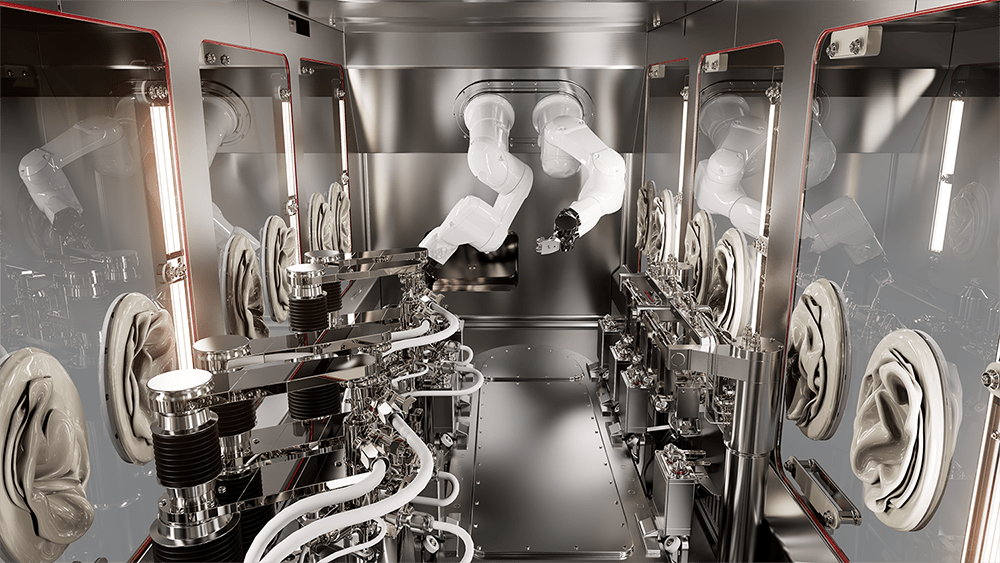

SuperTrak PHARMA8™ is a magnetic conveyor designed for Grade A aseptic environments

SuperTrak PHARMA8™ is able to carry up to 8.5kg per shuttle. This stainless-steel asynchronous conveyor with easily cleanable surfaces enables wipe-down and vaporized hydrogen peroxide (VHP) decontamination that will meet FDA and EMA requirements.

The independent shuttle control of SuperTrak PHARMA8™, combined with up to 30m/s² acceleration and +/-0.01mm repeatability, allows machine builders to reduce repetitive tooling and decrease the size of the isolator.

SuperTrak PHARMA8™ is the new standard for aseptic processing

Machine builders and manufacturers can design, develop, and deploy fill/finish automation solutions while reducing engineering complexities and risks without sacrificing performance.

Specifications, Components and Configuration

Designed to meet FDA and EMA requirements, SuperTrak PHARMA8™ has stainless steel outer surfaces and hermetic seals suitable for Grade A spaces and is ideal for life science and pharmaceutical manufacturing.

SuperTrak PHARMA8™ makes operations simpler.

This magnetic conveyor owes its proven reliability to its unique design, including limited moving parts and a shuttle that can be removed or replaced within 60s. Automation in aseptic environments can now be leaner thanks to SuperTrak PHARMA8™.

A Smaller Size for Aseptic Environments

- Integrated functionalities enable more performance in a more compact machine

- Index shuttles quickly to eliminate the number of tooling parts required

- Increase throughput using the system’s repeatability to remove stopper cylinders and locate tooling

Integrated Functionality

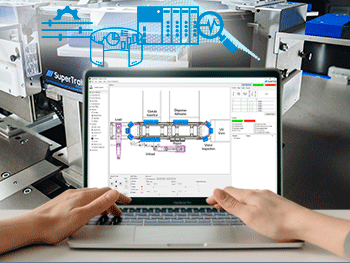

The SuperTrak CONVEYANCE™ platform is a Smart Conveyance technology that provides value by incorporating several features into one platform.

Integrated functionality means less complexity and less automation tooling, allowing for faster market time.

A sample of integrated functionality includes:

- Collision Avoidance.

- Target Routing.

- Pre-stops.

- Define regions for specific motion dynamics.

Industry Applications

Based on over 25 years’ experience deploying Smart Conveyance solutions, SuperTrak PHARMA8™ is setting the new standard for aseptic processing.

Popular applications include:

- Fill and finish – precise batch control with easily cleanable surfaces for wipe down and vaporized hydrogen peroxide that will meet FDA isolator requirements.

- Testing and development – useful for double barrel-injector applications where recirculation of parts is needed, or various batches are being run.

Resources

Simplify design & integration.

Use the SuperTrak CONVEYANCE™ integrated functionality to reduce complexity and risks.

Reduce machine size.

Reduce floor space and improve productivity using SuperTrak CONVEYANCE™.

Medical & Pharmaceutical.

Simplify engineering and get to market faster using SuperTrak CONVEYANCE™ products.

Get in Touch

Fill out the form below to get in touch with a SuperTrak CONVEYANCE™ expert.