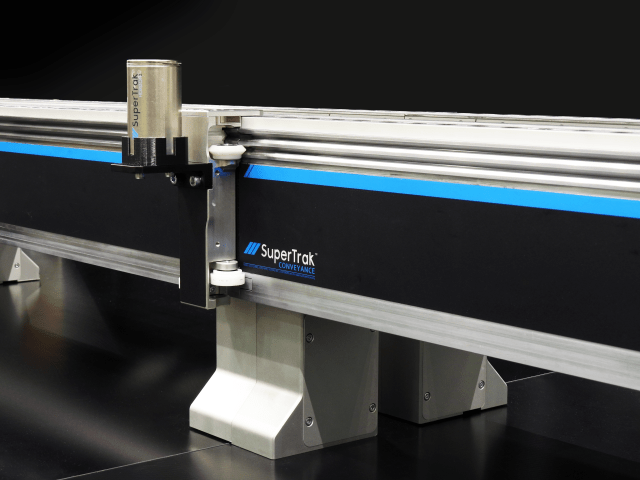

Visual Components is a powerful, flexible and easy-to-use 3D platform to design manufacturing systems in a faster, easier and more collaborative way. You can now use Visual Components to design your SuperTrak CONVEYANCE™ based lean manufacturing automation. Move faster from concept to reality and reduce engineering complexities and risks—all without sacrificing performance.

The Need for Simulations

Designing more cost-effective, space-saving manufacturing automation using smart conveyance can sometimes be challenging. When shuttles move asynchronously, their interaction with tooling and stations becomes complex.

Motion simulations early in the design phase remove engineering complexity and allow system designers to optimize design and performance for a better return on investment.

Using Visual Components, machine builders can now build SuperTrak CONVEYANCE™ based automation faster and understand the final machine size in a 3D environment. They can also demonstrate how their manufacturing line will operate earlier in the design using the embedded Visual Components motion simulation tools.

Start Designing a SuperTrak CONVEYANCE™ Based System in Visual Components

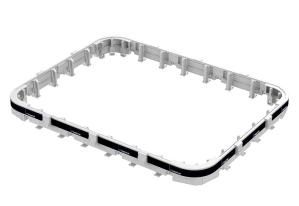

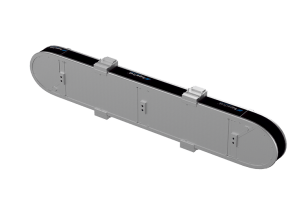

The Visual Components eCatalog now includes all Supertrak HORIZON10™ and SuperTrak VERTICAL10™ configurations.

Visual Components also includes features to help design and simulate faster, such as:

- Drag and drop SuperTrak™ sections and components in the Visual Components 3D environment

- Quick-snap connections and duplicate sections

- Set up shuttle motion, targets, and release

- Access primary shuttle motion simulation parameters (speed, acceleration, etc…)

Download the latest Visual Components eCatalog today and start designing your SuperTrak CONVEYANCE™ based automation!

Do I Still Need TrakMaster™?

Yes! While Visual Components is useful to design and simulate a full machine in 3D, the TrakMaster software™ remains the full-featured software enabling you to unlock the power of smart conveyance. It includes:

- Motion and electrical power simulation using accurate physics models, to optimize processes, evaluate performance requirements, and understand energy consumption of your SuperTrak™ system.

- Simple configuration of SuperTrak’s integrated functionality, for both simulated and real tracks, to remove risk and engineering time by utilizing tested and proven capabilities.

- Diagnostic tools for fault handling and recovery, system status, and highlighting station metrics (cycle time, shuttle transfer, etc.) for optimization and improved OEE.

After designing your full automation in the Visual Components 3D environment, we recommend simulating your SuperTrak™ configuration in TrakMaster™ for a more detailed understanding of shuttle motion, performance statistics, and power consumption. This will guide the final choice of power supplies, shuttle configurations, and other critical parameters needed for your physical SuperTrak™. The configuration used in this simulation will then be available to configure a real track and diagnose your SuperTrak™ integration.

Do not hesitate to contact the SuperTrak™ team at team@supertrakconveyance.com to discuss your simulation needs and to receive free SuperTrak CONVEYANCE™ design support!