High-Volumes. Flexibility.

In our rapidly transforming landscape, packaging machine builders face new challenges and opportunities. Customer preferences are changing, innovative products and variants are frequently required to address market needs, and new packaging lines must accommodate more complex packages of various sizes and shapes. High-volumes need to be maintained while being able to change batches and quantities sometimes on a daily basis.

However, while production expectations may become more complicated, floorspace comes at an ever-increasing premium cost, often making expansion of current processes unsustainable.

Fast. Configurable.

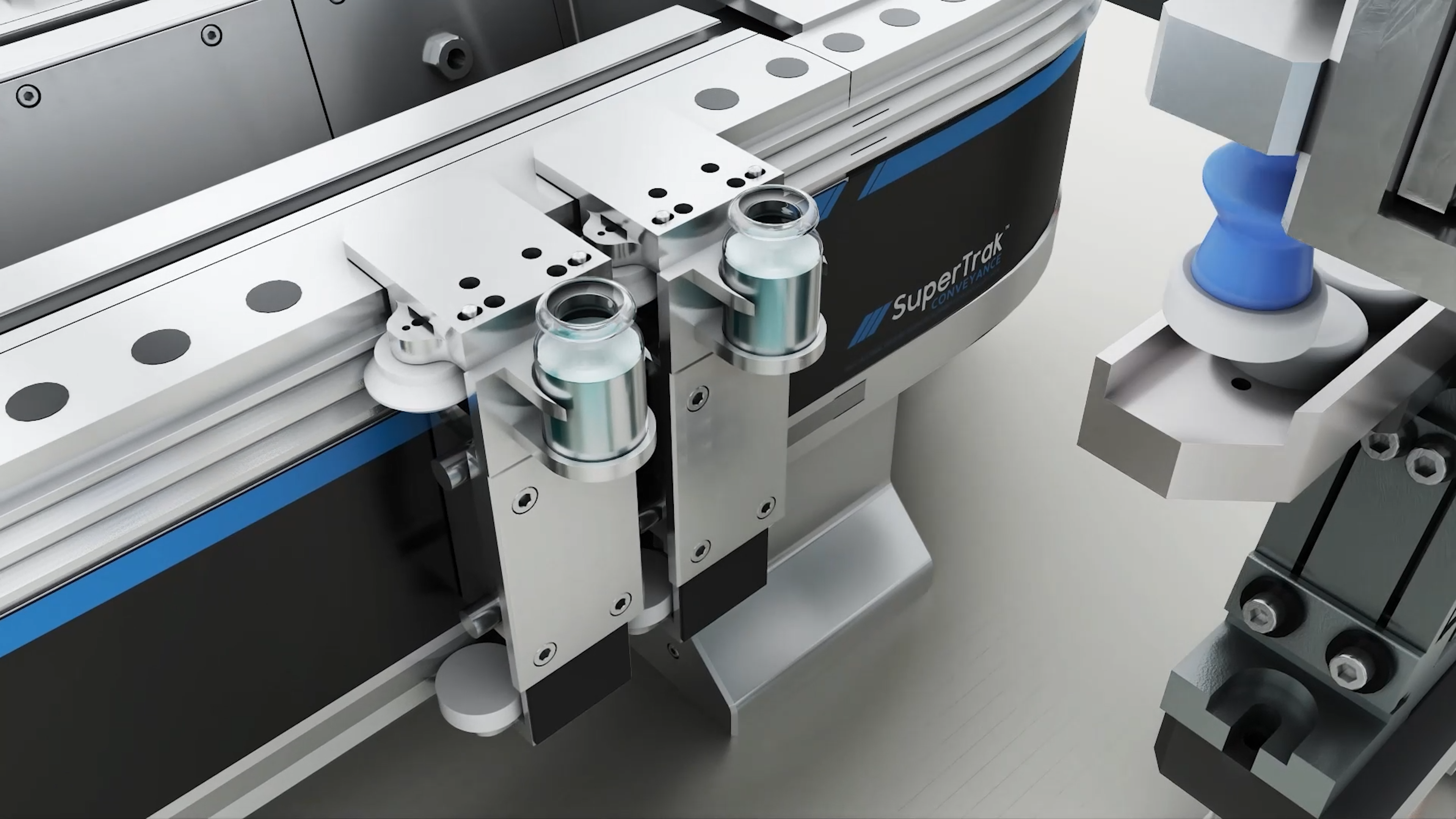

The SuperTrak CONVEYANCE™ platform boasts rapid acceleration speeds of up to 4 m/s and maintains industry-leading settling times. It employs both high-speed synchronized motion and point-to-point motion on the same platform. For packaging machine builders, these capabilities translate to increased throughput in a reduced space.

In addition, the SuperTrak CONVEYANCE™ motion is configured by software, making change-overs easier than ever.

Maximize Throughput. Minimize Footprint.

Thanks to its independent shuttle control, SuperTrak CONVEYANCE™ achieves high performance in the minimum amount of space by reducing tooling and station redundancies. The software varies the pitch between products and eliminates voids, accommodating an increasing diversity of sizes and shapes. The platform also offers various configuration options to meet your unique space challenges for packaging equipment.

Speed, Flexibility and Usage in One Platform

On top of high speeds and increased flexibility brought by software configuration, SuperTrak CONVEYANCE™ platform brings unprecedented reliability and provides data showing cycle times and statistics for the entire process. Monitoring your system’s throughput down to station-specific takt times and motion delays is another way to ensure your system is used most efficiently.

Our customers use our TrakMaster™ software to monitor their processes’ performance consistently. And with SuperTrak’s limited number of moving parts, its mean time to repair is shorter than 1 hour, and its shuttles can be removed/swapped within the 60s, getting the maximum usage of your machine has never been easier.