Automated systems can be complex to develop and get to production. Typically, each process requires extensive engineering and customization to meet application requirements.

System complexities are leading to the creation of a higher functioning standard system component to enable faster project cycles. This standardization is a benefit because it provides functionality that has already been tested and verified. The function is basically accessed like a service. Now you only need to know how to use it; you do not have to invest time to understand how it works.

Engineering complexities are now significantly reduced leaving less room for error and enabling a faster path to production without compromising the functionality of the system.

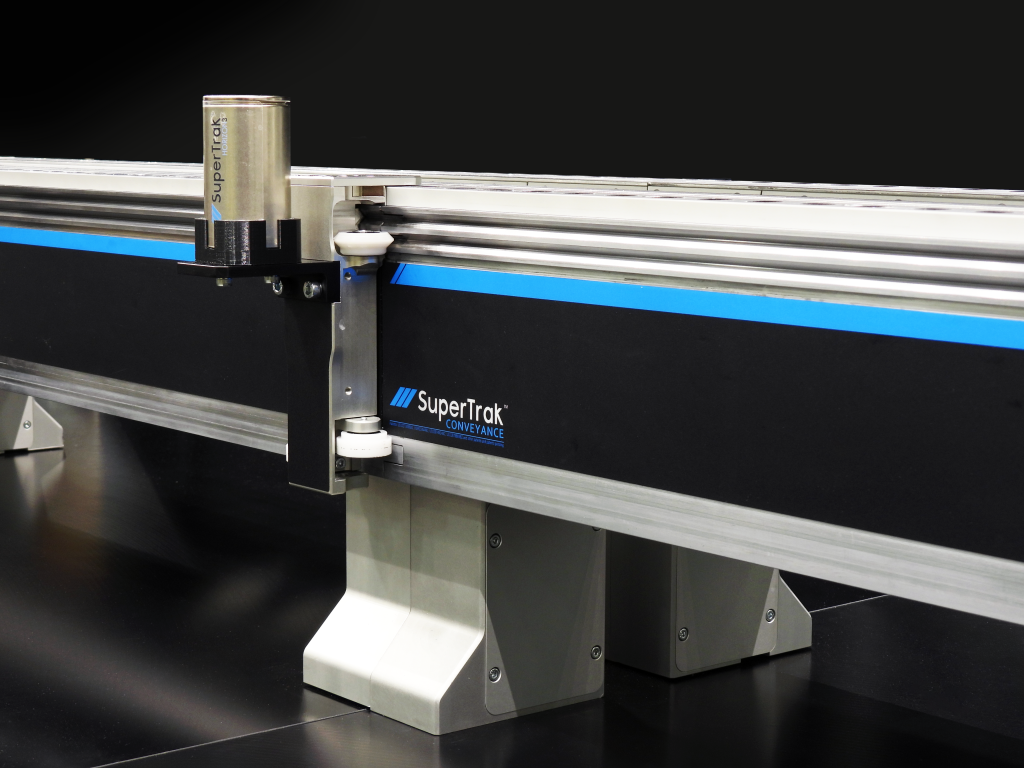

A recent example of this is where ATS’s Life Sciences team utilized SuperTrak GEN3™ as the foundation to design, build and deliver two automated manufacturing systems that are expected to enable the production of 10 million COVID 19 test kits per month. Due to the urgency, these lines are expected to be delivered within a 4-month time frame. In this case, SuperTrak CONVEYANCE™ was the primary enabler to meet the required shortened lead team. Read the full press release here.

How does a standard foundation platform like SuperTrak CONVEYANCE minimize engineering time? TrakMaster™ software, the user interface, provides key tools to enable efficiencies and reduce complexity.

The three main areas are:

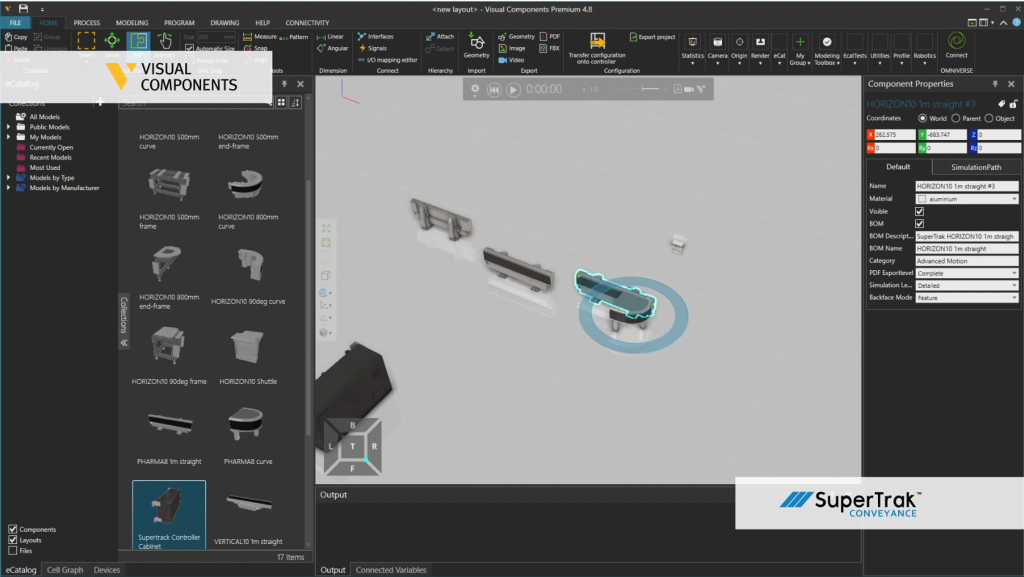

1. Simulation

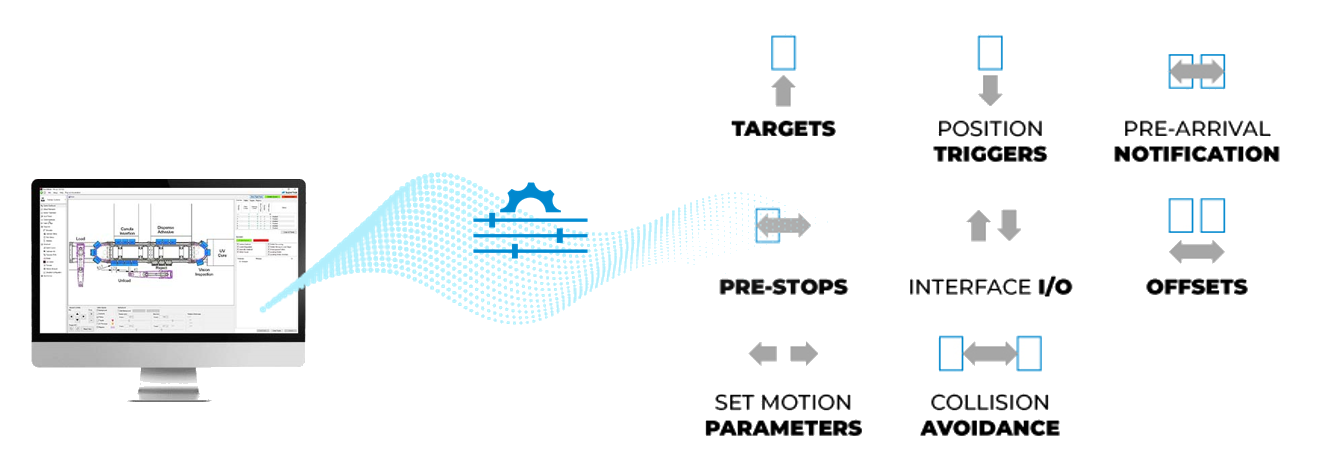

2. Configuration

3. Diagnostics

TrakMaster™ simulation enables better designs

Understanding application requirements is a critical requirement to create effective designs. Problems often arise when unknowns are encountered during the design phase. Because the functionality of the conveyance is also the process flow, simulation provides a way to properly understand and optimize both.

One of the key advantages of using smart conveyance, the term used to describe how the SuperTrak platform drives productivity, is being able to utilize the motion that is already available in the Trak. This allows considerable complexity to be removed from station tooling and robotics. You can learn more about that here.

With TrakMaster software, the simulation will help the designer align functionality with the application requirements so that the design phase can begin with significantly more insight to understand what needs to be designed and what can just be configured.

Watch the video below to see how the intuitive graphical interface offers performance optimization tools to enhance your processes.

TrakMaster™ configuration enables high-performance automation

Twenty years of development and implementation on over 600 systems have allowed the SuperTrak team to identify the functionality that is used over and over again in smart conveyance applications. This capability has now been integrated into the system, so that it can be configured for each application rather than programmed, saving considerable engineering time.

With TrakMaster software, functionality like collision avoidance, position triggers, target and offset teaching, access to motion parameters, I/O availability, pre-arrival notifications, and others allow powerful capability to be configured, removing extensive hours of PLC programming.

Watch the video below to see how TrakMaster unlocks the platform’s integrated functionality to remove risk and engineering time by utilizing tested and proven capability.

Enable better machine interaction with TrakMaster™ diagnostics

Effective machine interaction is essential to running productively. Downtime happens for many different reasons, but having insight into the system is critical to getting back up and running fast.

Watch the video below to see how TrakMaster provides diagnostics tools that allow users to access fault details with recovery recommendations; monitor and optimize section temperatures, power consumption, and station cycle times; and troubleshoot system hardware.

Powerful automation with less risk is enabled by SuperTrak CONVEYANCE™ and TrakMaster software by minimizing custom engineering to utilize simulation, configuration, and diagnostics.

Click here to learn more about TrakMaster™ software and request a sample simulation of your processes.