Electrical Devices and Wiring Harnesses

Electrical devices and wire harnesses are present in a wide range of industrial applications, including industrial connectivity, computing, and the automotive sector. Whether a machine is designed to assemble connectors, switches, sockets, electrical sub-components or harnesses, typical processes involve loading parts in the machine, inserting them within an assembly, dispensing and curing glue, labeling/printing/marking, crimping, inspecting/testing, screwing, rejecting and unloading parts, with some other processes such as welding and cutting being common in the field.

Additional Advantages

The main challenge in this type of manufacturing is managing floor space, as production areas are often crowded with operational machines or idle equipment for spare parts. Adjusting production batches daily is also crucial for meeting the varying demands of customers.

Smart Conveyance aims to reduce floor space while increasing flexibility, achieving similar or higher throughput at competitive prices compared to traditional systems. SuperTrak CONVEYANCE™ delivers value by enabling complex motion at each process step, reducing the need for additional tooling and enabling more processes to occur at a single location. With software controlling this motion, carrying or adding multiple products on the same line becomes easier.

Wiring Harness Application

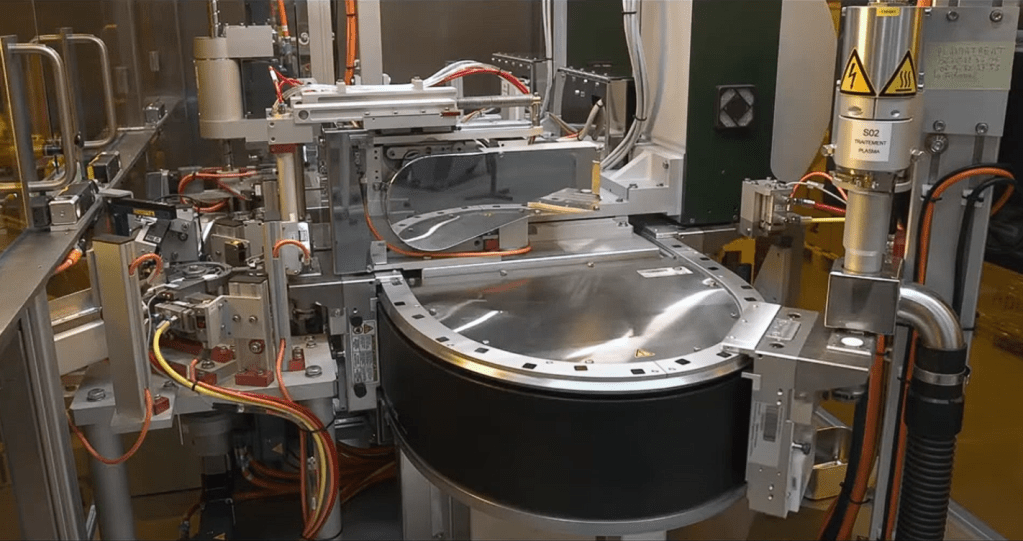

Larisys Industries successfully implemented an assembly machine based on a 4m SuperTrak VERTICAL10™ system for a wiring harness application. The machine’s size is estimated to be half that of a standard conveyance solution, and the line’s accessibility is vastly improved to facilitate maintenance.

“The SuperTrak technology is disruptive because of its speed, precision, compact design and capability to be easily configurable.” – Larisys Group.

SuperTrak CONVEYANCE™ Users Showcase Their Machines in Action:

Customer Highlights – Printing Application:

“The key advantage of this magnetic track system is to convey linearly and very precisely the parts […]. Reliability, repeatability, high-speed transfers are also strong arguments for SuperTrak”

Neyret Group* * SuperTrak HORIZON10™ distributed by B&R™

Customer Highlights – Assembly Processes:

“Assembly processes are typically implemented using shuttle transport systems for workpiece transport, combined with our handling modules. Our goal is to achieve optimal production flow with minimal footprint.”

K&S Anlagenbau GmbH** ** SuperTrak HORIZON10™ distributed by Bosch Rexroth™ under the name ActiveMover™

Get Started with Smart Conveyance

Speak with a SuperTrak CONVEYANCE™ team member today to see how you can unlock your process’s potential by levering higher speed, increased precision, and independent shuttle control.

If you have an upcoming project, now is the time to start thinking about your conveyance system.