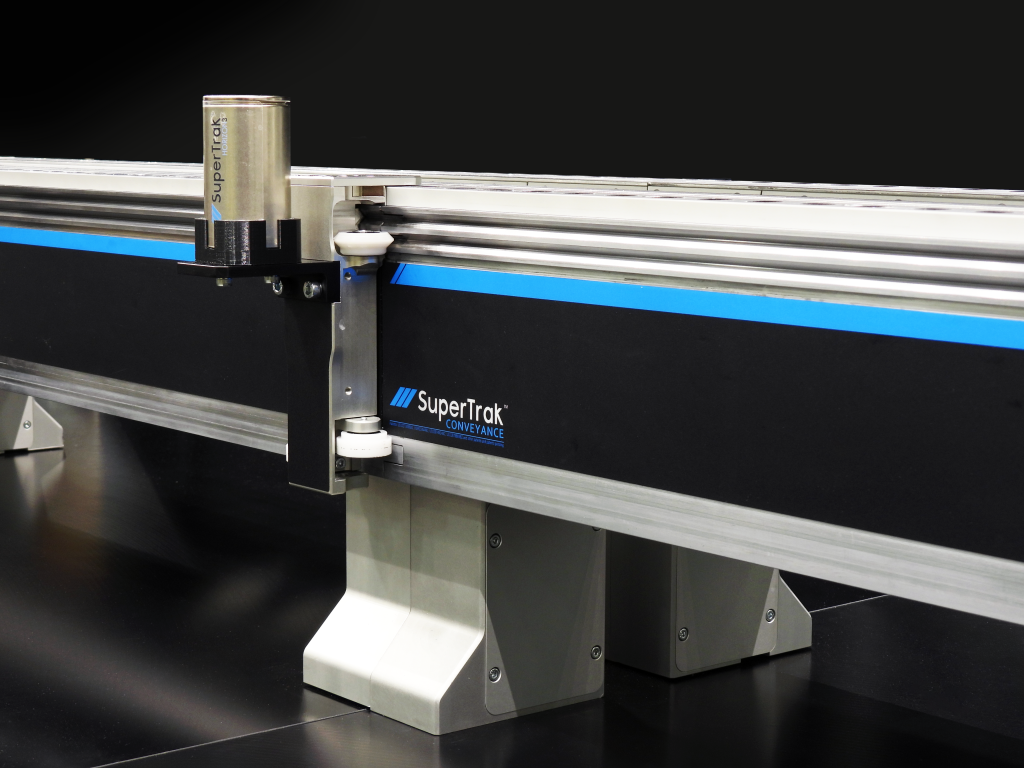

Many machine builders are experiencing staggered availability of parts/systems, often with several months between deliveries. One significant benefit of this supply flow is that funding for new tooling, conveyance solutions, and other system components can be incremental. That means companies aren’t investing in 100% of their automation process years before they start producing a product. As an example, SuperTrak CONVEYANCE™ is currently offering a 16-week lead time, but your robotic arm supplier may only be able to offer a 6-month lead time. Because of these varied lead times, you’re not carrying the cost of the entire system for the full six months. Keeping the current lead time for SuperTrak CONVEYANCE™ in mind, you’re only carrying the combined cost of tooling + conveyance for 16 weeks before you can start assembly and integration.

Get Ahead of Vulnerabilities

Get Ahead of Vulnerabilities

Companies worldwide have scaled back and are trying to do more with less. A study from McKinsey stated that 79% of companies cut costs in response to the global economic crisis. Instead of cutting evenly across the board, it’s important to financially support areas that can contribute to long-term benefits for your company, such as automation. It is also important to get ahead of vulnerabilities through advanced planning and impactful investments.

Planning in Advance

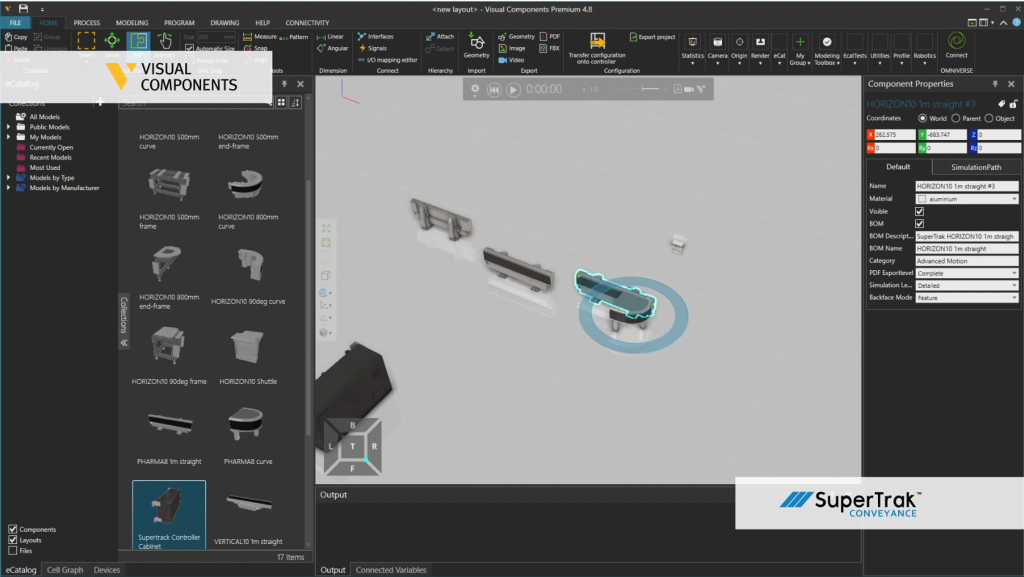

If you’re one of the 85% of designers who doesn’t consider your conveyance platform at the start of the design process, now is the time to change that. Your conveyance acts as the foundation of your automation system and will impact nearly every other component. This allows you to map out system requirements earlier in the design phase and can help your team prepare for longer lead times and provide accurate output estimates to your customers.

As persistent supply chain challenges continue and both machine builders and manufacturers are facing numerous hurdles to meet increasing demand, it’s not all doom and gloom. Consumers are getting tired of waiting months to receive products, which opens the door for manufacturers to fill a gap. Manufacturers can find ways to work better and give themselves the advantage. Realizing faster ROI from automation lines, discovering operational efficiencies, and planning better for potential part shortages in advance should now be the focus.

Impactful Investments

As we mentioned earlier, another positive impact of our 16-week lead time is the opportunity to space out the cost of the system components. This is beneficial for companies because it doesn’t require a large investment all at once, which enables companies to invest funds where they matter most. An article from Bloomberg stated that “average lead time for supplies used for maintenance, repairs, and operations climbed to [a record] of 49 days,” so making impactful investments, specifically those related to preventative maintenance, are critical to your automation process when lead times are so uncertain.

The supply-chain shortage is something companies will continue to struggle with for the foreseeable future. When looking for a Smart Conveyance system for your automation solution, it’s important to go with a trusted source. With lead times as low as 16 weeks, SuperTrak CONVEYANCE™ helps companies succeed in an increasingly competitive space. Contact a SuperTrak team member today if you’re interested in learning more about leveraging our lead time for your next automation process.