A compact magnetic conveyor leads to leaner manufacturing automation.

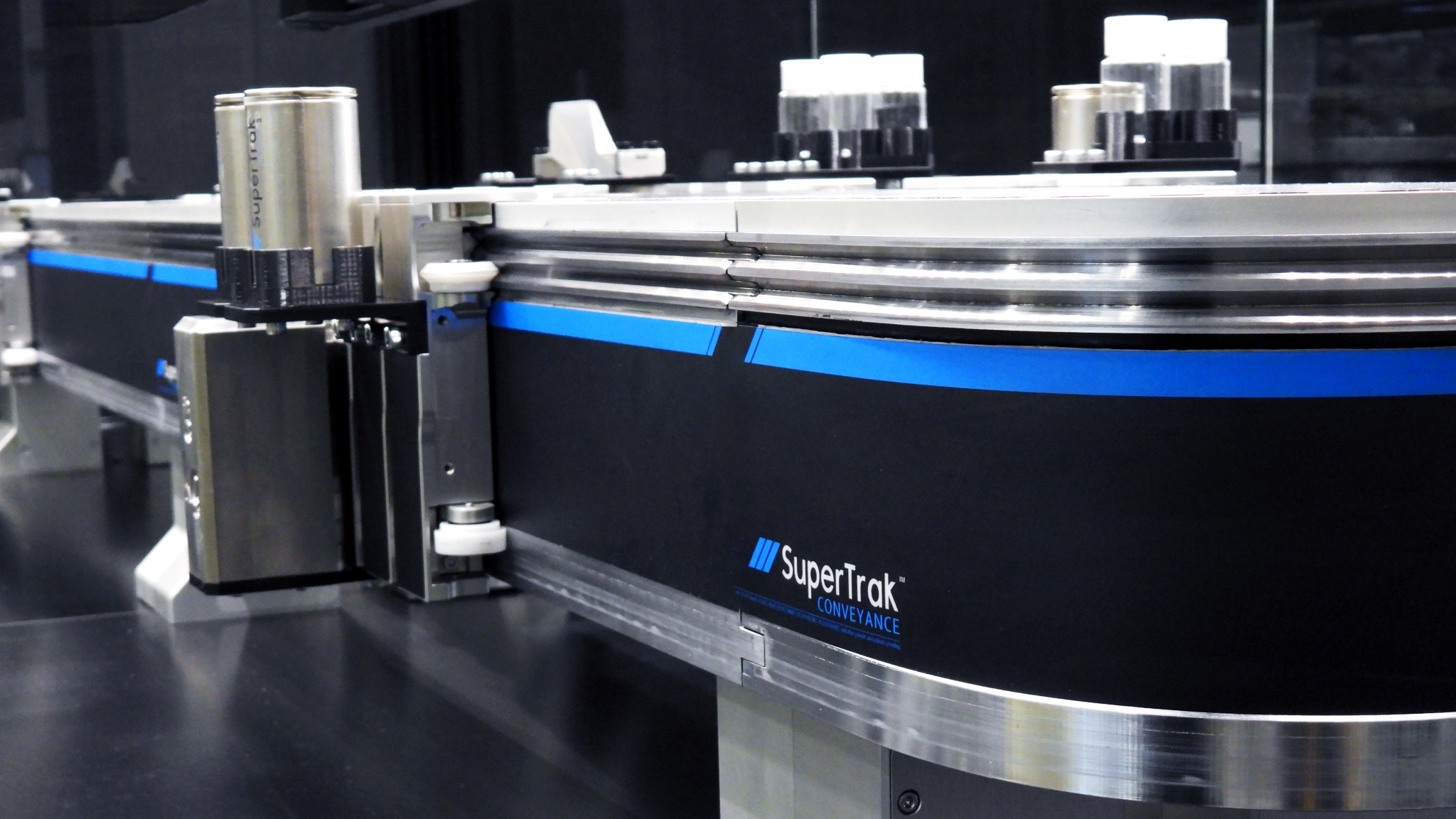

The independent shuttle control of SuperTrak HORIZON3™, combined with up to 10G acceleration and +/-0.01mm repeatability, allows machine builders to reduce the size of assembly and packaging machines.

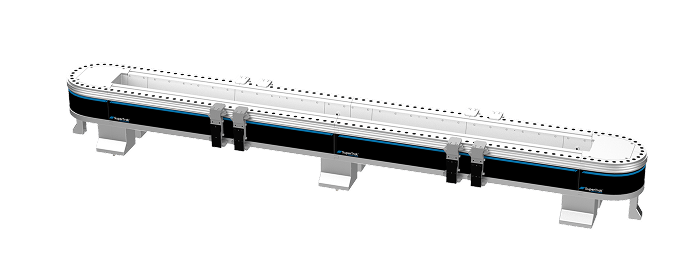

SuperTrak HORIZON3™ is the new standard for packaging and small products assembly.

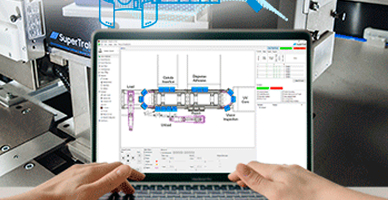

Machine builders and manufacturers can design, develop, and deploy compact assembly and packaging automation while reducing engineering complexities — all without sacrificing performance.

Specifications, Components and Configurations

Designed to serve fast, complex, and scalable lean assembly and packaging automation, SuperTrak HORIZON3™ is an asynchronous conveyor available in various system lengths.

Independent Shuttle Control

Independent Shuttle Control

Each shuttle’s properties can be controlled independently.

Speed: up to 4 m/s

Speed: up to 4 m/s

Improved speed and less time spent in motion.

Precision: +/- 0.01 mm repeatability

Precision: +/- 0.01 mm repeatability

Fewer add-ons needed, leading to shorter cycle times.

SuperTrak HORIZON3™ makes operations simpler.

This compact magnetic conveyor owes its proven reliability to its unique design, including limited moving parts, a mean time to repair shorter than 1 hour, and a shuttle that can be removed or replaced within 60s. Packaging automation can now be leaner thanks to SuperTrak HORIZON3™.

Benefits

Explore Other Products

Start a New Project & Get a Quote

Increased precision means leaner automation as it reduces:

- the amount of stop and locate tooling

- the required engineering effort

- the burden on operations to maintain complex tooling

Use SuperTrak CONVEYANCE™ high precision and low settling time to simplify the design and operations of the final assembly machine.