The independent shuttle control of SuperTrak VERTICAL10™, combined with up to 40m/s² acceleration and +/-0.01mm repeatability, allows machine builders to reduce repetitive tooling and decrease the system’s overall footprint.

Specifications Data Sheet

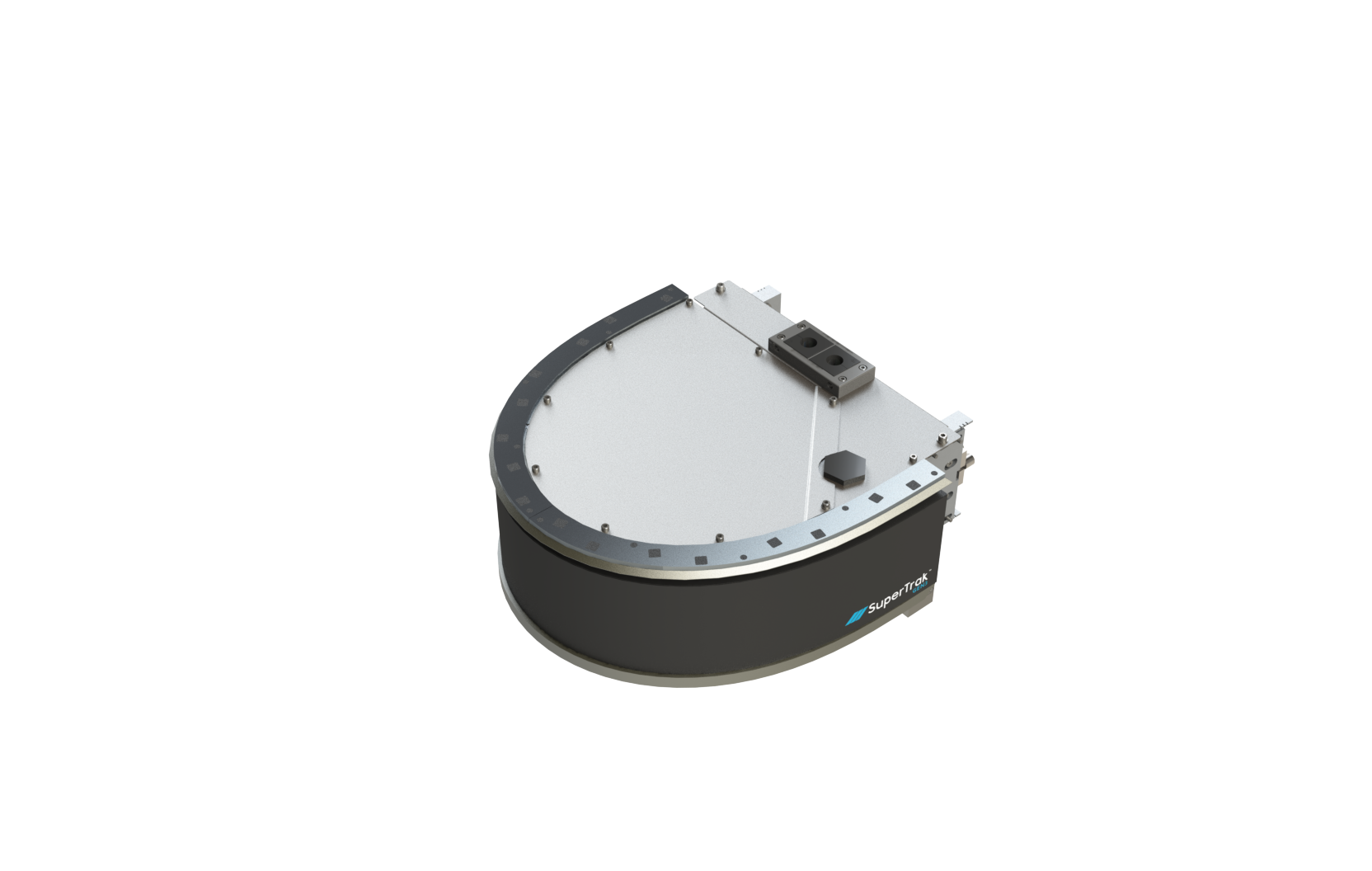

Straight Section

1000mm

180° Section

500mm Width

_

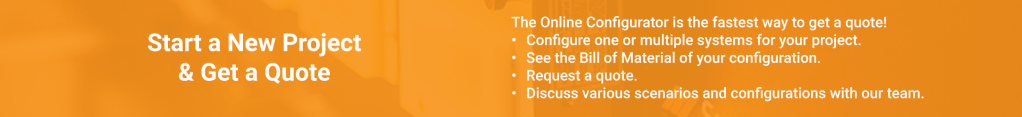

90° Section

N/A

Product Fixture Width

152 up to 1000mm

Repeatability

+/- 0.01mm (straight section)

No process on curve

Maximum Speed

4 m/s

Acceleration

1G with 10 kg payload

4G with 1 kg payload

Payload

10+ kg per shuttle*

(max 4kg per shuttle on vertical curves)

Process on Curve

Not possible

Shuttle Options

Standard shuttle configuration with 2 or 3 magnet array options

Straight Section

1000mm

180° Section

500mm Width

800mm Width

90° Section

1200mm Width (2x 600mm sections)

Product Fixture Width

152 up to 1000mm

Repeatability

+/- 0.01mm (straight section)

+/- 0.025mm (curved section)

Maximum Speed

4 m/s

Acceleration

1G with 10 kg payload

4G with 1 kg payload

Payload

10+ kg per shuttle*

_

Process on Curve

Full control

Shuttle Options

Standard shuttle configuration with 2 or 3 magnet array options

*Higher payloads possible. Speak to a member of the SuperTrak Team for more info.

Communication

SuperTrak VERTICAL10™ Components

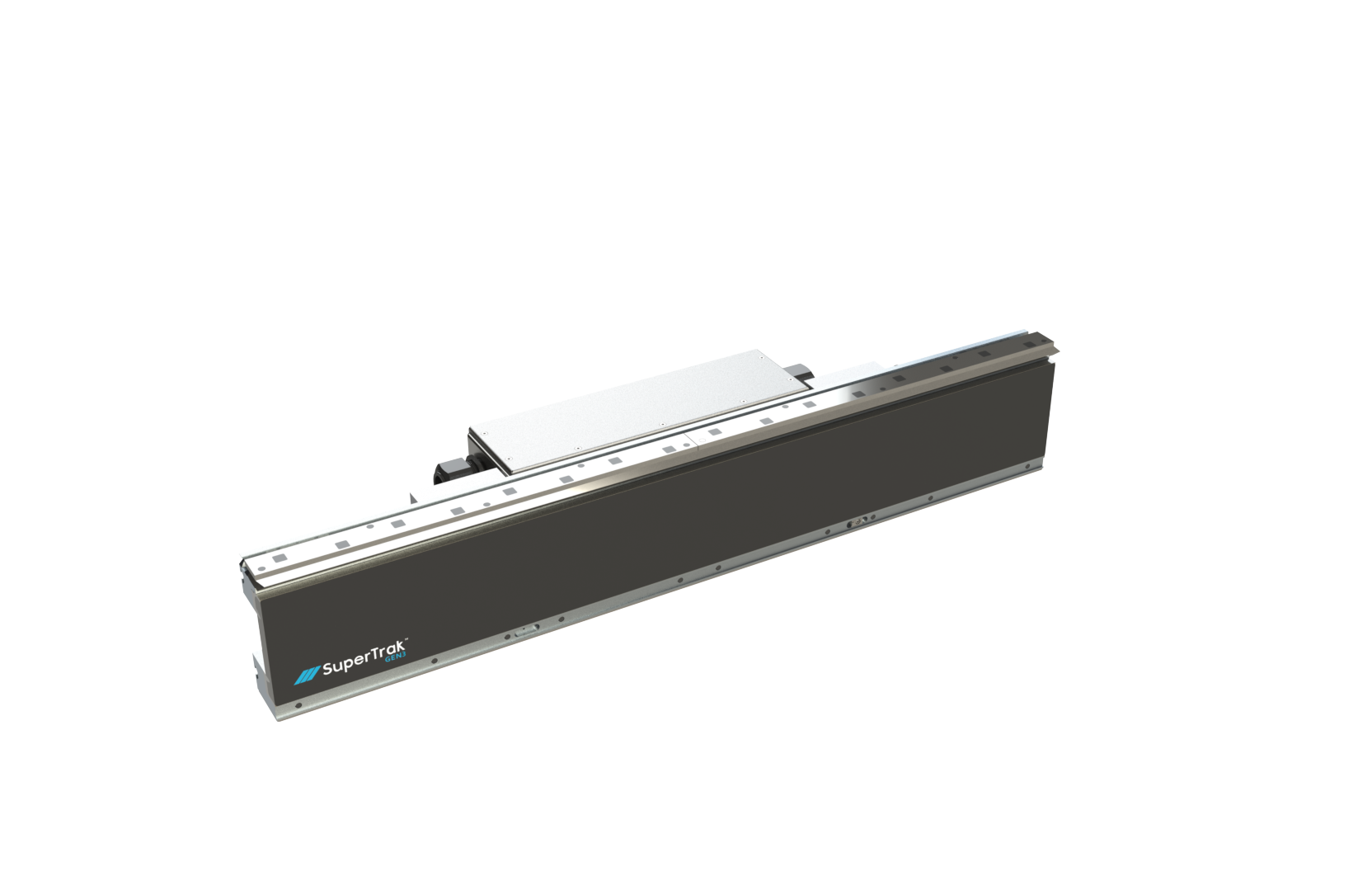

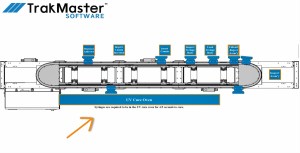

Designed to serve compact, accurate, and flexible assembly automation, SuperTrak VERTICAL10™ is an asynchronous conveyor available in various system lengths, with 500mm wide curves and wall mounts to ease integration.

Low Profile 180° Section (500mm Diameter)

Low Profile Straight Section

SuperTrak VERTICAL10™ Configuration

Vertical

This configuration is best suited for manufacturing processes with a unidirectional part flow application. On curves, it has a slightly lower weight capacity of 4kg per shuttle but maintains the 10kg capacity on straights. Utilized in applications where floor space is at a premium, the vertical configuration has succeeded in automotive battery assembly and packaging applications.

Speed – Precision – Independent shuttle control

Increased speeds, lowered settling times, and rapid acceleration improve cycle times and overall productivity.

Increased precision means that stop-and-locate tooling may not be required; this results in decreased cycle times with fewer parts and less engineering.

Read More

Increased Productivity

Spend More Time in Process – Less Time in Motion and improve Manufacturing Efficiency and OEE.

Simplify design & integration.

Use the SuperTrak CONVEYANCE™ integrated functionality to reduce complexity and risks.