How has your market changed over the past year?

Perhaps you are being asked to find more efficiencies with less time and fewer resources? What once worked well may need to be re–examined and reworked. So how do you figure out how to move your business forward? If you are in manufacturing, chances are that you already use the lean methodology. So, when you have eliminated as much waste as possible where is there left to go?

Lean methodologies have worked well over the past century within the manufacturing space, but things are changing quickly.

What is Lean Methodology in Manufacturing?

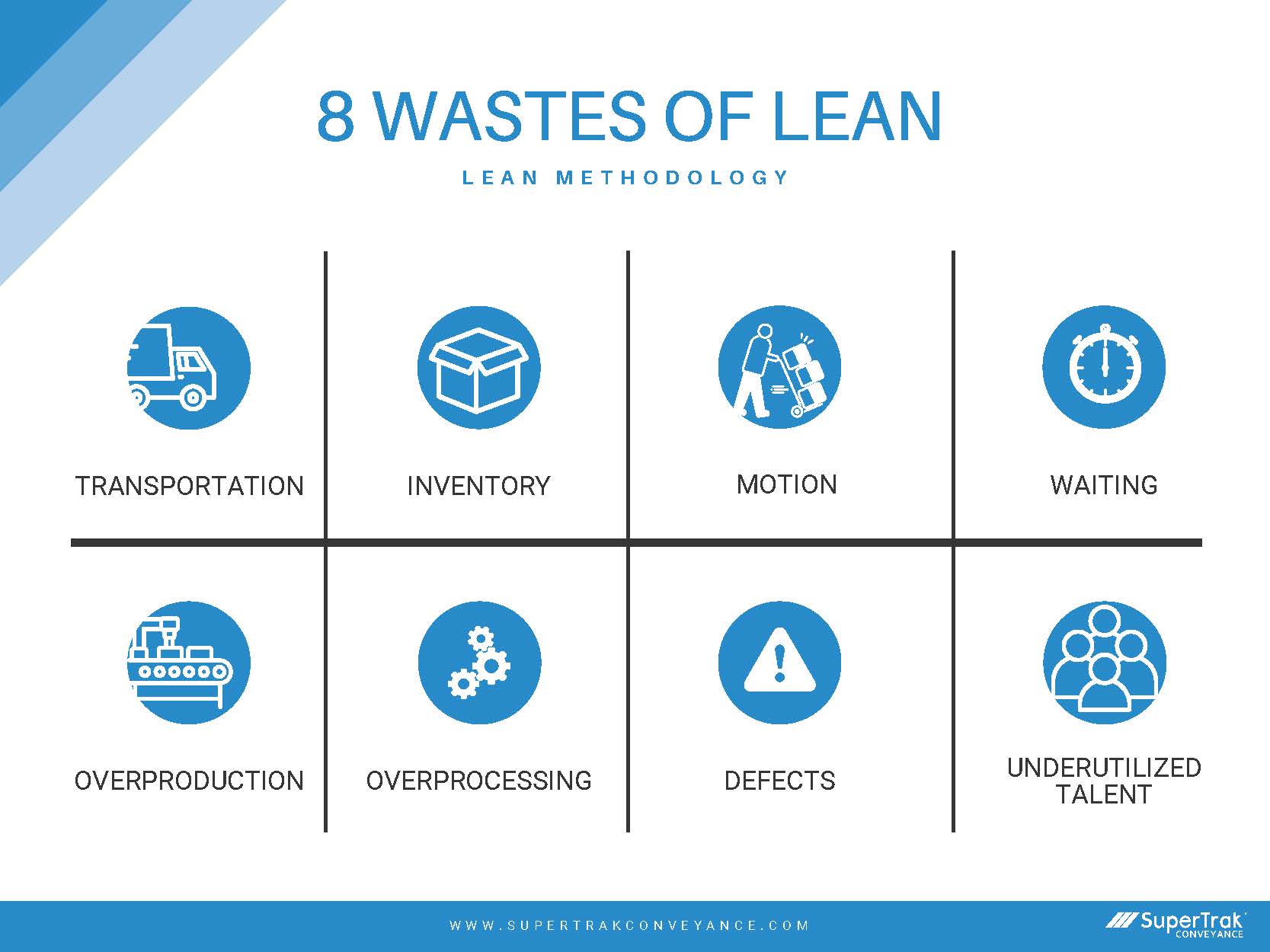

If you are not familiar with lean manufacturing, it is built on the principle of eliminating waste in 8 key areas of the manufacturing business: Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing, Defects, and Underutilized Talent. The focus is on reducing waste so that functions that directly bring customers value are prioritized over those that do not.

This methodology focuses on improving internal processes. Reducing waste internally can certainly reduce your business costs and those savings can be passed along to the customer or reinvested. It has worked well in manufacturing for just about a century and continues to work well for businesses that rely on high volume production with low variability.

Some Advantages of Lean:

- Reduces costs

- Reduces waste

What is Agile Methodology in Manufacturing?

Agile is a mode of operation that touches all areas of the business (sales, marketing, design, engineering, etc.) and is the next step in the evolution of manufacturing methodologies. Driven by the robustness of data available, the capabilities of today’s technology, and the market conditions in which we operate.

Agile manufacturing is driven by market conditions and responding to them as they are in the present. Advances in technology, like the rise of machine intelligence platforms, and data collection have aided in its adoption. Collecting and using the wealth of data available to manufacturers and then sharing that data across all sections of your business illuminates areas that once relied on guesswork. Data-driven decision making allows your business a laser-like focus on those elements that bring direct value to you and your customers, even as those areas of value change. This approach works really well where a rapid response to customer demand and can set you apart from your competitors.

Some Advantages of Agile:

- Improve productivity across the entire organization

- Improve customer satisfaction with products

- Adapt quickly to changing market conditions

The quick answer here is “slowly”. You need to lay the proper foundations for this process in order to get the maximum benefit. As this methodology is highly informed by data, making sure you are collecting high-quality and highly accurate data is a key first step. Agile methodology allows you to take the guesswork out of your process, but you need to know what you expect from the data and what you are looking for. What are some ways you can communicate with your customers to ensure you understand what they are looking for now?

Some industries are still getting value from a lean approach, particularly ones working within more rigid regulations. However, the post-COVID world is an agile world and it is time to shift focus from eliminating waste to using the data and small, quick-moving teams to be more responsive to market demands.

Go Beyond Lean. Get Agile Webinarur Director, Simon Drexler P.Eng. MBA, hosted a webinar examining the difference between lean and agile manufacturing that goes into more detail.

You can watch that webinar here: Go Beyond Lean. Get Agile.

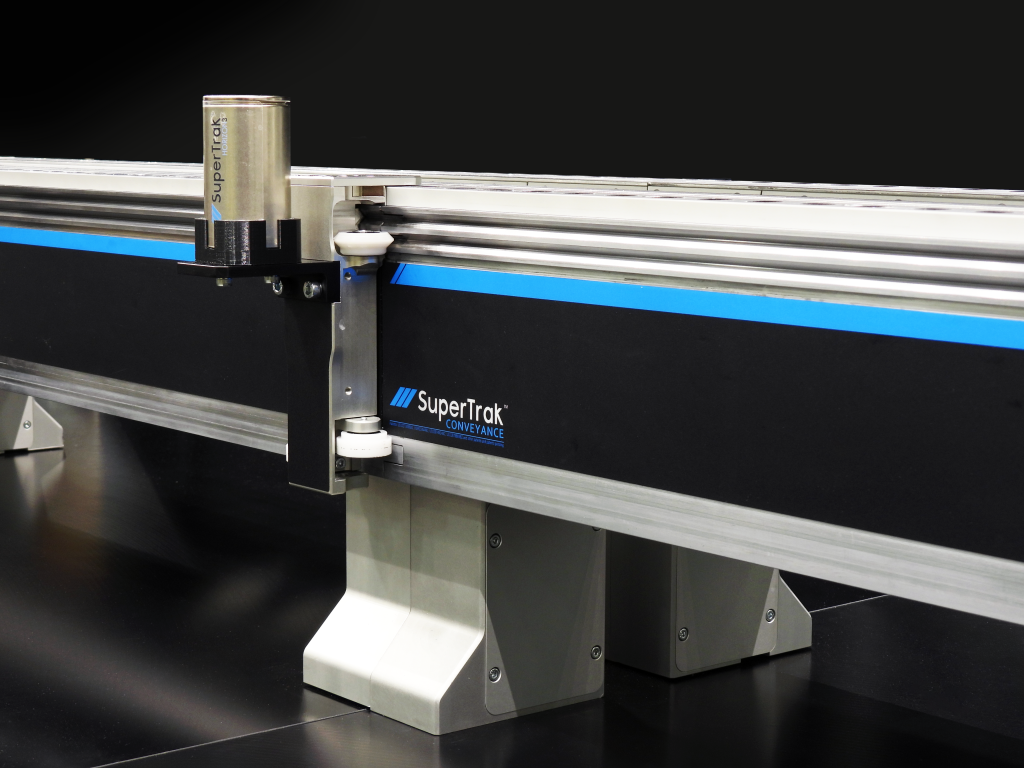

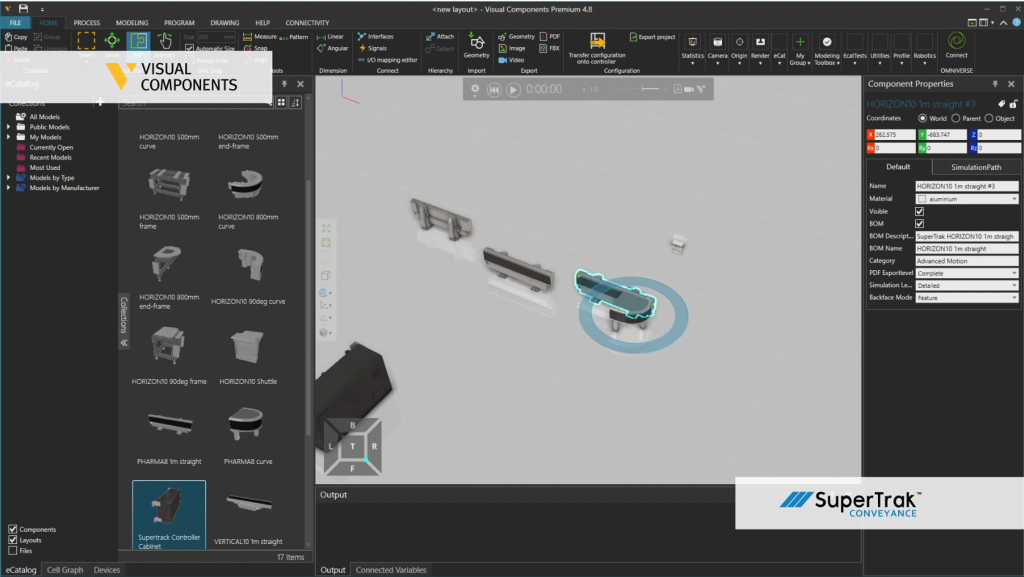

We at SuperTrak CONVEYANCE™ have modeled our own business using agile methodologies to ensure we are responding to our customer needs in real-time. We know that industrial automation processes are changing rapidly and need more flexibility than they have had in the past.

You can learn more about the products our customers have told us they need here: SuperTrak GEN3.