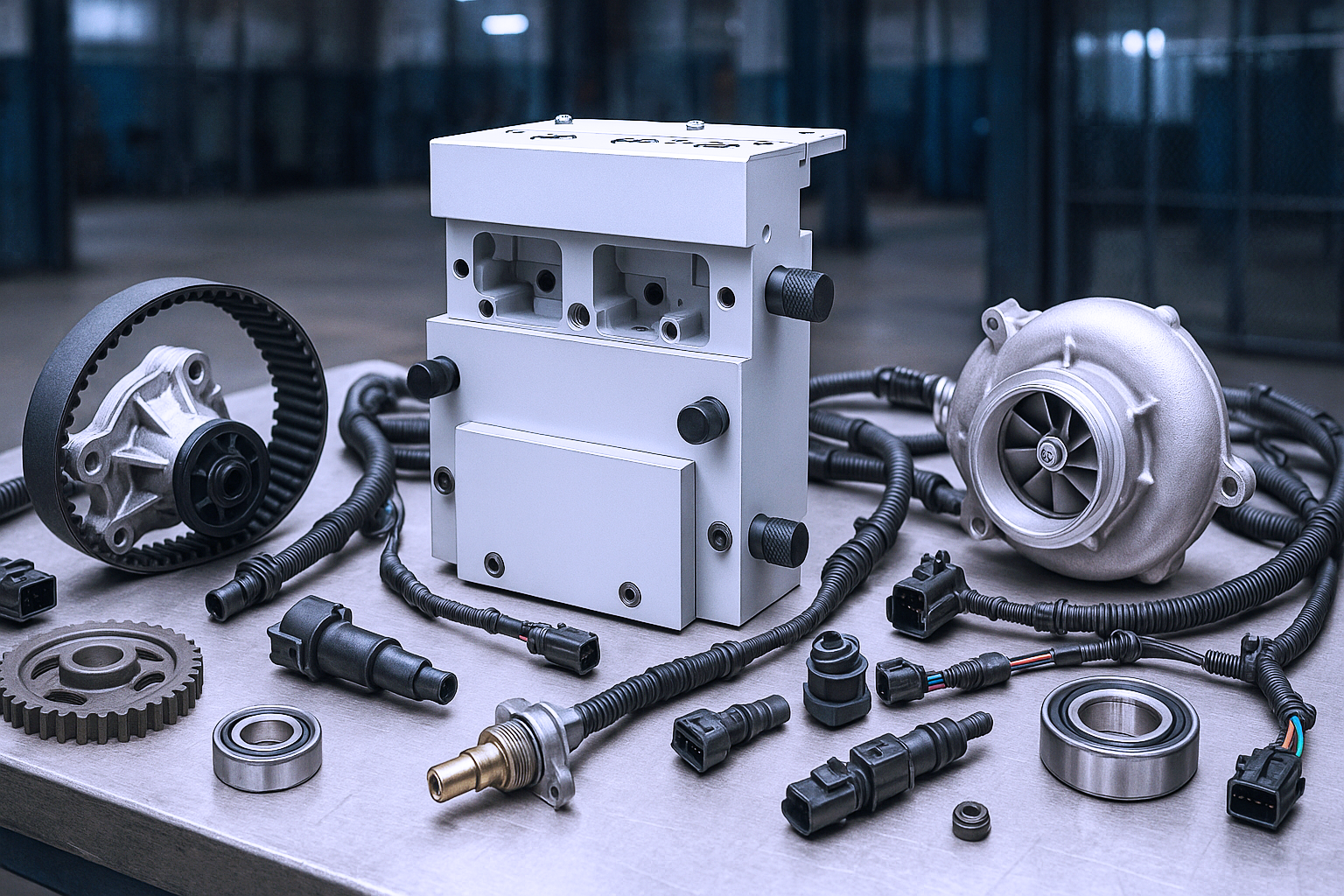

Mechanical component assemblies

Mechanical components are used in industries like automotive, aerospace, construction, HVAC, and industrial machinery.

Machines serve multiple functions, such as assembling pressure gauges, sensors, and Tier 1 automotive components (mirrors, lights, motors, keys, EDU & ECU parts, hairpin preparation).

Common machine processes include:

- Loading/assembling parts

- Welding (including ultrasonic)

- Magnetizing, gluing, pressing

- Labeling, printing, marking

- Inspecting, testing, rejecting

- Packaging and unloading

High precision is required, with some processes needing repeatability within ±0.05mm.

Tray handling is essential for managing parts between machines, including void elimination.

The challenges solved

The most common challenges of such a manufacturer are cost efficiency and high yield. Finding a leaner solution for a complex process is the key to building a viable production line within cost and space constraints, and early simulations are often required to ensure that throughput expectations are met.

The ultimate goal for Smart Conveyance in such applications is leaner automation, provided that it achieves similar or higher throughput and comparable cost to a machine-based standard conveyance system. SuperTrak CONVEYANCE™ brings value by enabling complex motion that can vary at each process step and sometimes become part of the process itself, thereby reducing the need for tooling or stations and increasing the number of process steps possible at a single station or location. As this motion is controlled by software, carrying or adding several products on the same line becomes possible with reduced efforts, and traceability of products becomes possible with the identification of each shuttle.

Leaner automation

Larisys Industries successfully implemented an assembly machine based on a 4m SuperTrak VERTICAL10™ system for a wiring harness application. The machine’s size is estimated to be half that of a standard conveyance solution, and the line’s accessibility is vastly improved to facilitate maintenance.

“The SuperTrak technology is disruptive because of its speed, precision, compact design and capability to be easily configurable.” – Larisys Group.

SuperTrak CONVEYANCE™ Users Showcase Their Machines in Action:

WIKA Polska SGF

Assembling a wide range of pressure gauges in short cycles

(SuperTrak HORZON10™ distributed by Bosch Rexroth under the brand name Active Mover™)

ATS Industrial Automation

Digital twins of SuperTrak CONVEYANCE™ based machines for digital commissioning and

digital shadowing.

HARRANDT

Efficient and precise assembly, as well as inspection and measurement of small and micro parts.