Conveyance impacts the automation design and performance of your system more than any other singular component.

In order to better understand the mind of system designers we work with, we conducted a survey which yielded some surprising results, mainly that 85% of designers don’t think about conveyance early in the automation design phase.

It’s our take that conveyance should steer your automation design, not struggle to fit into it. When you think of conveyance early on, you’re thinking of a long-term, big-picture strategy at the start – not piecing things together as you grow. Through our work with several automation integrators, we’ve seen that this approach not only provides better OEE (Overall Equipment Effectiveness) but a better ROI on your total automation investment.

Based on our survey findings, system designers typically believe they need to understand independent processes (or stations) prior to selecting a conveyance method. Essentially, conveyance was viewed by respondents as a secondary step that comes after the processes have all been identified and laid out. With this approach of considering conveyance later in the design process, however, the result is often duplication of tooling, overly complex programming, and ultimately, a longer time to market and a larger investment than necessary.

Conveyance Connects Everything

Motion

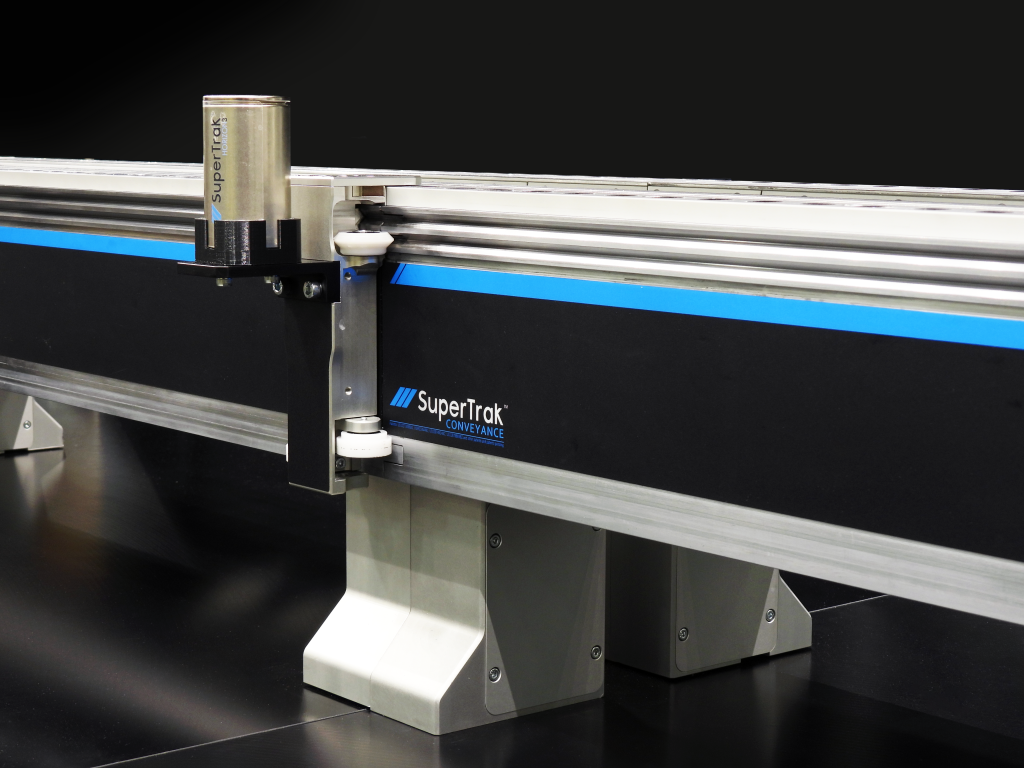

Conveyance is a form of motion and is responsible for getting parts in and out of stations as fast and as efficiently as possible. Smart Conveyance determines how the product moves from one process to the next, where it stops, and when it needs to be redirected. Understanding how motion can be used to create a better system, by using it as an axis of motion, for example, can help you when you consider conveyance at the start of your automation design.

Footprint

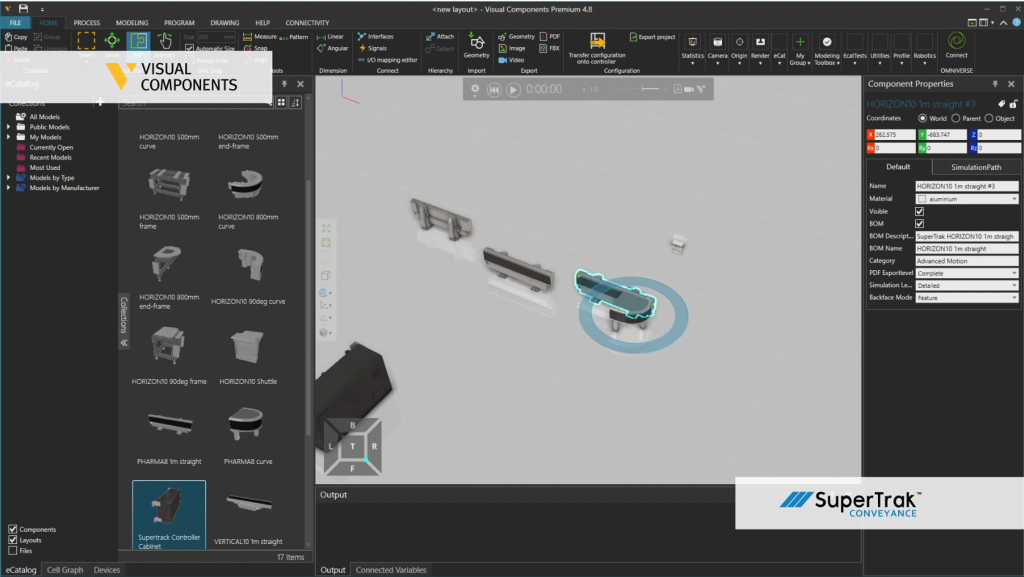

The size of your system, the shape, the amount of tooling required – all these items in your automation design are impacted by the conveyance that you choose and will impact the amount of space required on the factory floor. Using a simulation early in your design will simplify identifying potential bottlenecks and highlight opportunities to increase efficiencies by clearly illustrating how changing certain variables within the system can impact functionality and Overall Equipment Effectiveness (OEE). Using throughput as an example, if the conveyance platform is not optimized, you may require more tooling stations and a larger overall system size to reach your required Parts Per Minute (PPM). Increased tooling and footprint end up costing time and money in the long run, which is why you should consider conveyance early in the design process.

OEE

Operational Equipment Effectiveness (OEE) is typically defined by availability, performance, and quality. Conveyance has a direct tie to OEE because it is the one piece of equipment that connects everything – if your conveyance is down, your entire system is down. If designed properly, your conveyance also enables your parts to spend less time in motion and more time in process, thus improving the performance of your overall system. Using cycle time as an example, because of the asynchronous motion offered by SuperTrak GEN3™, a system can work on multiple shuttles at once to improve the cycle time of the process at a particular station. Duplicating tooling to work on more than one shuttle or part within a station on the SuperTrak GEN3™ platform is quite simple when there is adequate space.

Lastly, from a quality standpoint, Smart Conveyance enables your fixtures to align with station tooling as accurately and as many times as possible. Thinking of conveyance early on helps you get the best OEE out of your system.

Conveyance Keeps Long-Term Growth in Mind

When you think of conveyance – specifically Smart Conveyance – as a foundation and not an afterthought, you may be able to eliminate some process stations and reduce your factory footprint, which will change your overall automation design. Putting conveyance first means spending less time reworking your automation design and spending more time in motion.

Check out the webinar FastTrak Machine Development with Smart Conveyance (P.1) to learn more about how Smart Conveyance can increase efficiency and improve system design to get you to market faster.

Automation Design and Scaling

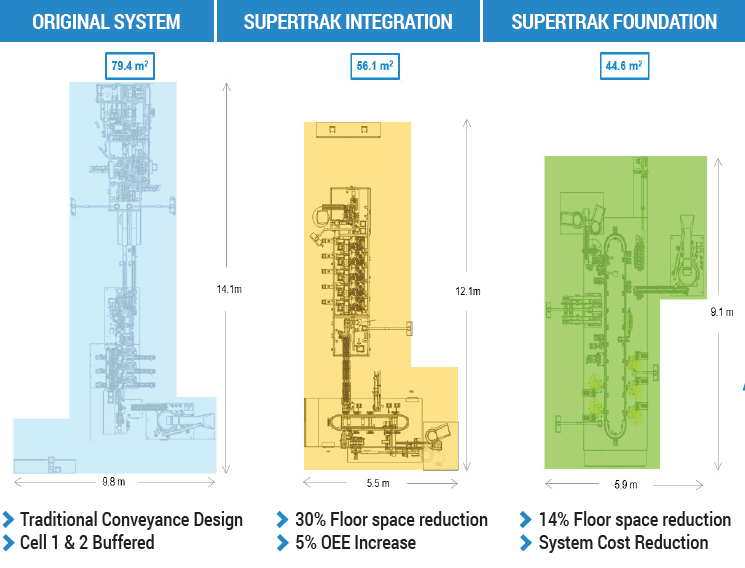

Keeping a growth mentality in mind at the start of your automation design makes scaling your business that much easier in the future. Our case study Reducing Factory Footprint by 44% is a clear example of how not considering conveyance early on can cost you time and money.

In this example, the initial system design didn’t consider potential future growth and used traditional conveyance as the foundation for their automation. As demand for the product grew, the company needed to increase throughput but were restricted by the available floorspace in their facility. Once they thought about conveyance as a foundation and made the switch to Smart Conveyance, they were able to drastically reduce their factory footprint. By simply integrating SuperTrak GEN3™ into their existing system, their factory footprint was reduced by 30%. In the next phase of growth, the original system was completely replaced the SuperTrak GEN3™ platform. By thinking about their conveyance from the onset and by using Smart Conveyance as the foundation for their automation, the business was easily able to scale their system and their factory footprint was reduced by 44% from their initial automation design.

Conveyance is a Fundamental Component of Automation Design

Three main resources impacted by the design of an automation system are people, process, and infrastructure.

The factory of the future might be able to be successful without these three elements, but considering the innovations in our industry today, no automation company can be successful without keeping each of these main resources in mind.

People

In our survey, when asked what the main thing respondents looked for when researching new technologies, 77% of them said they wanted technical information that relates to the operation of the technology. Your people are impacted by the design of your automation system because they may need to advance their skill sets or bring on new team members to run the system. Outside of day-to-day operations, your people are also impacted by the requirement to perform maintenance and spare part installation—both of those skills vary based on the type conveyance system.

Process

The efficiency of the processes in your automation system are directly impacted by your conveyance system. Your conveyance system is what ties those processes together, and different components drive different process requirements. By selecting conveyance at the start of your automation design, you’ll have a better understanding of the minimum number of processes needed to achieve an ideal throughput.

Infrastructure

To state the obvious, different conveyance options come with different levels of upfront investment. The type of conveyance you choose impacts tooling requirements, speed or cycle times, and physical space – all of which cost money. That’s why it’s important to keep long-term growth in mind, because while some systems may be less expensive upfront, others may cost you more when scaling in the future.

Help Conveyance, Help You

As Jerry McGuire said, “help me, help you!”; conveyance design and automation design are pretty much the same. The most simplistic way to define conveyance is, “the movement of products from one location to another”. But when you consider conveyance early in the design phase, it can be so much more than that. Smart Conveyance enables manufacturers to build and deploy high-performing automation that meets the needs of today while keeping future goals in mind. As a system designer, as soon as you start to think about conveyance as the foundation or starting point for your automation design, you will start to achieve your performance goals and ROI requirements.