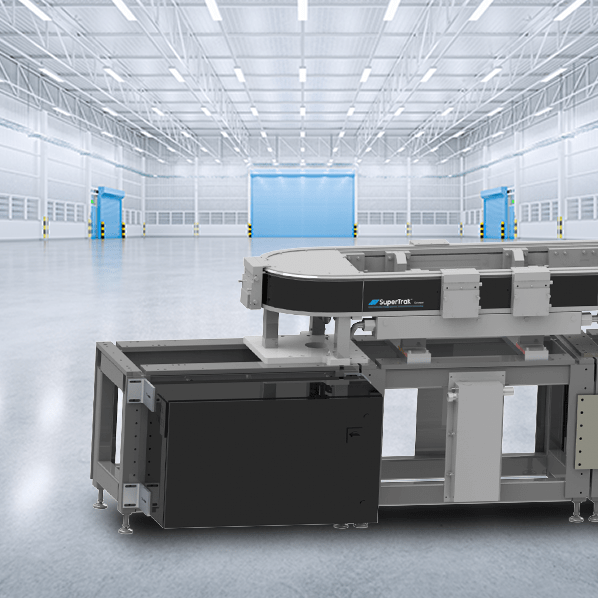

Leaner Automation and Factory Floor Space Optimization

Your factory layout and floorplan – how you use your space — have an enormous impact on the overall success of your automation project. One of the major costs and factors that impact your overall ROI is how much floor space you need to operate.

Unfortunately, traditional conveyance systems leave application engineers and designers with limited options when it comes to reaching the required performance level in the available floor space. These traditional systems often have a large footprint within your space and do not scale easily.

At SuperTrak CONVEYANCE™, we understand these challenges. Over the course of 20 years in business, our team of engineers have designed multiple configurations to help you maximize your factory layout and floor plan to accommodate your unique application needs.

Reduce floor space and improve productivity.

Learn more about how one company reduced their floor space 44% and improved OEE by using Smart Conveyance.

How Reshoring Affects Factory Floor Space.

Where your operations are physically located can also impact your factory layout and floor plan. More and more manufacturers are reshoring operations to North America and Europe. These manufacturers are realizing many benefits, like reduced shipping times for consumers, less environmental impact, and a decreased risk of tariff and trade-related costs. To achieve this, manufacturers are utilizing more technology to increase productivity and balance higher operational costs.

The trade-off for reshoring efforts is the cost related to greater use of floor space for equipment. Designers and builders must be increasingly creative in how they use the limited amount of space available on the factory floor while still maintaining the level of production required to meet business goals.