Ok, so ghosts and goblins still may be the only things you find in the graveyard this Halloween because the indexing dial table isn’t actually dead. In fact, it’s not really going anywhere. It still has an effective place in the automation world, but hey, it’s Halloween and it’s fun to come up with spooky ways to get your attention. But there is a new option available that may change the way you think about the dial and the benefits they can offer you.

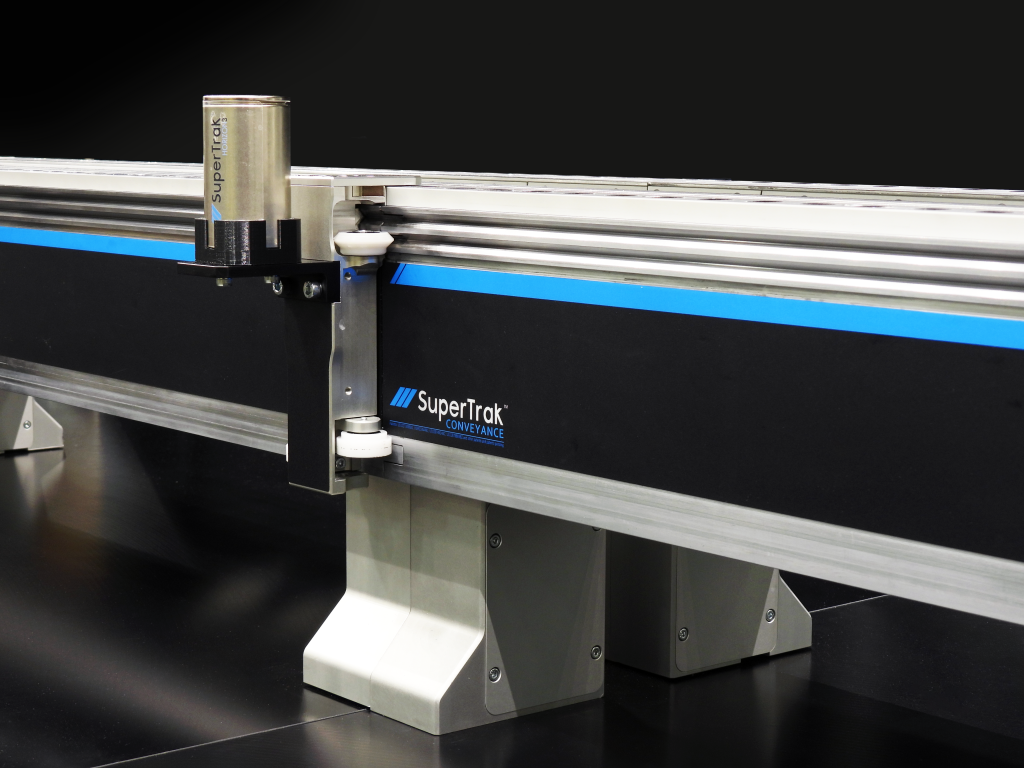

As we get ready to launch the new SuperTrak GEN3™ 90 DEG motor section we’ve been hearing references to an indexing dial or a servo dial, and want to point out the differences and where you may benefit from using one over the other.

Why the Indexing Dial Table Isn’t Headed to the Graveyard

Application Engineers already know that traditional dials bring a lot of value. They are very good at saving floor space and packing a lot of functionality into a smaller footprint, particularly when you have consistent station times and processes that require up/down operations such as:

- Screwing

- Pressing

- Testing

But the Dial is Limited in its Functionality

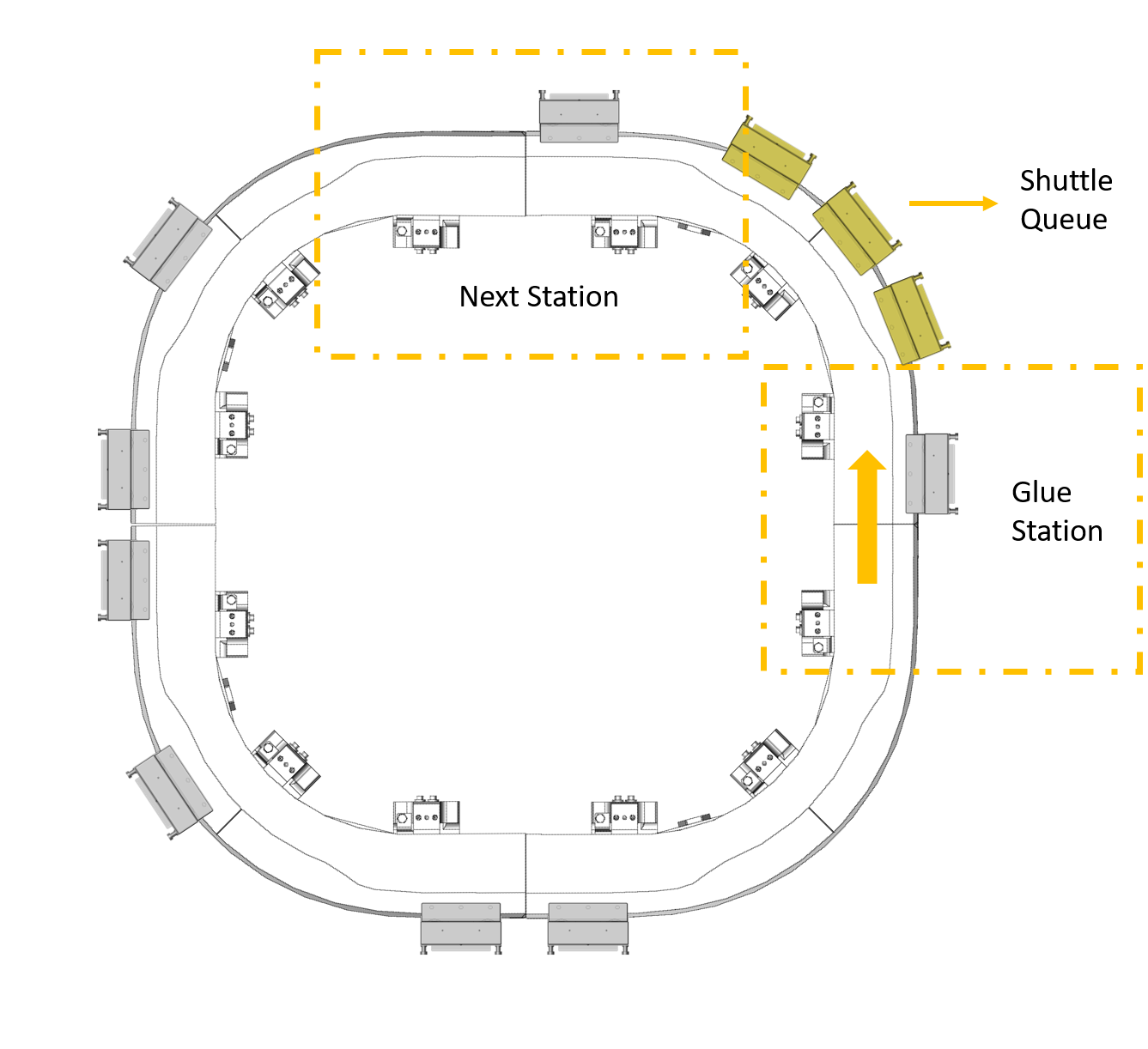

The problems with traditional indexing dial tables are encountered, however, when the station times are not consistent. Or the process requires more advanced operations. Gluing, for example, usually requires a period of time for curing, a testing operation may take extra time to complete, or an assembly operation requires top and bottom access.

Another thing to consider is scalability. If you plan to increase throughput in the future, most often you would need to acquire an additional dial to accommodate for additional processes.

The Case for Smart Conveyance

The SuperTrak GEN3 90 degree, joins the lineup of existing SuperTrak GEN3 configurations including the 500mm curve and 800mm curve. This newest option enables unique system configurations that can provide numerous efficiencies from a floor space perspective and allow you to easily expand your system by adding more trak sections as required.

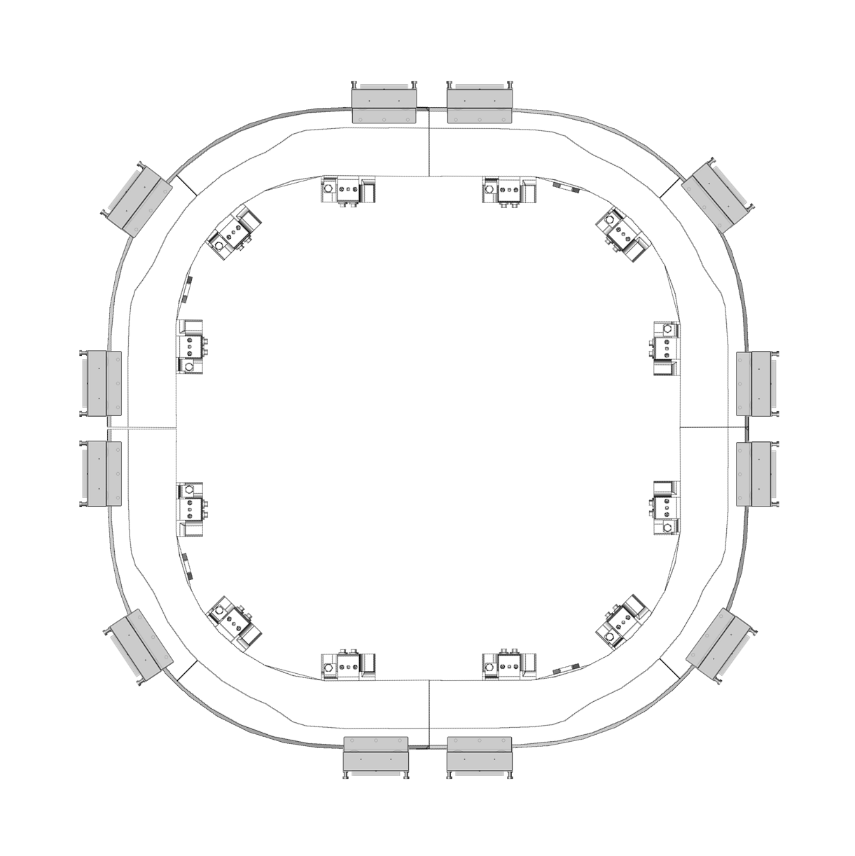

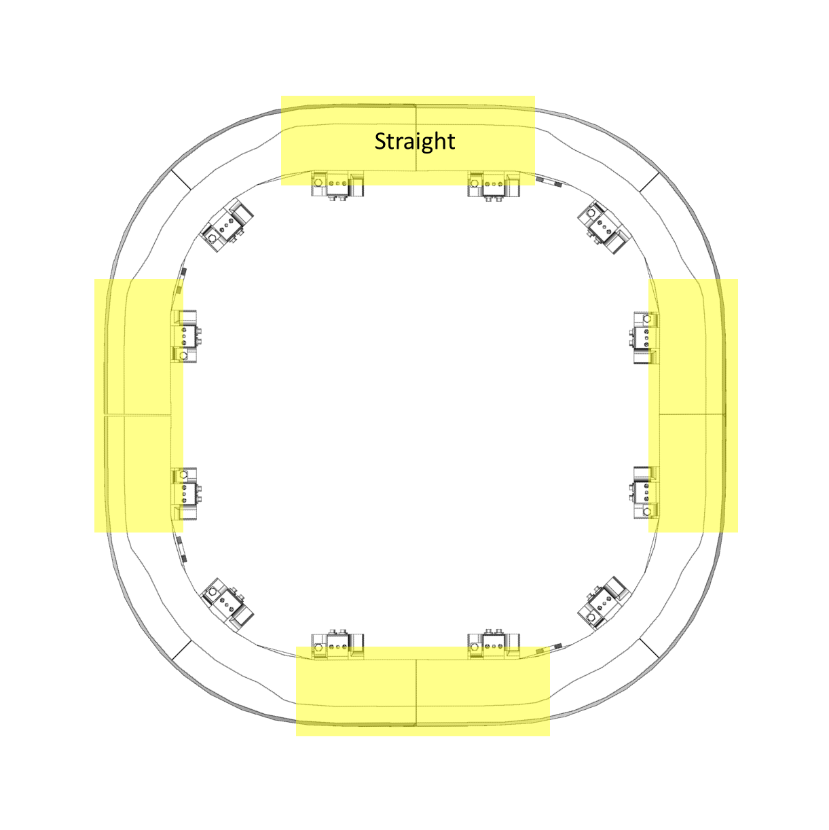

One such configuration is dial like, utilizing four 90 DEG sections together.

The advantage of a configuration like this parallels a traditional indexing dial , but now the capability exists to be asynchronous, and you have access to the shuttle’s tooling plate from above, below, and in front.

Let’s think back to that gluing application I mentioned where curing is required. The operation can be completed and rather than wait at the station to cure (like a synchronous process), the shuttles can queue at the next station. If the system is designed properly, the queue time can be the exact time required for curing. Not only do you now get the floorspace benefits associated with dials, but your cycle time is reduced.

Individual Shuttle Control

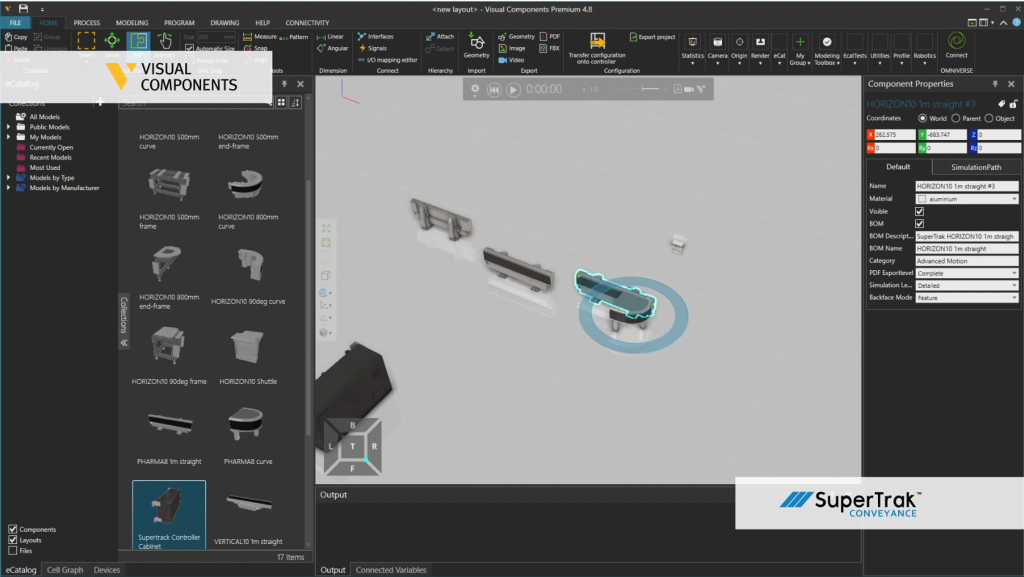

Each shuttle can also be programmed with individual velocities and accelerations for gentle (unsecured part) or aggressive (secured part) motions. Our simulation capability with TrakMaster Software™ enables this level of system insight and design which normally isn’t available with traditional conveyance.

Reduced Cycle Times

Cycle times can now be optimized due to the advantages of the asynchronous operation (independent shuttle control). Alternate between 1 up and multi-up operations and, as discussed, utilize queues for any operation that requires time to set or cure.

Floorspace Reduction

The shuttle (tooling fixture) can be accessed from the top, bottom, side, or the front, creating a lot of configuration options for mounting tooling on the outside or on the inside of the Trak. Also, the dial-like configuration is not circular (it is more of a squared circle) so you can take advantage of the straight locations to simplify tooling alignment, particularly in multi-up situations, while still having the freedom to mount stations anywhere.

There’s no question that indexing dials aren’t dead and will continue to be a mainstay in automation for a long time, and I don’t see it going anywhere….almost like Freddie Kruger or Jason (sorry, marketing has really encouraged the Halloween references!).

The new SuperTrak GEN3 90 DEG takes the original dial concept and amplifies it.

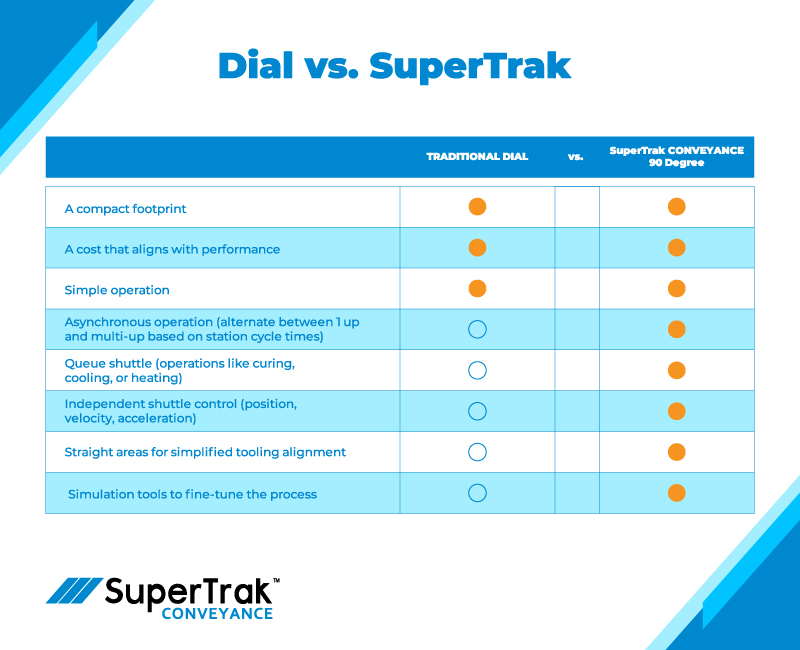

With an indexing dial, you get:

- A compact footprint

- A cost that aligns with performance

- Simple operation

With a SuperTrak dial configuration, you get:

- A compact footprint

- Easily expand or redeploy as processes change

- Asynchronous operation – alternate between 1 up and multi-up based on station cycle times

- Queue shuttles for operations like curing, cooling, or heating.

- Independent shuttle control (position, velocity, acceleration)

- Straight areas for simplified tooling alignment

- Simulation tools to fine-tune the process

- Simple operation – SuperTrak GEN3’s integrated features provide a means to achieve high-performance capability with less effort

- A cost that aligns with performance

Want to learn more about smart conveyance and how it can decrease machine development timelines and improve overall automation ROI? View our 2-part FastTrak webinar series here.

Thanks for reading and Happy Halloween everyone! Enjoy the dial-licious treats!