A high-performance magnetic conveyor for leaner manufacturing automation.

The independent shuttle control of SuperTrak HORIZON3™, combined with up to 10G acceleration and +/-0.01mm repeatability, allows machine builders to reduce the size of assembly and packaging machines.

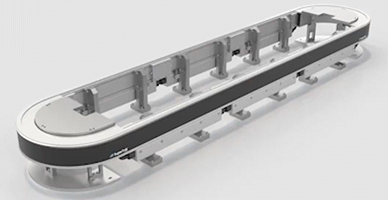

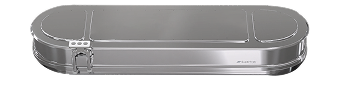

SuperTrak HORIZON10™ is the new standard for industrial and medical device assembly.

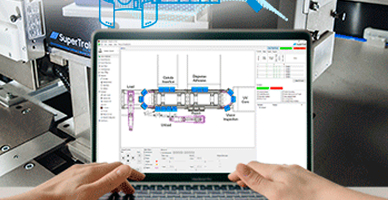

Machine builders and manufacturers can design, develop, and deploy lean assembly automation solutions while reducing engineering complexities and risks—all without sacrificing performance.

Specifications, Components and Configurations

Designed to serve fast, complex, and scalable lean assembly and automation, SuperTrak HORIZON10™ is an asynchronous conveyor available in various system lengths.

Independent Shuttle Control

Independent Shuttle Control

Each shuttle’s properties can be controlled independently.

Speed: up to 4 m/s

Speed: up to 4 m/s

Improved speed and less time spent in motion.

Precision: +/- 0.01 mm repeatability

Precision: +/- 0.01 mm repeatability

Fewer add-ons needed, leading to shorter cycle times.

SuperTrak HORIZON10™ makes operations simpler

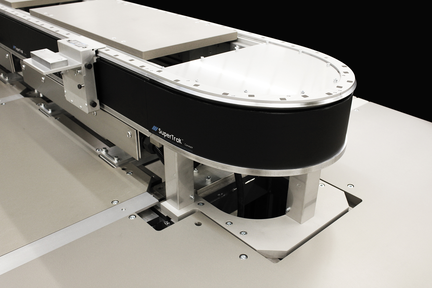

This magnetic conveyor owes its proven reliability to its unique design, including limited moving parts, a mean time to repair shorter than 1 hour, and a shuttle that can be removed or replaced within 60s. Manufacturing automation can now be leaner thanks to SuperTrak HORIZON10™.

Benefits

Explore other products

Start a new Project & Get a quote

Increased precision means leaner automation as it reduces:

- the amount of stop and locate tooling

- the required engineering effort

- the burden on operations to maintain complex tooling

Use SuperTrak CONVEYANCE™ high precision and low settling time to simplify the design and operations of the final assembly machine.